Description

Model: Temescal BJD-1800 3-Cathode Sputter System

Category: Sputter

Original Equipment Manufacturer: Temescal/ TFE

Condition: Used in Caltech University before Dec., 2018. We sell them at AS IS,WHERE IS condition. Refurbished or Refurbished&Upgraded are optional at extra cost and time.

Price: Please make an offer, Terms – Prepay

Quantity: 1

Valid Time: Subject to prior sale without notice

Lead Time: Immediately after receipt of payment.

Location: U.S.A.

Warranty: No warranty for the AS IS,WHERE IS condition.

Description:THIS INFO CAME WITH THE SYSTEM WHEN WE BOUGHT IT. NO GUARANTEE OF THE INFO BELOW. JUST FOR YOUR REFERENCE.

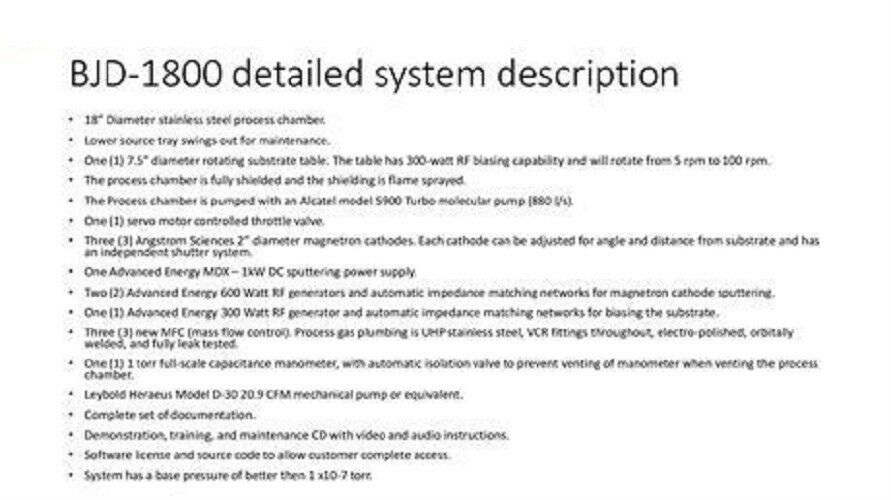

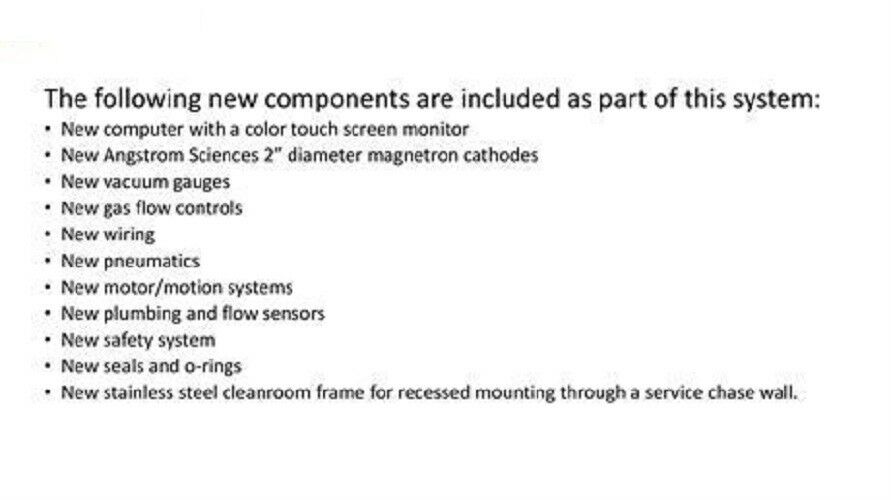

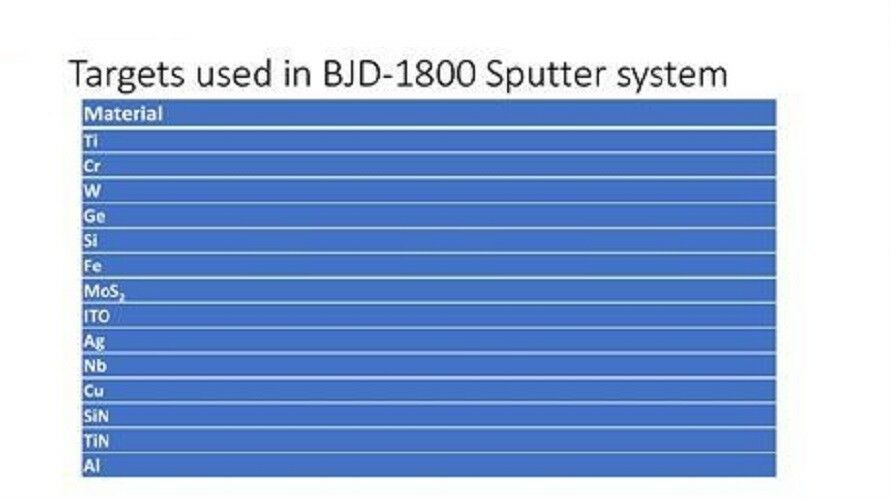

Temescal BJD-1800 3-Cathode Sputter System, System Specs: (see picture). Excellent condition. The system was fully operational prior to deinstallation in a Fab in Silicon Valley.

Pls contact us via email sales@semistarcorp.com if you are interested in the following. These are subject to prior sale. These are only for end user. Appreciate your time.

| 1 | 000-0000// AMAT E5500 HOIST ENDURA 5500 SPUTTER TNAN [ASIS] |

| 2 | 0020-09031, AMAT, INSULATING WASHER – ONLY. Part from P5000 SPUTTER & TR |

| 3 | 0020-09911 / AMP-266-009, CARRIER, SPUTTER / APPLIED MATERIALS AMAT |

| 4 | 0020-09911, AMAT, Applied Materials CARRIER, SPUTTER, From P5000 Sputter kit |

| 5 | 0020-09912 PIN LIFTING SPUTTER, lot of 7 |

| 6 | 0020-09933 / GAS DISTR. PLATE SPUTTER / APPLIED MATERIALS AMAT |

| 7 | 0020-10527, AMAT, Applied Materials, SPUTTER PIPE , Teflon |

| 8 | 0021-11382 / MAGNET ASSEMBLY, ENDURA PVD SPUTTERING / APPLIED MATERIALS AMAT |

| 9 | 00-680909-00 / RAM BELLOWS ASSY,PRESSURE PLATE, ,SPUTTER,00-680909-00 / NOVELLUS |

| 10 | 0200-09086, AMAT, Applied Materials, QUARTZ RING 200MM SPUTTER ETCH |

| 11 | 0200-09090; RING QUARTZ 200MM SPUTTER ETCH BGR, Applied Materials (AMAT) |

| 12 | 0200-09608, AMAT, Applied Materials,SHLD QUARTZ,200MM,SPUTTER ETCH |

| 13 | 04-716797 /MULTI RANGE DC SPUTTERING POWER SUPPLY M2000,M2I / VARIAN VPW2870P5-S |

| 14 | 1,000 pounds of pure silicon sputtering targets polysilicon poly-silicon |

| 15 | 1021-12-151 / WEST COAST QUARTZ RING, 8″ SPUTTER CERAMIC / WEST COAST QUARTZ |

| 16 | 10538 ANATECH SPUTTERING SYSTEM HUMMER 10.2 |

| 17 | 115-0101// HITACHI 03E-0601, E-120 ION SPUTTER |

| 18 | 116-0503// AMAT APPLIED 0200-09087 QTZ RING 150MM SPUTTER |

| 19 | 119-0301// HONEYWELL E5500 11″ DB ENDURA 6″ SPUTTERING TARGET |

| 20 | 21″x 6″ Cadmium Tin Alloy Rotary Sputtering Target 99.9% (Cd)66.5(Sn)33.5 Wt% |

| 21 | 304-200225 Rev A, Sputtering |

| 22 | 324-0202// AMAT APPLIED 0020-39554 HARD STOP, WAFER LIFT, SPUTTER |

| 23 | 342-0101// AMAT APPLIED 0020-09912 LIFTING PIN, SPUTTER |

| 24 | 342-0101// AMAT APPLIED 0020-09912 LIFTING PIN, SPUTTER |

| 25 | 35mm Slide-#467-1961-Sputterer Spring |

| 26 | 3648 Sputtering Materials Inc. 03069440002-A Boundment Backing Plate RND: 4″ |

| 27 | 3744281 – Leybold Heraeus – CONTACT ELEMENT – FOR SPUTTERING 011/110 |

| 28 | 4″ Glass For Viewport UHV Sputtering |

| 29 | 6 inch diameter round sputter gun |

| 30 | 771 gram 27Oz 99.95% Niobium Columbium metal sputtering target element 41 sample |

| 31 | 786 gram 28Oz 99.95% Niobium Columbium metal sputtering target element 41 sample |

| 32 | 8 inch Reflective “Splatter&Adhesive” sputtering Reactive Shooting paper |

| 33 | 9.5″ Spit & Sputter Dying Perch Muskie Topwater Lure Handcrafted 6.5 Oz |

| 34 | 99.99% Aluminum 8.7/8″x 3.3/8″x 0.310″ Sputter Target Approx.103 Grams |

| 35 | 99.995% Titanium Sputtering Target Plate Diameter 57mm 2.24” Thick 5mm |

| 36 | 99.995% Titanium Ti Sputtering Target Disc Plate Diameter 150mm Thick 5mm |

| 37 | 99.995% Titanium Ti Sputtering Target Disc Plate Diameter 85mm Thick 5mm |

| 38 | 99.995% Titanium Ti Sputtering Target Plate Diameter 2” Thick 10mm |

| 39 | 99.995% Titanium Ti Sputtering Target Plate Diameter 70mm Thick 5mm |

| 40 | 99.995% Titanium Ti Sputtering Target Plate Diameter 75mm Thick 3mm |

| 41 | A&N Chain Clamp Sanitary Pipe Ultra Low Vacuum Sputtering Deposition Chamber |

| 42 | Advanced Energy 10kW Magnetron Drive Power Supply Sputtering MDX 2226-000-F |

| 43 | ADVANCED ENERGY 3152283-000A CONTROLS BOARD FOR MDX TYPE DC SPUTTER POWER SUPPLY |

| 44 | Advanced Energy 3157600-003 PEII Reactive Sputtering PSU 1100V 10kW 40KHz 208VAC |

| 45 | Advanced Energy 3157600-004 PEII Reactive Sputtering PSU 10kW 208VAC |

| 46 | Advanced Energy 3157600-004 PEII Reactive Sputtering PSU 1100V 10kW 40KHz 208VAC |

| 47 | Advanced Energy AE Ascent 40KW DC Sputtering Power Supply |

| 48 | ADVANCED ENERGY AE MAGNETRON CATHODE SPUTTERING T HEAD 6″ WAFER 3151701-010 |

| 49 | advanced energy AE MDX 2.5 2500w dc sputtering power supply single phase amat |

| 50 | Advanced Energy MDX 1K Magnetron Power Supply 1Kw, 115VAC, Single-Phase, 16A |

| 51 | Advanced Energy MDX 1K Magnetron Sputter Power Supply 1Kw, 115VAC, 1-Ph, 16A |

| 52 | Advanced Energy MDX 2.5K 3152224-031A DC Sputter Power Supply 200-208V, 220-240V |

| 53 | Advanced Energy MDX 5K Magnetron Drive 5 kW Sputter Power Supply 2011-000, USA |

| 54 | Advanced Energy MDX 5K Magnetron Drive 5kW Sputter Power Supply 2011-000-E USA |

| 55 | Advanced Energy MDX II 3152256-005F DC Sputter Power Supply 18KW 400V3-phase 32A |

| 56 | Advanced Energy MDX II 3152256-209C DC Sputter Power Supply |

| 57 | Advanced Energy MDX-1K, 2105 Dc Sputter Power Supply |

| 58 | Advanced Energy MDX-2.5K DC Sputtering Power Supply 2224-006-B Output 500-1800V |

| 59 | Advanced Energy MDX-500 DC Sputtering Power Supply – 6 month wrty. |

| 60 | Advanced Energy Pinnacle 3152352-123B Pulsed DC Sputter Power Supply, 8 KW |

| 61 | Advanced Strategies In Thin Film Engineering By Magnetron Sputtering |

| 62 | Advanced Strategies in Thin Film Engineering by Magnetron Sputtering by Alberto |

| 63 | ADVANCED STRATEGIES IN THIN FILM ENGINEERING BY MAGNETRON SPUTTERING GU MDPI AG |

| 64 | AE ADVANCED ENERGY MDX 1.5K MAGNETRON SPUTTERING DC POWER SUPPLY. 500V 3A |

| 65 | AE Advanced Energy MDX 1.5K Sputtering DC Power Supply |

| 66 | AE Pulsed Plasma PEP-2500 bipolar dc rf sputter power |

| 67 | AJA INTERNATIONAL ST20 RF/DC sputtering source for 2″ x 0.25″ target |

| 68 | AJA INTERNATIONAL ST30-MM , RF/DC HV Sputter Source 3 Inch |

| 69 | AJA Intl Sputtering Target – Iron – 2″ Dia – 1/8″ Thick – 99.95% Pure |

| 70 | Al-Sc 87.5/12.5 wt% Alloy Sputtering Target |

| 71 | Aluminum Al Sputtering Targets – 2.00″ Diameter, 0.250″ Thick – Kurt J. Lesker |

| 72 | Aluminum MRC Chi Inset Sputter Target: Al 99.9+ With Materials certification |

| 73 | Aluminum nitride, AlN – Sputtering Target |

| 74 | Aluminum SEM Sputtering target: Al 99.999% pure, 54mm diameter x 1mm thick |

| 75 | Aluminum SEM Sputtering target: Al 99.999% pure, 57mm diameter x 1mm thick |

| 76 | Aluminum sputter target, Al 99.999% pure 2″ diameter x 0.125″ thick |

| 77 | Aluminum sputter target, Al 99.999% pure 2″ diameter x 0.25″ thick |

| 78 | Aluminum sputter target, Al 99.999% pure 50mm diameter x 3mm thick |

| 79 | Aluminum Sputtering target: Al 99.999% pure, 63mm diameter x 1mm thick |

| 80 | Aluminum Target for Nobler NT 1500 sputter coater |

| 81 | Aluminum, Al – Sputtering Target |

| 82 | Aluminum/Indium sputter target Al/In 1:1 at%, 99.99% pure 3″ dia x 1/4″ thk |

| 83 | Aluminum/Manganese sputter target Al/Mn 99.8/0.2 wt% 3″ diam x 0.25″ thk |

| 84 | Aluminum/Nickel sputter target 50/50 Al/Ni at% 99.99% rod 4.2″ long x 0.5″ diam |

| 85 | Aluminum/Silicon MRC Chi Sputter target: Al/Si 99/1 wt% |

| 86 | Aluminum-doped Zinc Oxide Sputtering Target AZO |

| 87 | AMAT 0010-01994 Rev.001, Magnet Assembly, PVD, Endura, Sputter Chamber |

| 88 | AMAT 0010-09425, Grounding Strap, Assy, Sputter Etch |

| 89 | AMAT 0010-20818 ENDORA 5500, MAGNET, SPUTTER, PVD source |

| 90 | AMAT 0020-00663, Insulator, Source, 11 inch, Ceramic, PVD, Sputter |

| 91 | AMAT 0020-07701 Shield Upper Ti TiN Al Flame Spray Endura sputter Chamber |

| 92 | AMAT 0020-09911 MXP Sputter, Etch Carrier, Wafer lift with 4 Pin |

| 93 | AMAT 0020-09911 SPUTTER CARRIER with 0020-09912 |

| 94 | AMAT 0020-10050 Pedestal, Flat Sputter |

| 95 | AMAT 0020-10050 Pedestal, Flat Sputter |

| 96 | AMAT 0020-10051 Ring, Top Sputter |

| 97 | AMAT 0020-10051, Ring, Top Sputter |

| 98 | AMAT 0020-10527 sputtering pipe, etch chamber, teflon insulator, MXP |

| 99 | AMAT 0020-21467 Adapter Source, PVD Chamber, Sputter, Endura Tool |

| 100 | AMAT 0020-21707 8 Inch wafer hoop, Lifter Endure, PVD sputter |

| 101 | AMAT 0020-21707 8 Inch wafer hoop, Lifter Endure, PVD sputter, CDSL-D-280 |

| 102 | AMAT 0020-21707 8 Inch wafer hoop, Lifter Endure, PVD sputter, CDSL-D-299 |

| 103 | AMAT 0020-24640, 6JMF, Tin clampring, PVD Sputter chamber |

| 104 | AMAT 0020-29719 Pre clean Endura sputter Pedestal quartz chuck |

| 105 | AMAT 0020-29719-PA, Endura, PVD, Chuck, Pedestal, Sputter Chamber |

| 106 | AMAT 0020-29719-PA, Endura, PVD, Chuck, Pedestal, Sputter Chamber |

| 107 | AMAT 0020-62669 SHIELD, APERATURE, B/S SPUTTER |

| 108 | AMAT 0021-11075-001, Endura, PVD, Chuck, Pedestal, Sputter Chamber |

| 109 | AMAT 0021-11382 Magnet Assembly, Endura PVD sputtering |

| 110 | AMAT 0021-76516 Chamber Liner, PVD Sputter, Endura Tool |

| 111 | AMAT 0040-01761 Endura Pre-clean Chamber Body, Sputter, PVD |

| 112 | AMAT 0040-20561 Belljar, Preclean II, Endura, Sputtering Plate |

| 113 | AMAT 0040-20561 Belljar, Preclean II, Endura, Sputtering Plate |

| 114 | AMAT 0040-20561 Belljar, Preclean II, Endura, Sputtering Plate |

| 115 | AMAT 0200-09084 Shield, 125mm, Sputter Etch |

| 116 | AMAT 0200-09088-B Quartz Ring 125MM Sputter Etch |

| 117 | AMAT 0200-09091 Graphite Ring For P5000 Sputter Etch (FCVD02C) |

| 118 | AMAT 0200-09608, Shield Quartz 200mm, Sputter |

| 119 | AMAT 0200-09608-C, Shield Quartz 200mm, Sputter |

| 120 | AMAT 0200-20059 PVD Sputter Liner Clamp, 6″, Aluminum, SMF, STR |

| 121 | AMAT 0200-20061 Insulator, Quartz, 6″, PVD Sputter chamber PCII |

| 122 | AMAT 233-2889-25 AMAT PVD endura clamp ring Sputter chamber |

| 123 | AMAT 6″ ENDURA HEATER ASSEMBLY, PVD SPUTTER CHAMBER |

| 124 | AMAT Applied Materials 0020-09933 Gas Distribution Sputter Plate |

| 125 | AMAT Applied Materials 0020-09933 Gas Distribution Sputter Plate |

| 126 | AMAT APPLIED MATERIALS 0100-20255 RF Sputtering |

| 127 | AMAT Applied Materials 0140-16349 Harness Assembly Sputter Chamber Right |

| 128 | AMAT Applied Materials 0140-16350 Harness Assembly Sputter Chamber Rear |

| 129 | AMAT Applied Materials 0140-16351 Harness Assembly Sputter Chamber Bottom |

| 130 | AMAT Applied Materials 0200-09088-B Quartz Ring 125MM Sputter Etch |

| 131 | AMAT Applied Materials 0200-09088-C Quartz Ring 125MM Sputter Etch |

| 132 | AMAT Applied Materials 0225-34794 Gas Distribution Sputter Plate |

| 133 | AMAT APPLIED MATERIALS QTZ RING, 200mm SPUTTER ETCH, AMAT P/N 0200-09086 |

| 134 | AMAT Endura Sputter Chamber Source Magnet Holder, Lock |

| 135 | AMAT Magnet Assembly, PVD, Sputter, 329947 |

| 136 | AMAT PVD Chamber Lift Assembly, Endura Sputter Chamber, SMC NCDQ2WB63-01-0193US |

| 137 | AMAT PVD Endura sputtering chamber clamp ring |

| 138 | Anatec Limited HUMMER VI Sputtering System |

| 139 | Anatech Gold Sputtering Coating Machine with Vacuum Pump Hummer VII |

| 140 | Anatech Hummer 6.2 Sputtering System |

| 141 | ANATECH HUMMER VI-A SPUTTERING SYSTEM |

| 142 | Anatech HUMMER X Sputter System |

| 143 | Anatech HUMMER X Sputter System |

| 144 | ANATECH HUMMER X SPUTTER SYSTEM |

| 145 | Anelva 32 Point PCB Relay Board For 1015/1013 Sputtering System ILC 1013 |

| 146 | ANELVA 9005-41429 SPUTTER TARGET, PVD, COML, BONDING D164 T4, 5N AI-PURE |

| 147 | ANELVA 9005-41429 SPUTTER TARGET, PVD, COML, BONDING D164 T4, 5N AI-PURE |

| 148 | Anelva Sputtering system ICL-1015 Semiconductor Processing Assembly |

| 149 | Angstrom Sciences 99.999% Copper 8.0″ x 0.25″ Sputtering Target |

| 150 | ANGSTROM SCIENCES NICKEL SPUTTERING TARGET (NI) 99.995% BONDED 8”X.250” |

| 151 | Angstrom Sciences Onyx Intevac Sputtering RM PVD Magnet Assembly |

| 152 | Angstrom Sciences PLux Control – Touchscreen – Magnetron Sputtering |

| 153 | Angstrom Sciences RF / DC PLANAR MAGNETRON SPUTTER GUN, 2″ TARGET |

| 154 | Angstrom Sciences Sputtering Cathode with Aluminum Target, 8″ x 3″ |

| 155 | Anode layer ion source plasma sputtering thin film 2.75″ conflat SHV baseplate |

| 156 | Anode layer ion source plasma sputtering thin film deposition |

| 157 | Antimony, Sb – Sputtering Target |

| 158 | Antimony/Telluride sputter target – Sb2Te3 99.99% pure, 1.00″ diam x 4mm thk |

| 159 | Applied Materials (AMAT) 0020-03597 Spider Sputter etch |

| 160 | Applied Materials (AMAT) 0020-09911 CARRIER, SPUTTER |

| 161 | Applied Materials (AMAT) 0020-10527 Sputter pipe |

| 162 | Applied Materials (AMAT) 0020-10527 SPUTTER PIPE |

| 163 | Applied Materials (AMAT) 0020-10527 SPUTTER PIPE TEFLON |

| 164 | Applied Materials (AMAT) 0020-21707 8″ wafer hoop, Lifter Endure, PVD sputter |

| 165 | Applied Materials (AMAT) 0020-30178 SPUTTER ETCH CARRIER SEMICONDUCTOR PART |

| 166 | Applied Materials (AMAT) 0200-09062 WEST COAST QUARTZ RING COVER 150MM SPUTTER |

| 167 | Applied Materials (AMAT) 0200-09083 SHIELD 150MM SPUTTER ETCH |

| 168 | Applied Materials (AMAT) 0200-09088 WEST COAST QUARTZ RING 125MM SPUTTER ETCH |

| 169 | Applied Materials (AMAT) 0200-09089 RING QUARTZ 100MM SPUTTER12NC:790050202513 |

| 170 | Applied Materials (AMAT) 0200-09090 RING GRAPHITE 200MM SPUTTER ETCH |

| 171 | Applied Materials (AMAT) 0200-09608 SHLD QUARTZ,200MM,SPUTTER ETCH |

| 172 | Applied Materials (AMAT) 0220-10629 KIT, SPUTTER ETCH LIFT ASSY MOD |

| 173 | Applied Materials (AMAT) 0225-34794 GAS DISTRIBUTION PLATE, SPUTTER |

| 174 | Applied Materials (AMAT) 0226-97903 CATHODE KIT TUNGSTEN ETCHBACK/ST SPUTTER |

| 175 | Applied Materials 0010-76306 Bearing, Assy. Sputter AMAT Etch |

| 176 | Applied Materials 0020-09911 Carrier,Sputter |

| 177 | APPLIED MATERIALS 0021-61445 300MM RING, DEPOSITION, CU SPUTTER, BCP (Cu) AMAT |

| 178 | Applied Materials AMAT 0200-09063 RING COVERING SPUTTER 4 |

| 179 | Applied Materials AMAT Heater Loop Sputter CPL 102136614 2600W 400V |

| 180 | Applied Materials Heater Loop Sputter, 102136616, 2600W, 400V CPL |

| 181 | Applied Materials Model:0020-10527 Sputter Pipe for FCVD02C |

| 182 | APPLIED MATERIALS PEDESTAL THICK 200MM GRAPH/QUARTZ SPUTTER ETCH 0020-10518 |

| 183 | APPLIED MATERIALS RING GRAPHITE 200MM SPUTTER ETCH, 91-00331A 0200-09090 |

| 184 | Arbogast Hawaiian Sputter Fuss Fish Lure |

| 185 | Arbogast Hawaiian Wiggler #2 1/2 Sputter Fuss 251 F Frog Skirt Box Pamphlet EUC |

| 186 | Assorted Matzuo Lure lot (3) Prism Shad Spit & Sputter, Zen Double Play Crank |

| 187 | Aurion B-MBT-48 Matchbox Prodik 30kW T300 for RF Sputtering Disposition Chamber |

| 188 | Aviza Technology 188850 150mm Back Sputter Shield Trikon |

| 189 | AZO- Sputtering Target |

| 190 | BALL BEARING, SPUTTERING COMPONENTS, P/N: 100195 |

| 191 | Balzers 150mm Wafer Carousel Assembly LLS 801 Sputtering System |

| 192 | Balzers 200mm Wafer Carousel Assembly LLS 801 Sputtering System |

| 193 | BALZERS 5×10″ Sputtering Target 99.999 Pure 95%Al Aluminum+1%Si+4%Cu BD 483790-T |

| 194 | Balzers 90/92 Coating Materials Sputtering Targets Evaporation Sources Catalog. |

| 195 | Balzers 90-88749 LLS 801 Sputtering System Manual |

| 196 | Balzers BAK 642 Sputtering System |

| 197 | Balzers Coating Materials Sputtering Targets Evaporation Sources 84/86 Catalog. |

| 198 | Balzers D12/45216951 Remote Control for Wafer Sputtering System |

| 199 | Balzers LLS 801 Sputtering System Operating Manual |

| 200 | Balzers Manual Set Unaxis LLS 502 Load Block Metal Film PVD Sputtering System |

| 201 | Balzers MC 515 BK221410-T Magnetron For LLS 502 Sputtering System |

| 202 | Balzers Unaxis Sputter Target AITi Ring ARQ 131 M00-1074/1 01-342081 |

| 203 | Barium sputter target Ba 99.9% purity 2″ diameter x 0.25″ thick |

| 204 | Bayville chemical carbon sputtering target (99.99%) 2″ diameter 0.125″Thk AA-17 |

| 205 | Big End Bearings KOLBENSCHMIDT Sputtering BMW 2.5d 3.0d 24V M57D30 M51D25 E71 X6 |

| 206 | Big End Bearings KOLBENSCHMIDT Sputtering VW T5 Transporter Bus 2,5l Tdi Axe Axd |

| 207 | BIG END BEARINGS Sputtering KS VW Audi Seat Skoda 1, 9L TDI PD AJM AUY ATD atj |

| 208 | Big End Bearings without Cleats Sputtering Glyco 71-3904 0,25mm Oversized 1,2 |

| 209 | Bio-Rad Polaron E6700 Turbo vacuum coating ?sputter evaporation bell jar coater |

| 210 | BioRad Polaron E7000 Freeze Fracture Sputter Coater Vacuum Chamber Bell Jar |

| 211 | Bismuth Selenide , Bi2Se3 – Sputtering Target |

| 212 | Bismuth sputter target, 99.999% pure Bi, 2.00″ diam x 0.25″ thk |

| 213 | Bismuth Sputtering Target, 3.00″ D x 0.25″ thick, 99.999% pure |

| 214 | Bismuth Telluride, Bi2Te3 – Sputtering Target |

| 215 | Black Wheel Cap for 2021 2022 KIA Sorento for 20-inch Sputtering Wheel Rim |

| 216 | Bohemia Jihlava JS14071, 10-Inch Crystal Vase with Platinum Gold Sputtering |

| 217 | Bohemia Jihlava JS16914, 10-Inch Crystal Vase with Blue/Gold Sputtering |

| 218 | Bonfire Sheet Sputtering Sheet Bonfire Board Seat Heat Welding Authentic |

| 219 | Bonfire Sheet Sputtering Sheet Bonfire Board Seat Heat Welding Authentic |

| 220 | Boron sputtering target B 99.5% purity, 2″ diameter x 0.125″ thick |

| 221 | Boron, B – Sputtering Target |

| 222 | Brian CHAPMAN / Glow Discharge Processes Sputtering and Plasma Etching |

| 223 | BUHLER SPUTTERING TARGET 6333032265 LOPH-14120-001 Target 320x100x8 |

| 224 | Bumper Sticker “Our ’38 Ford Is Sputtering” 1938 Classic Collector 14″ |

| 225 | Burbank Sportscards – World’s Largest Selection |

| 226 | BZ-1730-21-A – Leybold Heraeus – CONTACT ELEMENT – FOR SPUTTERING 011/110 |

| 227 | Cadmium SEM Sputtering target: Cd 99.99% pure, 57mm diameter x 0.25mm thick |

| 228 | Cadmium sputtering target Cd 99.99% pure 2″ diam x 0.25″ thk |

| 229 | Cadmium Sulfide, CdS – Sputtering Target |

| 230 | Calcium (reactive) sputter target Ca 99.9% 2″ diam x 1/4″ thk |

| 231 | Calcium Fluoride, CaF2 – Sputtering Target |

| 232 | Calcium Manganate, CaMnO3 – Sputtering Target |

| 233 | Calcium Ruthenate, CaRuO3 – Sputtering Target |

| 234 | Calcium Ruthenium-Titanate, Ca(Ru0.5Ti0.5)O3 – Sputtering Target |

| 235 | Calcium Titanate, CaTiO3 – Sputtering Target |

| 236 | Canon / Anelva 912-7060 Sputter Ion/Noble Ultra High Vacuum Pump 400 L/sec |

| 237 | CANON / ANELVA C-7300,PVD, SPUTTERING SYSTEMS “2010 vintage” , wafer size 12″ |

| 238 | Canon Anelva 1015i Sputtering System – 6″ |

| 239 | CANON ANELVA Sputtering Equipment C-7530 HF |

| 240 | Canon/Anelva C7100 PVD, SPUTTERING SYSTEMS *SJ3 |

| 241 | Carbon SEM Sputtering target: C 99.999% pure, 54mm diameter x 1mm thick |

| 242 | Carbon sputtering target C 99.999% 2″ diameter x 0.25″ thick ACI ALLOYS |

| 243 | CdS, 99.99%, 18” x 3.5” x 0.250” Sputtering Target, Bonded Cu BP/I |

| 244 | Cerac Aluminum Al Sputtering Target 5″ x .25″ |

| 245 | Cerac Chromium Silicide, CrSi2 Sputtering Target 5.94″ x .253″ |

| 246 | Cerac Indium-Tin Oxide 5 ” high Purity Sputtering Target |

| 247 | Cerac Specialty Inorganics Titanium Oxide TiO2 Sputtering Target |

| 248 | Cerac Titanium Sputter Target 99.999% Pure |

| 249 | Ceramic Back Sputter Shield |

| 250 | CHIYODA GREEN SPUTTER RESISTANT TUBING PN# TE-10AFG-20 |

| 251 | CHROMA ET535/50M SPUTTER/HARD COATED |

| 252 | Chrome sputtering target Chromium 5 inch round Varian MDP |

| 253 | Chromium Cr Sputtering Targets – 2.00″ Diameter, 0.250″ Thick – Kurt J. Lesker |

| 254 | Chromium sputter target, Cr 99.95% pure, 2″ diameter x 0.125″ thick |

| 255 | Chromium sputter target, Cr 99.95% pure, 2″ diameter x 0.25″ thick |

| 256 | CIGS – Sputtering Target – for solar cells |

| 257 | Cisco Kid Topper Top Water Buzz Sputter Bait Muskie Pike Bass Black Gold |

| 258 | Clunk & Sputter by Muerte Pan Alley (CD, 2014) |

| 259 | Co/Fe Sputtering Target: 90/10 At% 3N5 2” x 3mm Thick |

| 260 | Cobalt Chrome sputter target Co/Cr 83/17 at%, 99.95% pure, 3.0″ dia x 6mm thk |

| 261 | Cobalt Co Sputtering Targets – 2.00″ Diameter, 0.250″ Thick – Kurt J. Lesker |

| 262 | Cobalt Iron Aluminum sputter targe Co2/Fe/Al 99.95% 2″ diameter x 0.125″ thick |

| 263 | Cobalt Iron Boron sputter target (Co/Fe/B 6:2:2 at%, 99.9%) 1.50″ diam 2mm thick |

| 264 | Cobalt Iron Boron sputter target, Co/Fe/B 99.9% pure, 2″ diam x 3mm thk |

| 265 | Cobalt Iron Zirconium sputter target Co/Fe/Zr 60/25/15 at% 1.0″ diam x 0.1″ thk |

| 266 | Cobalt Manganese Silicon sputter target, Co2MnSi heusler alloy, 2″ dia x 3mm thk |

| 267 | Cobalt sputter target, 99.98% pure, 2″ diameter x 0.125″ thick |

| 268 | Cobalt sputter target, Co 99.95% pure, 1.00″ diameter x 0.045″ thick. |

| 269 | Cobalt Titanium sputter target Co/Ti 1:1 At% 99.95% 2“ diam x 1/4” thk |

| 270 | Cobalt with Iron, Boron & Silicon mixture- Sputtering Targets |

| 271 | Cobalt, Co – Sputtering Target |

| 272 | Cobalt/Iron sputter target, Co/Fe 50/50 weight% 99.95%, 2.00″ diam x 0.125″ thk |

| 273 | Cobalt/Iron/Boron sputter target Co/Fe/B 60/20/20 4″ diam x 0.079″ thick |

| 274 | Cobalt-Iron sputter target: Co/Fe 50/50 At% 3” x 0.08” Thick |

| 275 | Colored Sputtering Paint Shower Curtain Abstract Graffiti Bathroom Accessory Set |

| 276 | COMPUTATIONAL EXPLORATIONS IN MAGNETRON SPUTTERING By E. J. Mcinerney |

| 277 | Connecting Rod Bearing Kit Rotary VW Audi TDI 1,9l 1z AAZ AFN ASV AHF AVG 71-384… |

| 278 | Connecting Rod Bearing kolbenschmidt magnetrons BMW 2.5d 3.0d 24v m57d30 m51d25 … |

| 279 | Connecting Rod Bearing kolbenschmidt magnetrons VW t5 TRANSPORTER VAN 2,5l TDI A… |

| 280 | Connecting Rod Bearing magnetrons Audi VW 1,9l 2,0l 2,5l TDI ARL AVF ASZ Bottle … |

| 281 | Connecting Rod Bearing magnetrons Audi VW 1,9l 2,0l TDI BOTTLE BKD BLB BMM BL… |

| 282 | Connecting Rod Bearing magnetrons BMW e36 e39 e46 e60 525 530 TDS 6zyl. Diesel m… |

| 283 | Connecting Rod Bearing magnetrons GLYCO Mercedes Diesel C-Class E-Class |

| 284 | Connecting Rod Bearing magnetrons GLYCO Racing VW Audi Seat 1,8l 2,0l 16v Turbo … |

| 285 | Connecting Rod Bearing magnetrons GLYCO VW AUDI SEAT SKODA 1,2 1,4 1,9 TDI |

| 286 | Connecting Rod Bearing magnetrons kolbenschmidt VAG VW AUDI SEAT SKODA 1,9 2,0 T… |

| 287 | Connecting Rod Bearing magnetrons KS 0,25mm VW Audi Seat 1,8l 2,0l 16v Turbo 16v… |

| 288 | Connecting Rod Bearing magnetrons KS Racing Audi 5zyl. 2,2l s2 rs2 s4 s6 3b ABY … |

| 289 | Connecting Rod Bearing Set Sputtering VW Audi Tdi 1,9l 1Z Aaz AFN Asv Ahf AVG |

| 290 | Connecting Rod Bearing Sputtering GLYCO Mercedes Diesel C-Class |

| 291 | Connecting Rod Sputtering Audi VW 1,9l 2,0l 2,5l Tdi Arl Avf Asz Bkd Bmm 71-3930 |

| 292 | Connecting Rod Sputtering Audi VW 1,9l 2,0l Tdi Azv Bkd Blb Bmm Blt Axc Aws |

| 293 | Connecting Rod Sputtering KOLBENSCHMIDT BMW 4Zyl. Diesel M47D20 318d 320d E39 |

| 294 | Connecting Rod Sputtering KOLBENSCHMIDT VAG VW Audi Seat Skoda 1,9 2,0 Tdi |

| 295 | Connecting Rod Sputtering Ks Racing Audi 5Zyl. 2,2l S2 RS2 S4 S6 3B Aby Adu Aan |

| 296 | Connecting Rod Without Cam Sputtering VW Audi 1,2 1,4 1,9 Pd GLYCO 71-3904 Pair |

| 297 | Connecting Rod Without Cam Sputtering VW Audi 1,2 1,4 1,9 Pd GLYCO 71-3904 Set |

| 298 | CONROD BIGENG BEARINGS +0.5MM FOR MERCEDES BENZ M 276 DE35 SPUTTER REPLACEMENT |

| 299 | Copper Magnesium sputter target: Cu/Mg 98/2 wt%, 99.9% pure, 3″ dia x 6mm thk |

| 300 | Copper Nickel sputter target Cu/Ni 55/45 at% 99.99%, 1.00″ dia x 0.125″ thick |

| 301 | Copper Oxide Sputtering Target CuO 99.995″ Pure 2″ x .1875″ thick +Backing Plate |

| 302 | Copper Oxide, Cu2O – Sputtering Target |

| 303 | Copper SEM Sputter target: Cu 99.995% pure, 57mm diameter x 0.25mm thick |

| 304 | Copper sputter target Cu 99.997% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 305 | Copper, Cu – Sputtering Target |

| 306 | Copper/Gallium/Indium sputter target Cu/Ga/In (32.9/11.3/55.8 wt%) 1.5″ x 0.15″ |

| 307 | Copper/Manganese sputter target Cu/Mn 86.5/13.5 at% 1.5″ dia x 0.125″ thk |

| 308 | Copper/Nickel sputter target Cu/Ni 95/5 at% 99.99% 1 inch diam x 1/8 inch thk |

| 309 | Cover Food Splash Guard Microwave Anti-Sputtering with Steam Vents Magnetic |

| 310 | Cover Microwave Oven Food Cover Anti-Sputtering Heat Resistant Lid Household |

| 311 | CPI CPW2870B10-47 Power Supply 27-158946-00 36kW Sputtering 460V Input PARTS |

| 312 | Crystal Goose 7 Oz Wine Glasses on a Long Stem with Gold and Platinum Sputtering |

| 313 | Crystal Goose 7.1 Oz. Wine Glasses on a Long Stem with Gold Sputtering |

| 314 | Crystal Goose 7.1 Oz. Wine Glasses on a Long Stem with Gold Sputtering |

| 315 | Crystal Goose 8 Oz. Wine Glasses on a Long Stem with Gold Sputtering |

| 316 | Crystal Goose 8.11 Oz. Wine Glasses on a Long Stem with Gold Sputtering |

| 317 | Crystal Goose Two Glass Salad Bowls with Golden Sputtering |

| 318 | CTI-Cryogenics 8113008 On-Board FastRegen Control Sputtering Module |

| 319 | CTI-CYROGENICS ON-BD FAST REGEN CONTROL SPUTTERING 8129948G001 T13-D6 |

| 320 | CuGa – Sputtering Target – 99.99% purity |

| 321 | CUSTOM SPUTTERING SYSTEM W/ 5 SPUTTERING SOURCE & 1 EVAPORATION SOURCE |

| 322 | CVC Products 2800 Load Lock Dual Process Chamber Sputtering System with Handler |

| 323 | CVC Products Inc 2800 Sputter Shields Shutter Segments Cathode Stations Cleaned |

| 324 | CVC Products Vacuum Sputter Deposition System ENI RF Generators ACG 10 |

| 325 | CZTS & CZTS-Se- Copper-Zinc-Tin-Sulfur-Selenium Sputtering Targets |

| 326 | DC/RF Dual-Head High Vacuum 2″ Magnetron Plasma Sputtering Coater |

| 327 | Delta sputter target: Aluminum Al 99.999%,vacuum sealed, 200mm x 0.25″ |

| 328 | Denton Explorer 14 Sputter 2 Target, RF Generator, Matching Network, Turbo Pump |

| 329 | Denton vacuum desk carbon rod accessory 120volt |

| 330 | DENTON VACUUM DESK II Sputter Coater SEM Thin Film Deposition |

| 331 | Denton Vacuum Desk II Sputter Coater SEM Thin film Deposition *Parts/Repair* |

| 332 | Denton Vacuum DESK II Sputter Coater w/ Carbon Coater and Accessories |

| 333 | Denton Vacuum Desk-1 Cold Sputter Etch Unit |

| 334 | Denton Vacuum Desk-1 Cold Sputter Etch Unit Sputter coater and DCP-1 module |

| 335 | Denton Vacuum DV-502A High Vacuum sputtering parts transformer power supply |

| 336 | Denton Vacuum DV-502A High Vacuum sputtering parts valves |

| 337 | Denton Vacuum II Sputter / Sample Coater SEM Sample Prep |

| 338 | Desktop Magnetron sputtering PVD coating machine for fuel cell electrode sputter |

| 339 | DEUBLIN ROTARY UNION FOR SPUTTER ASSY, AMAT 0190-40352 SP0326 |

| 340 | Disney Pixar Cars Dan Haulin’ dinoco 400 #92 Sputter Stop cab |

| 341 | Disney Pixar Cars Lot Mack Hauler Truck 1:55 Diecast Model Car Toys Loose |

| 342 | Disney Pixar Cars McQueen 1:55 Diecast Movie Collect Car Toys Gift Boy Loose |

| 343 | Disney Pixar Cars McQueen 1:55 Diecast Movie Collect Car Toys Gift Boy Loose |

| 344 | Disney Pixar Cars Sputter Stop Kmart Exclusive Collector Days 1 Racer #92 |

| 345 | DISNEY PIXARCARS/PISTON CUP SPUTTER STOP NO.92 DIECAST VEHICLE ON CARD |

| 346 | Duniway Stockroom Corp. IPC-0062 Varian Sputter Ion Pump Control Unit PARTS |

| 347 | Duniway Stockroom GIP/25-TAP-M Sputter Ion Pump 10-4 torr – 10-11 torr vacuu |

| 348 | Dysprosium sputtering target Dy 99.9% 2″ diameter x 0.125″ thick: ACI ALLOYS |

| 349 | Early Arbogast Hawaiian Sputter Fuss Spinner Spoon Fishing Lure |

| 350 | Edwards S150B Sputter Coater T8840 Au/Pd 60mm *1 w/ Outlet Mist Filter MF20 |

| 351 | Edwards S150B Sputter Coater Works |

| 352 | EDWARDSS150B SPUTTER COATER WITH EDWARDS #2 VACUUM PUMP |

| 353 | Electromagnet for Nordiko Sputtering System |

| 354 | ENI 791521 DCG100 sputter module |

| 355 | ENI DCG-100A 10kW DC Sputtering Plasma Power Supply/Generator DCG2D-A031100021I |

| 356 | ENI OEM-50N-11601 13.56 MHz RF Plasma Generator Solid State for Sputter Chamber |

| 357 | Eratron PPS 8210 2KV RS MF 10kW DC Sputtering Plasma Power Supply with Castors |

| 358 | Eratron PPS 8210 RS MF 10KW DC Sputtering Plasma Power Supply |

| 359 | Eratron PPS 8210 RS MF High Power Sputtering Plasma Power Supply Output: 10KW DC |

| 360 | Erbium sputter target: Er 99.9% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 361 | Ernest F Fullam Vintage Sputter Coater 5 Torr Vacuum Gage |

| 362 | ESPI Metals Monel KND2240 Sputter Target |

| 363 | ESPI Metals Tin Zn AI Sputtering Target .375″x4.75″x14.875″ Purity 5N |

| 364 | ESPI Metals Tin Zn Sputtering Target .375″x4.75″x14.875″ Purity 5N |

| 365 | Europium sputter target Eu 99.9% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 366 | EVAC Chain Clamp Sanitary Pipe Ultra Low Vacuum Sputtering Deposition Chamber |

| 367 | FEI DUNIWAY Sputter Ion Pump Module 4022 198 24924 |

| 368 | FERROFLUIDICS ROTARY FEED THROUGH STAINLESS STEEL 52-110007 Sputtering Vacuum |

| 369 | FERROFLUIDICS ROTARY FEED THROUGH STAINLESS STEEL 7467 52-10007M Sputtering |

| 370 | FIL-TECH G71PT .709″ PYREX TWIN TUNGSTEN FILAMENTS MRC STYLE SPUTTERING G-71-PT |

| 371 | FIL-TECH G71PT .709″ PYREX, TWIN TUNGSTEN FILAMENTS, MRC STYLE, SPUTTERING – NIB |

| 372 | Fire Force Enen no Shouboutai Flare & Sputter T-shirt Japan Limited Cosplay |

| 373 | Fireball Beach Disney Pixar Cars #92 Sputter Stop Sheldon Shifter 1:55 Diecast |

| 374 | FISHING LURE ARBOGAST SPUTTER FUSS |

| 375 | FISHING LURE FRED ARBOGAST 3″ SPUTTER BUG RED HEAD |

| 376 | Fison Ins Polaron SC7640 Auto/Manual High Resolution Sputter Coater – Made in UK |

| 377 | Fisons Instruments Polaron SC7610 Sputter Coater w/ Vacuum Chamber |

| 378 | Fred Abrogast Hawaiian Wiggler lure lot (5) Sputter Fuss 3/8 oz 1/2 oz |

| 379 | Fred Arbogast Hawaiian Fishing Lure – Sputter Fuss |

| 380 | Fred Arbogast Sputter Fuss Hawaiian Fishing Lure |

| 381 | Fred Arbogast Sputter Fuss Hawaiian Fishing Lure |

| 382 | Ga2TeO3 – Sputtering Target – 99.99% purity |

| 383 | GAS DISTR. PLATE SPUTTER, AMAT 0020-09933 |

| 384 | Ga-ZnO – Sputtering Target – 99.99% purity |

| 385 | GENERIC SQT-0054 SPUTTER TABLE CHUCK OSR24544 SQT0054 |

| 386 | Generic Water Cooled Jacket for Sputtering / Vacuum Bell Jar Chambers |

| 387 | Germanium sputter target Ge 99.999% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 388 | Germanium Telluride (GeTe) Sputtering Target, 3″ D x 0.125″ thick 99.999% pure |

| 389 | Germanium-antimony-tellurium sputter target Ge2Sb2Te5 99.999% 1″ diam x 5mm thk |

| 390 | Glass For Viewport UHV Sputtering |

| 391 | Glow Discharge Processes : Sputtering and Plasma Etching, Hardcover by Chapma… |

| 392 | Glow Discharge Processes : Sputtering and Plasma Etching, Hardcover by Chapma… |

| 393 | GLOW DISCHARGE PROCESSES: SPUTTERING AND PLASMA ETCHING By Brian Chapman |

| 394 | Glow Discharge Processes: Sputtering and Plasma Etching by Brian Chapman |

| 395 | Glow Discharge Processes: Sputtering and Plasma Etching, Chapman, CHAPMA-, |

| 396 | GLYCO Connecting Rod Sputtering Volvo C70 S40 S60 S70 S80 V40 V60 V70 XC40 XC60 |

| 397 | Glyco Main Bearing Connecting Rod Sputtering Thrust Washers VW Audi 1,8T 20V S3 |

| 398 | GLYCO Main Bearings Rod Bearing magnetrons Thrust Washers VW Audi 1,8t 20v s3 ba… |

| 399 | Gold SEM Sputter target: Au 99.99% pure, 54mm diameter x 0.1mm thick |

| 400 | Gold SEM Sputter target: Au 99.99% pure, 57mm diameter x 0.1mm thick |

| 401 | Gold Target for MNT-JS1600 Plasma Sputtering Coater 50mm dia x 0.1mm (99.999%) |

| 402 | GREAT CONDITION-Mattel Disney Pixar Cars *SPUTTER STOP*-Never Opened-RARE |

| 403 | Great Prices and Quality from DeCluttr. 3m+ Feedbacks |

| 404 | Growth of High Permittivity Dielectrics by High Pressure Sputtering |

| 405 | GUND – SPUTTER THE BEAVER – #1553 – 9″ |

| 406 | Gund 1992 SPUTTER BEAVER w Bouquet & Tags 1553 |

| 407 | Gund 1992 Sputter Beaver White Pink Bouquet Stuffed Animal Plush Rare |

| 408 | H shaft connecting rod g60 steel connecting PG 1h + Connecting Rod Bearing magne… |

| 409 | Hafnium , Hf – Sputtering Target – 99.95% purity |

| 410 | Hafnium Oxide, HfO2 – Sputtering Target – 99.95% purity |

| 411 | Hafnium sputter target 99.99% pure Hf (<0.2% Zr) 2.00″ diam x 0.25″ thk |

| 412 | Hafnium sputter target, 99.9+% pure, 1.50″ diameter x 0.125″ thick |

| 413 | Hafnium/Silicon Hf/Si 1:1 at%, sputter target 4″ diam x 7mm thk, 99.9% pure |

| 414 | Handbook of Sputter Deposition and Technology HCDJ Wasa Hayakawa |

| 415 | Handbook of Sputter Deposition Technology : Fundamentals and Applications for… |

| 416 | Handbook of Sputter Deposition Technology : Fundamentals and Applications for… |

| 417 | Handbook of Sputter Deposition Technology: Fun.. 9781437734836 by Wasa, Kiyotaka |

| 418 | Handbook of Sputter Deposition Technology: Fund, Wasa.= |

| 419 | Handbook of Sputter Deposition Technology: Fundamentals and Applications for |

| 420 | HANDBOOK OF SPUTTER DEPOSITION TECHNOLOGY: PRINCIPLES, By Kiyotaka Wasa VG |

| 421 | Handbook of Sputter Deposition Technology: Principles, Technology and… |

| 422 | Hawaiian Sputter Fuss 2 1/2″ Long 5/8 0z. Yellow with multi color skirt |

| 423 | High Power Impulse Magnetron Sputtering : Fundamentals, Technologies, Challen… |

| 424 | High Power Impulse Magnetron Sputtering : Fundamentals, Technologies, Challen… |

| 425 | High Power Impulse Magnetron Sputtering: Fundam, Lundin, Daniel,, |

| 426 | High Purity 99.999% 5N Al Aluminum Sputtering Target Diameter 2” Thick 5mm |

| 427 | High Purity 99.999% 5N Al Aluminum Sputtering Target Diameter 70mm Thick 5mm |

| 428 | High Purity 99.999% 5N Al Aluminum Sputtering Target Diameter 70mm Thick 5mm |

| 429 | High Vacuum Deposition “Sputtering” Coating Machine |

| 430 | High Vacuum Heated Sensor Viewport / RGA Sputtering Analysis |

| 431 | Holmium sputter target Ho 99.9% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 432 | Honeywell 0190-20139/D 300mm Sputtering Target AMAT Applied Materials |

| 433 | Honeywell 037-0173-25 Sputtering Target 300mm |

| 434 | HONEYWELL 080796 Sputtering Target 5N5 TI 0437x11625x12555 BPM |

| 435 | HONEYWELL 084795 Sputtering Target 5N Al5Cu 7830x11640x13050 |

| 436 | Honeywell 090113 SPUTTERING TARGET 5N5 Al1Si.5Cu 12.555X11.625X1.600IN |

| 437 | Honeywell Sputtering Products 5N Ti Titanium) Target 20.625X17.478X1.000X0.500IN |

| 438 | Honeywell Sputtering Vectra Coil TSVCTISET-07935 OPENED READ |

| 439 | Honeywell target, M2000 sputtering, 59 Ti, .500X4.460X13.050 inches, PI000-04462 |

| 440 | Honeywell target, M2000 sputtering, 59.5Ti/.5CU, 4.460X11.64X13.050, PI000-05076 |

| 441 | Honeywell target, sputtering, M2000 49.5 Ti,.500X4.460X13.050inches, PI000-04462 |

| 442 | HONEYWELL TSENAL-MOX-06514 Sputtering Target 595AL5Cu 1910x11300x14495 |

| 443 | Honeywell TSQUALWDX-07821 Sputtering Target 59Al/1Cu 7.830×11.640×13.050″ |

| 444 | HOT WHEELS EDITIONS: #92 ’59 CADILLAC #98 ’03 SIDE SPUTTER |

| 445 | Huttinger 1841105-04 PCB TE 1714481 Plasma Sputtering System Trumpf |

| 446 | Huttinger 935416-16 Backplane Interface PCB Plasma Sputtering Trumpf |

| 447 | Huttinger Electronik TIG 30 DCplus Plasma Sputtering Controller Trumpf |

| 448 | Huttinger THE 478052 PCB Plasma Sputtering System Trumpf |

| 449 | Huttinger TIG 10/100 Sputtering Plasma Control Panel |

| 450 | HUTTINGER TIG 10/100P Sputtering Plasma Control Panel |

| 451 | Huttinger TIG 60 DC Plasma Sputtering Controller |

| 452 | Huttinger Trumph TIG 30 DCPLUS 30kW Plasma Sputtering Controller DC Plus kw |

| 453 | Huttinger Trumph TIG 30 DCPLUS 30kW Plasma Sputtering Controller DC Plus kw |

| 454 | IKC Chain Clamp Sanitary Pipe Ultra Low Vacuum Sputtering Deposition Chamber |

| 455 | Inconel 600 Sputter target: Ni/Cr/Fe 99.95% pure 2.00″ dia x 3mm thick |

| 456 | Indium Oxide (In2O3) Sputtering Targets- 99.99% Pure 3.00″ dia x 0.1875″ thick |

| 457 | Indium Tin Oxide (Kurt Lesker) sputtering target 4″ x .125″ thk 99.99% pure |

| 458 | Indium Tin Oxide sputter target: ITO 90/10 99.99% pure, 3″ x 0.1″ bonded to Cu |

| 459 | Indium Tin Oxide, ITO – Sputtering Target – 99.99% purity |

| 460 | Indium, In – Sputtering Target – 99.999% & 99.99% purity |

| 461 | Inficon SQM160-S-2-R Thin Film Deposition Monitor 2-Inputs, RS-232, 120/240VAC |

| 462 | InGaZnO4 – Bonded Target, – Sputtering Target – 99.99% purity |

| 463 | Innotec High Vacuum Batch Sputtering System Chamber |

| 464 | International Scientific Instrument PS-2 Coating unit Sputter Coater |

| 465 | Intevac Vacuum System Division TM-Gun Sputtering Source |

| 466 | Ion Implantation : Sputtering and Their Applications Hardcover P. |

| 467 | ION SPUTTER E1O1O HITACHI |

| 468 | Iron (Fe) Sputtering Targets – 2.00″ Diameter, 0.250″ Thick – Kurt J. Lesker |

| 469 | Iron SEM Sputter target: Fe 99.95% pure, 57mm diameter x 0.5mm thick |

| 470 | Iron SEM Sputter target: Fe 99.95% pure, 63mm diameter x 0.5mm thick |

| 471 | Iron Silicon Boron , FeSiB – Sputtering Target – 99.9% purity |

| 472 | Iron sputter target, 99.95% pure, 3″ diameter x 1mm thick |

| 473 | Iron sputtering target Fe 99.99% 2″ diameter x 0.0625″ thick: ACI ALLOYS |

| 474 | Iron, Fe – Sputtering Target |

| 475 | Jars Sputtering Anode Shields |

| 476 | JEGS – Selection, Value, Lifetime Support Since 1960… |

| 477 | JEOL FINE COAT Ion Sputter JFC 1100 BEAM W OMRON Miny Timer Type SYS |

| 478 | Johnson Matthey Sputtering Target mat’l: 49.5W/10Ti |

| 479 | Julanie Bonfire Stand Sheet Bonfire Sheet Sputtering Sheet Fire Authentic |

| 480 | Junron SP4 Green Sputtering Tube, For Spot Welder 2040 |

| 481 | Junron SP4-08 (GREEN) Sputtering Tube (Tube for Spot Welder) FNFP |

| 482 | Junron SP4-10 Sputtering Tube for Spot Welder |

| 483 | Junron SP4-10 Sputtering Tube for Spot Welder |

| 484 | Junron SP4-10 Sputtering Tube for Spot Welder |

| 485 | Junron SP4-10 Sputtering Tube for Spot Welder USIP |

| 486 | JX Nippon Mining & Metals FNx-000654B Sputtering Target 5N 17 17 |

| 487 | JX Nippon Mining Metals FNX-000544 F Sputtering Target 4N5 T7 17.508″x0.138″ DB |

| 488 | KEYED SHAFT SHAFT TRANSPORT BUFFER PN1001808 22.25 LONG 5/8 SPUTTER TOOL |

| 489 | KFMI 200MM SPTS SPUTTERING AL TARGET AL-0.5%CU (5N5) |

| 490 | KFMI 20CT17224 SPUTTERING AL TARGET 5N TI |

| 491 | KIA wheel ap for 2021 2022 KIA Sorento for 20-inch Sputtering Wheel Rim |

| 492 | Kimball / PHI Vacuum Electrical Feedthrough / Ion-Gun Sputtering 1.33″ CF Mini |

| 493 | KURT j LESKER 1 INCH OXIDE/TIN OXIDE SPUTTER TARGET |

| 494 | Kurt J Lesker Co. Zinc Oxide Sputtering Targets |

| 495 | Kurt J Lesker sputtering target Molybdenum (99.95%) 3″ diameter 0.1250″ THK |

| 496 | Kurt J Lesker sputtering target Ni-Cr target 80-20, 2″ – 0.125″ THK, 99.9% |

| 497 | Kurt J Lesker sputtering target Ni-Cr target 80-20, 3″ – 0.125″ THK, 99.9% |

| 498 | Kurt J Lesker sputtering target N-type doped Si (99.999%) 2″ – 0.250″ THK |

| 499 | Kurt J Lesker sputtering target Silicon Si undoped (99.999%) 2″ – 0.250″ THK |

| 500 | Kurt J. Lesker 108 Sputter |

| 501 | Kurt J. Lesker 750-005-G1 Sputtering Shutter Module Front Load Sensor |

| 502 | Kurt J. Lesker Cobalt Co Sputter Target 99.95% Pure, 4.00″ Dia. x 0.250″ Thick |

| 503 | Kurt J. Lesker Hafnium Hf Sputter Target 99.99% Pure, 3.0″ Dia. x 0.250″ Thick |

| 504 | Kurt J. Lesker Nickel Ni Sputter Target 99.99% Pure, 4.00″ Dia. x 0.250″ Thick |

| 505 | Kurt J. Lesker SILICON DIOXIDE (SiO2} Sputter Target, 3″ X .250 THICK, NOS |

| 506 | L.A. Girl Splatter Nail Lacquer Polish #355 Sputter |

| 507 | LADD MODEL# 30800 SPUTTER COATER |

| 508 | LADD MODEL# 30802 POWER SUPPLY FOR THE SPUTTER COATER |

| 509 | LAM / MRC Materials Research CORP. DC SPUTTER CONTROL PCB, P/N 880-71-000 REV G |

| 510 | Lam Research 15-135892-01 Sputtering Target Pedestal |

| 511 | LAM RESEARCH 715-026923-312A SPUTTERING TARGET HTR/BP ASSY |

| 512 | LAM RESEARCH ECHUCK328 SPUTTERING TARGET, 300MM (PARTS) 839-019090-328 |

| 513 | LAM RESEARCH ECHUCK328 SPUTTERING TARGET, 300MM 839-019090-328 |

| 514 | Lanthanum sputter target (99.9% La/TREM), 1.00″ dia x 0.125″ thick, in oil |

| 515 | Large pure silicon crystal ingot sputtering target polysilicon poly-silicon |

| 516 | Lead sputter target Pb 99.99% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 517 | Leybold / Balzers ZH620 Corona Sputtering System – Fully Operational |

| 518 | Leybold Coolpak 6000 Helium Compressor Removed From Pvd Sputtering Machine Q |

| 519 | LEYBOLD CORONA SPUTTERING SYSTEM ELEVATOR BOARD KHV-02 |

| 520 | LEYBOLD CORONA SPUTTERING SYSTEM ELEVATOR BOARD KHV-02 |

| 521 | LEYBOLD HAEREOUS Z660 DEPOSITION SPUTTERING |

| 522 | Leybold Heraeus z650 6″ Sputtering substrate holder |

| 523 | Leybold INFICON Sputter Discharge Sensor Head |

| 524 | Leybold WEA02 sputtering power supply |

| 525 | Leybold ZV6000 In Line Sputtering System / Dual Sided |

| 526 | Light Gold Sputter Window Tint Film VLT 70% Mirror Reflective Car Glass Anti-UV |

| 527 | Lithium Niobate, LiNbO3 – Sputtering Target – 99.99% purity |

| 528 | LITHIUM SPUTTERING, DEPOSITION AND EVAPORATION: CONTROLLED By Martin J. Neumann |

| 529 | LMO – LaMnO3 Sputtering Target – 99.9% purity |

| 530 | LSMO – La0.7Sr0.3MnO3 Sputtering Target – 99.9% purity |

| 531 | LTS Chemical inc sputtering target carbon (99.999%) 2″ diameter 0.1250″ AA-14 |

| 532 | Magnesium Fluoride, MgF2 – Sputtering Target – 99.99% purity |

| 533 | Magnesium sputter target Mg 99.95% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 534 | MAGNET GUARDMICROWAVE HOVER ANTI-SPUTTERING COVER |

| 535 | MAGNET MICROWAVE GUARD HOVER ANTI-SPUTTERING COVER |

| 536 | Magnetron Dual Head High Vacuum DC / RF Plasma Sputtering Coater CY-600-2HD |

| 537 | Magnetron Sputtering System for Multilayer Film Deposition with 3 S-Gun Cathodes |

| 538 | Main Bearing Big End GLYCO Sputtering Reinforced Audi VW 1.9 TDI AFN AHF ASV AVG |

| 539 | Main Bearings Rod Bearing Axial Bearing magnetrons Racing VW 1,6-2,0 reinforced … |

| 540 | Main Bearings Rod Bearing magnetrons VAG 1,8t 20v reinforced AGU AUM AJQ AEB ANB… |

| 541 | Manganese sputter target, 99.9% pure, 1.0″ diameter x 0.05″ thick |

| 542 | Manganese, Mn – Sputtering Target – 99.9% purity |

| 543 | Manganese/Tellurium sputter target Mn/Te (1:1 at%), 1.5″ diam x 0.15″ thk |

| 544 | Manganese-Germanium, Mn3Ge – Sputtering Target – 99.9% purity |

| 545 | Manganese-Tin, Mn3Sn- Sputtering Target – 99.9% purity |

| 546 | Material Research Corp MRC 603-III Sputtering Chamber 3-Targets on Side |

| 547 | Material Research Corporation Ni Mz Nickel Magnesium Sputtering Target |

| 548 | Material Research Corporation VP Vanadium Sputtering Target |

| 549 | Materials Research Corporation MRC RIE 61 Sputtering System. Ion Etcher |

| 550 | Materials Research Corporation XXB-100 electron beam sputtering system kit |

| 551 | Materion 101119284 Sputtering Target 16×6 Balzers |

| 552 | Materion 99.99% Tantalum Ta 12.98″ x.25″ Sputtering Target AMAT Centura |

| 553 | Materion Al/Cu 0.5% High Purity Sputtering Target, 12.98″ x 0.25″ |

| 554 | Materion Al/Cu 0.5% High Purity Sputtering Target, 12.98″ x 0.25″, |

| 555 | Materion NiFe 14W Sputter Target 10”Dia #US2227245. 553255-10 ZTH8000 NOS |

| 556 | Materion Silicon SI Sputter Target 0001703733 314259 2.9921″ DIA X 0.1969″ |

| 557 | Materion Sputter Target # US1637146. |

| 558 | Materion Titanium Sputtering Target 12.73″ x 1.9″ Purity 99% |

| 559 | MeiVac 2460 Chamber Lid Control Module Vacuum Sputter System |

| 560 | Mill Lane Engineering 4 source load locked with plasma clean sputter system |

| 561 | Mint Condition LEYBOLD CORONA SPUTTERING SYSTEM ELEVATOR BOARD KHV-02 |

| 562 | MKS ENI DCG-100 DC sputtering power supply. Master |

| 563 | Moly Chrome sputter target: Mo/Cr 85:15 at%, 2.00″ dia x 0.25″ thick, 99.9% pure |

| 564 | Molybdenum (Mo) sputter target, 99.99% pure 1.7″ diam x 0.125″ thick |

| 565 | Molybdenum Chrome sputter target MoCr 95/5 99.95% 3″ diameter x 0.25″ thick |

| 566 | Molybdenum di sulfide, MoS2 – Sputtering Target – 99.5% purity |

| 567 | Molybdenum silicide-Sputter Target – 99.5% |

| 568 | Molybdenum sputter target, Mo 99.95% 2″ diameter x 0.25″ thick |

| 569 | Molybdenum sputter target, Mo 99.95% pure, 1.5″ diameter x 0.25″ thick |

| 570 | Molybdenum trioxide, MoO3 – Sputtering Target – 99.99% purity |

| 571 | Molybdenum, Mo – Sputtering Target |

| 572 | MRC 20-555B-NB000-9000 NIOBIUM 99.8 RMX12 ASSY Sputtering Target Plate |

| 573 | MRC 5″ Stainless Steel ZINC Backing Plate, 808-03-005 Sputtering Target |

| 574 | MRC 500354-00 Belt, Timing .5W X15 Long Sputtering Tool |

| 575 | MRC 500665-00 Pin, Arm First, Sputtering Tool |

| 576 | MRC 500670-00 Bearing, Thrust Sputtering Tool |

| 577 | MRC 500676-00 Bearing Sputtering Tool |

| 578 | MRC 500681-00 Thermostat, Tempswitch Sputtering Tool |

| 579 | MRC 500691-00 Standoff, Vented Sputtering Tool |

| 580 | MRC 500737-00 Bearing, Arm (Elbow) Sputtering Tool |

| 581 | MRC 6.5 In Magnetron Sputter Cathode |

| 582 | MRC 808-88-100 NI/FE19% Mounted 6″ x 0.25″ TH Sputtering Target |

| 583 | MRC 828-04-200 VP Nickel 15″ x 4.75″ x 0.25″ Sputtering Target |

| 584 | MRC A114265 Quad 1000 RF Deck Sputter Power Supply 3500 VDC Eimac SK-4063-500Z |

| 585 | MRC Materials Research A115015 Sputtering System Remote Stand Rev. C |

| 586 | MRC Materials Research A120024 Sputtering System Remote Stand Eclipse Star |

| 587 | MSDS Materion Cr Chromium 99.95% 4″ Dia x 0.25″ Sputtering Target Plate |

| 588 | MTI Corporation GSL-1100X-SPC-12 Compact Plasma Sputtering Coater |

| 589 | MURRAY CLUTCHBURN #92 SPUTTER STOP DISNEY PIXAR CARS 3 2016 SCALE 1:55 |

| 590 | Muto Technology MT-49963 Sputter # 2/3 Cu Shield Kit 6″ 150mm Copper |

| 591 | MXL 910 Microphone MIC w/ Gold-sputter 6-micron diaphragm |

| 592 | Neodymium sputtering target Nd 99.9% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 593 | Nickel Moly Ni85Mo15 wt% sputter target- 1″ diameter x 0.25″ thick, 99.95% pure |

| 594 | Nickel Ni sputtering target- 99.99% pure 3.00″ diameter x 0.25″ thick |

| 595 | Nickel Oxide (NiO) Sputtering Target- 99.98% Pure 3.00″ dia x 0.125″ thick |

| 596 | Nickel SEM Sputter target: Ni 99% pure, 54mm diameter x 0.05mm thick |

| 597 | Nickel SEM Sputter target: Ni 99% pure, 57mm diameter x 0.025mm thick |

| 598 | Nickel SEM Sputtering target: Ni 99.9% pure, 57mm diameter x 0.25mm thick |

| 599 | Nickel sputtering target- 99.99% pure 2.00″ diameter x 0.125″ thick |

| 600 | Nickel sputtering target, 99.9% pure Ni, 3.00″ diameter x 0.125″ thick |

| 601 | Nickel sputtering target: 99.98% pure Ni, 1.00″ diameter x 0.25″ thick |

| 602 | Nickel Sulfide, Ni3S2- Sputtering Target – 99.5% purity |

| 603 | Nickel Titanium Ni/Ti 1:1 at% sputtering target: 2.0″ dia x 0.17″thk 99.99% pure |

| 604 | Nickel Vanadium(93:7 wt%), Ni-V – Sputtering Target – 99.95% purity |

| 605 | Nickel, Ni – Sputtering Target – 99.99%, 99.999% purity |

| 606 | Nickel-titanium sputter target: Ni/Ti 50/50 at%, 3″ dia x 1/4″ thk |

| 607 | Niobium 99.95% pure SEM sputter target, 57mm diameter x 0.5mm thick |

| 608 | Niobium Nb sputtering target: 3.99″ dia x 0.25″ thick 99.95% pure |

| 609 | Niobium Selenide, NbSe – Sputtering Target – 99.9% purity |

| 610 | Niobium sputtering target Nb 99.99% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 611 | Niobium Sputtering target: Nb 99.95% pure, 63mm diameter x 0.2mm thick |

| 612 | Niobium Titanium Nb/Ti 80/20 wt% sputter target: 3″ dia x 5mm thk 99.95% pure |

| 613 | Niobium, Nb – Sputtering Target – 99.95% purity |

| 614 | Nitoms Colo body floor Clean SC sputtering and expire adjustable length [26cm ~ |

| 615 | No Name Copper Unbranded Sputter Sputtering Target 4FC5297 001 18MM ID |

| 616 | NORDIKO A08759 HEATER ASSEMBLY ~ 9606 METAL FILM PVD SPUTTERING COATING |

| 617 | Nordiko D00019 Platform Low Tension DC Power Supply 9550 PVD Sputtering |

| 618 | Nordiko D00021 Platform Low Tension DC Power Supply 9550 PVD Sputtering |

| 619 | Nordiko MAG AMP Rotating Magnet Amplifier Controller 9550 PVD Sputtering |

| 620 | Nordiko RF Viewport Shield CF160 Sputtering System |

| 621 | Nordiko RF Viewport Shield Sputtering System |

| 622 | Nordiko RF Viewport Shield Sputtering System @ 4″x4″ |

| 623 | Nordiko Rotating Magnet Drive Controller Copley 423 9550 PVD Sputtering |

| 624 | Nordiko Rotating Magnet Power Supply Copley TR239-45 9550 PVD Sputtering |

| 625 | Nordiko Sputtering System Fast Shutter Actuator W/ Spinea Gear NTS00357 |

| 626 | Nordiko Sputtering System PC Board Controller N600599EE |

| 627 | Novellus 00-672232-00 Turnbuckle Assy. For 3000 Series Sputter System |

| 628 | NOVELLUS 04-710723-05 REV M RF MAGNETRON 17-116776-00 RADIO FREQUENCY SPUTTERING |

| 629 | NRC Sputtering Chamber with Varian SD-700 Vacuum Pump – Cracked Jar |

| 630 | Oerlikon Sputtering System Motor Drive W/cooling Plate 10068415 |

| 631 | OMP MAESM1AB Sputter Unit Interface MAE-SM1AB Control Board MAE SM1AB |

| 632 | OMP MAESM40A SPUTTER UNIT HV |

| 633 | OMP Maesm40A Sputter Unit HV with Maesm60A Sputter IGBT |

| 634 | Oryx Anelva Disposable Sputter Shield 215mm ANL62828 |

| 635 | ORYX Sn Zn AI Sputtering Target .375″x4.75″x14.875″ |

| 636 | ORYX Sn Zn Sputtering Target .375″x4.75″x14.875″ 65SN 35Zn nwt% |

| 637 | Osmium sputter target Os 99.9% 2″ diameter x 0.25″ thick: ACI ALLOYS, about 275g |

| 638 | OXFORD PLASMALAB SYSTEM 400 SPUTTER COATER |

| 639 | P5000 SPUTTER Process Kit. AMAT, |

| 640 | Palladium SEM Sputter target: Pd 99.99% pure, 57mm diameter x 0.1mm thick |

| 641 | Palladium sputtering target Pd 99.95% 2″ diameter x 1mm thick: ACI ALLOYS |

| 642 | Pella Pelco SC-7 Auto Sputter Coater Sputtering System (Ted Pella 7002) |

| 643 | Perkin Elmer 4400 Sputtering System |

| 644 | Perkin Elmer 4450 Sputtering PVD Tool Delta Target, Cryo Compressor, Vacuum pump |

| 645 | Perkin-Elmer 221-659-200 Pumpdown Control Gauge For 4450 Sputter System |

| 646 | Perkin-Elmer 4400 221-201-100 Auto Pumpdown Control Gauge Sputter System |

| 647 | Perkin-Elmer Sputtering system model 3140 |

| 648 | PERKIN-ELMER ULTEK AUTO PUMPDOWN CONTROL GAUGE SPUTTER |

| 649 | Permalloy, Ni:Fe – Sputtering Target – 99.95% purity |

| 650 | Pfeiffer Vacuum Classic 590 Evaporator PVD Sputtering system |

| 651 | Planar Magnetron Sputtering Magnet Sierra Applied Sciences Patent #5,262,026. |

| 652 | Planar Magnetron Sputtering Magnet Sierra Applied Sciences Patent #5,262,026. |

| 653 | Planar Magnetron Sputtering Magnet Sierra Applied Sciences Patent #5,262,028 |

| 654 | Plasma Sputtering Coater with Vacuum Pump Gold Target |

| 655 | Plasma Sputtering Coater with Vacuum Pump, Gold Target |

| 656 | plasmaterials lithium cobalt oxide sputter target LiCoO2 vacuum deposition |

| 657 | Plasmaterials Vanadium Sputtering Target 13.7″ x 0.4″ Purity 99.5% |

| 658 | Plasmionique FLR 300-TT Plasma Sputter Coater Etching |

| 659 | Platinum SEM sputter target Pt 99.99% 63mm diameter x 0.3mm thick: ACI ALLOYS |

| 660 | Platinum SEM Sputter target: Pt 99.99% pure, 57mm diameter x 0.1mm thick |

| 661 | PMN-PT – Sputtering Target – 99.9% purity |

| 662 | POLARON E6300 SPUTTER COATER SPUTTERING SYSTEM FISONS COATING CONTROL PANEL |

| 663 | POLARON E6300 SPUTTER COATER SPUTTERING SYSTEM FISONS POWER CONTROL PANEL |

| 664 | POLARON E6300 SPUTTER COATER SPUTTERING SYSTEM FISONS VACUUM CONTROL PANEL |

| 665 | Polaron Range Sputter Coater |

| 666 | Polaron Range Sputter Coater |

| 667 | Praxair Ceramics Ba-Sr-Ti-Zr 8″ Sputtering Target soldered to Backing Plate 413 |

| 668 | Praxair Ceramics Sputtering Target Ba-Sr-Ti-Nb Oxide 99.9% 8″x 0.25″ (3163) |

| 669 | Praxair Ceramics Sputtering Target Ba-Sr-Ti-Y Oxide 99.99% 10″x0.25″ (3131) |

| 670 | PRAXAIR MRC 20-555B-MO000-300 MO MOLYBDENUM Sputtering Target Plate |

| 671 | PRAXAIR MRC MRCGTI0009678 TI TITANIUM Sputtering Target Plate |

| 672 | Praxair Sputtering Target Barium Strontium Ti-Y Niobium Oxide 99.99% |

| 673 | Pulsed and Pulsed Bias Sputtering: Principles a, Barnat, Edward,, |

| 674 | Pulsed and Pulsed Bias Sputtering: Principles and Applications |

| 675 | Pulsed And Pulsed Bias Sputtering: Principles And Applications |

| 676 | Pulsed And Pulsed Bias Sputtering: Principles And Applications |

| 677 | Pulsed And Pulsed Bias Sputtering: Principles And Applications Barnat Lu |

| 678 | Pulsed and Pulsed Bias Sputtering: Principles and Applications, Barnat, Lu-, |

| 679 | PURE TECH Chromium/Titanium Cr/Ti 20%, at% 44093.0/01/1 Sputtering Target |

| 680 | Pure Tech Sputtering Target – Al/Cu 4%, wt% – 2″ Dia – 1/4″ Thick – 99.99% Pure |

| 681 | Pure Tech Sputtering Target – Zinc – 2″ Dia – 1/8″ Thick – 99.995% Pure |

| 682 | PVD for Microelectronics: Sputter Desposition to Semiconductor Manufacturing: |

| 683 | Quantum Cleaned 4″ Glass For Viewport UHV Sputtering |

| 684 | Quartz sputtering target: SiO2 99.995%, 3.00″ diameter x 0.25″ thick |

| 685 | quartz substrate heaters for vacuum evaporator or sputtering systems |

| 686 | QUORUM EMITECH K550 FULLY AUTOMATIC SPUTTER COATER SPUTTERING SYSTEM |

| 687 | Quorum Sputter Coater Q150R-ES with Edwards RV5 Pump silver Target |

| 688 | Quorum Tech/Emitech K250 Sputter Coater System Controller |

| 689 | Quorum/Polaron SC7640 Auto/Manual High Resolution Sputter Coater |

| 690 | Race Motorsport rotary connecting rod 5zyl. s2 rs2 s4 s6 2,2 ADU 3b ADY RR aan |

| 691 | Race Motorsport Sputtering Big End Bearings 5Zyl. S2 RS2 S4 S6 2,2 Adu 3B Ady RR |

| 692 | RARE Disney Pixar The World of Cars Sputter Stop + Gasprin |

| 693 | RARE MISPRINT Disney Store CARS 2006 Doc Hudson Talking Car Sputtering Action |

| 694 | Rare Varian Sputtering Power Supply Kilowatt Meter Type VPW2871B2 |

| 695 | Reactive Sputter Deposition by Diederik Depla |

| 696 | Reinforced BIG END BEARINGS Sputtering GLYCO VW 2,5L TDI LT28 T4 Transporter |

| 697 | Reinforced Connecting Rod Sputtering VAG 1,8T 20V Agu Aum Ajq Aeb ANB App Bam |

| 698 | Reinforced Motorsport rotary connecting Rod Bearings Glyco VW 16v g60 1,8t 2,0 T… |

| 699 | Reinforced Motorsport Sputtering Connecting Rod GLYCO VW 16V G60 1,8T 2,0 Turbo |

| 700 | Reinforced Rod Bearings magnetrons GLYCO VW 2,5l TDI lt28 t4 Transporter AXG ACV… |

| 701 | Reinforced Rod Bearings magnetrons VAG 1,8t 20v AGU AUM AJQ AEB ANB APP BAM BFV … |

| 702 | Research DYNAMO! 2″ RF sputtering thin film deposition system coater + 9 TARGETS |

| 703 | Rhenium sputtering target Re 99.95% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 704 | Riber Vacuum Pressure Gauge – Sputtering |

| 705 | RON HAWKINS (90’S) – SPIT SPUTTER SPARKLE CD |

| 706 | Rotary Connecting Rod & Main Bearing VW AUDI 16v g60 1,8l 1,8t 20v 2,0 PG 2e AEB |

| 707 | Rotary Connecting Rod & MAIN BEARINGS & THRUST WASHERS 16V G60 1,8T 2,0 PG 2E AE… |

| 708 | Rotary Connecting Rod Bearing kolbenschmidt BMW 4 Cylinder 2,0 2,0 D n47d20 116d… |

| 709 | Rotary Connecting Rod Bearing KS BMW 6 Cyl. N57D30 B57D30 Alpina 3er 5er X3 X4 X… |

| 710 | Rotary Connecting Rod Bearings Glyco BMW 4 Cyl. 6 Cyl. n47d20 n57d30 |

| 711 | Rotary Connecting Rod Bearings Glyco BMW 4 Cylinder 2,0 D n47d20 116d 118d 120d … |

| 712 | Round 4” Sputtering Target Titanium Aluminum |

| 713 | Ruthenium (RU) Target Sputter 224μm |

| 714 | Ruthenium 99.9% pure SEM sputter target, 57mm diameter x 0.75mm thick |

| 715 | Ruthenium sputtering target Ru 99.95% 2″ diameter x 0.125″ thick: ACI ALLOYS |

| 716 | Ruthenium, Ru – Sputtering Target -99.95% |

| 717 | Ruthenium, Ru – Sputtering Target -99.95% |

| 718 | Samarium sputtering target, 99.9%, 2″ diameter x 0.25″ thick |

| 719 | Scandium sputter target: 4.00″ diameter x 0.125″ thick, 99.995% pure |

| 720 | Scandium sputtering target Sc 99.99% 2″ diameter x 0.125″ thick: ACI ALLOYS |

| 721 | Selenium sputtering target Se 99.999% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 722 | SEM Gold Au Sputtering Target: 99.99% Pure 57mm D x 0.1mm Thick Cutomizable |

| 723 | SEM Silver Ag Sputtering Target: 99.99% Pure,57mm D x 0.1mm Thick Customizab |

| 724 | SEM Sputter Coater PS3 Unit, Polaron PS100 Power Supply & Gold Carbon Applicator |

| 725 | Sencera In-line Sputter 6 target large panel DC power supply vacuum & Turbo pump |

| 726 | SHIBAURA Sputtering Machine Power Supply STELLA 200 |

| 727 | Si sputtering target Silicon pure undoped (99.999%) 2″ diameter x 0.070″ thick |

| 728 | Silicon (N & P Types) Sputtering Targets, 3″ D x 0.125″ thick, 99.999% pure |

| 729 | Silicon alloy sputter target Si: 4.75 x 22.0″ x 0.25″ |

| 730 | Silicon and carbon Sputtering Target, 3″ D x 0.250″ thick, |

| 731 | Silicon B-doped, 5N 18” x 3.5” x 0.250” Sputtering Target, Bonded Cu BP/I |

| 732 | Silicon Carbide N Type Sputtering Target, 3″ D x 0.125″ thick, 99.9% pure |

| 733 | Silicon Carbide N Type Sputtering Target, 3″ D x 0.25″ thick, 99.9% pure |

| 734 | Silicon Carbide N Type Sputtering Target, 3″ D x 0.375″ thick, 99.9% pure |

| 735 | Silicon Carbide Sputtering Target, 3″ D x 0.125″ thick, 99.5% |

| 736 | Silicon Carbide Sputtering Target, 3″ D x 0.125″ thick, 99.9% pure |

| 737 | Silicon Carbide Sputtering Target, 3″ D x 0.125″ thick, 99.9% pure |

| 738 | Silicon Carbide Sputtering Target, 3″ D x 0.25″ thick, |

| 739 | Silicon Carbide Sputtering Target, 3″ D x 0.25″ thick, |

| 740 | Silicon Carbide Sputtering Target, 3″ D x 0.255″ thick, |

| 741 | Silicon Carbide Sputtering Target, N 3″ D x 0.125″ thick, 99.5%-slightly chipped |

| 742 | Silicon Carbide, SiC, sputtering target, 3″ D x 0.250″ thick, N-Type |

| 743 | Silicon dioxide, SiO2 – Sputtering Target – 99.99% purity |

| 744 | Silicon Germanium Sputtering Target, 3.00″ D x 0.25″ thick, 99.999% pure |

| 745 | Silicon Germanium, SiGe sputtering targets, 3″ D x 0.125″ thick, 99.999% pure |

| 746 | Silicon Indium Zinc Oxide sputter target 99.9% 3″ dia x 0.2″ thick, bonded to Cu |

| 747 | Silicon Nitride Si3N4 sputtering target 99.5% 3″ diameter x 0.125″ thick |

| 748 | Silicon Nitride, Si3N4 – Sputtering Target |

| 749 | Silicon Nitride, Si3N4 sputtering target, 3″ D x 0.125″ thick, 99.9% pure |

| 750 | Silicon sputtering target Si 99.9999% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 751 | Silicon Sputtering Target, 2.950″ D x 0.125″ thick, 99.999% pure |

| 752 | Silicon Sputtering Target, 3″ D x 0.125″ thick, 99.999% pure |

| 753 | Silicon Sputtering Target, 3.00″ D x 0.25″ thick, 99.999% pure |

| 754 | Silicon, Si – Sputtering Target – 99.999% purity |

| 755 | Silve Target for MNT-JS1600 Plasma Sputtering Coater 50mm dia x 0.5mm (99.99%) |

| 756 | Silver SEM Sputter target: Ag 99.99% pure, 54mm diameter x 0.1mm thick |

| 757 | Silver SEM Sputter target: Ag 99.99% pure, 57mm diameter x 0.1mm thick |

| 758 | Silver SEM Sputter target: Ag 99.99% pure, 57mm diameter x 0.25mm thick |

| 759 | Silver, Ag – Sputtering Target – 99.999% & 99.99% purity |

| 760 | Singulus S-III / Skyline sputter cathode, PVD coating tool, 163 mm diam. target |

| 761 | Slotted Glass Chamber for Ladd Sputter Coater – 3.8″ Long x 2.9″ Diameter #4210 |

| 762 | Small Aluminum Vacuum Chamber 18 by 10″ overall “Sputter Target”? Assembly |

| 763 | small desk type magnetron sputtering apparatus with controllable sputtering powe |

| 764 | SMC SPUTTER CHAMBER MTS32-P2168-40 |

| 765 | Solar Applied Materials Aluminum Al Sputtering Targets 171mm X 15mm, 850 Grams |

| 766 | Solar Module inline sputteranlage Leybold OPTICS H3200 Coater sputtering |

| 767 | Solyndra 0141-30380, DC Gen 3-Target Intcon Cable 28FT for Sputtering System |

| 768 | Solyndra 0141-30549, 2 Splitter Cables to 4 each for PWR & TC Dist Sputtering HT |

| 769 | Spark Plug f3cs Bosch Motorsport 1,8t 16v Turbo s3 c20let s2 rs2 s4 vr6 Turbo |

| 770 | SPI Sputtering Coater Model 12121 |

| 771 | SPI Sputtering Coater Model 12121 Sputter |

| 772 | SPI Supplies Module Controls Vacuum Base 11425 Sputter and Carbon Coater |

| 773 | Splatter Guard Microwave Hover Anti-Sputtering Vent Cover clear with magnets |

| 774 | Spring Handle Welding Chipping Hammer Weld Slag Buster Sputter |

| 775 | Sputter Cathode for Unaxis Twister CD Metalizer |

| 776 | Sputter Chamber 12″ Target, PVD, Wafer Processing, 943-2, 302401, Backing Plate |

| 777 | Sputter Chamber 12″ Target, PVD, Wafer Processing, 943-2, 302401, Backing Plate |

| 778 | SPUTTER COATER MOTORIZED ROTATIONAL STAGE |

| 779 | SPUTTER PIPE |

| 780 | Sputter Stop No. 92 Piston Cup 2013 Disney Pixar Cars 2 diecast Mattel VHTF! |

| 781 | SPUTTER STOP NO. 92, 1/55 SCALE, DISNEY PIXAR CARS, PISTON CUP |

| 782 | SPUTTER STOP No.92 – PISTON CUP – 15 of 18 – DISNEY PIXAR CARS |

| 783 | SPUTTER TABLE CHUCK SQT-0054 OSR24544 |

| 784 | Sputter Target Aluminum for Singulus III Focus Cathode 3231001 |

| 785 | Sputter target: Chromium/Nickel Cr/Ni 60/40 wt% 6.00″ dia x 0.25″ thk, 99.99% |

| 786 | Sputter target: Si3N4 99.5% pure, 1.0″ diameter x 0.125″ thick, bonded to copper |

| 787 | Sputter Vacuum Chamber Assembly 14″ 300mm with Industrial Devices CVC001 Drive |

| 788 | Sputtering Big End Bearings KOLBENSCHMIDT BMW 4 Cylinder 2,0 D N47D20 116D |

| 789 | Sputtering Big End Bearings Ks BMW 6 Cylinder N57D30 B57D30 Alpina 3er 5er X3 X4 |

| 790 | SPUTTERING BY PARTICLE BOMBARDMENT I: PHYSICAL SPUTTERING By R. Behrisch |

| 791 | Sputtering by Particle Bombardment I: Physical Sputtering of Single-Element… |

| 792 | Sputtering by Particle Bombardment Ii: Sputtering of Alloys and Compounds, Elect |

| 793 | Sputtering By Particle Bombardment: Experiments And Computer Calculations F… |

| 794 | Sputtering by Particle Bombardment: Experiments and Computer Calculations f… |

| 795 | SPUTTERING EVAPORATION TARGET Co Cr Ta TANTALUM METAL |

| 796 | Sputtering Materials for VLSI and Thin Film Devices |

| 797 | Sputtering of Ammonite Spitoniceras with Pyrite and Cretaceous Symbircite 130mln |

| 798 | Sputtering Sheet Bonfire Sheet Heat Flameproof Bonfire Table La Authentic |

| 799 | sputtering target Molybdenum (Mo) 99.9% 2″ diameter 0.02″ AA-16 |

| 800 | sputtering target NiSi 2/1 at% 2″x.110 |

| 801 | Sputtering Target Silicon Dioxide (SiO2) Diameter:3 inch Thick:0.5 inch:4 pcs |

| 802 | sputtering target Zn/Cu (50:50 at% 99.99%) 2″ diameter 0.1250″ AA-10 |

| 803 | sputtering target ZnO/Cu2O (50:50 MOL% 99.95%) 2″ diameter 0.1250″ AA-11 |

| 804 | sputtering target, Al 2″x.250″ |

| 805 | Sputtering Target, AlCu 99/1 2″x.250″ |

| 806 | Sputtering Target, AlMn 50/50 at% 2″x.125″ |

| 807 | Sputtering Target, AlNd 97/3 wt% 2″x.250″ |

| 808 | sputtering target, AlNd 98/2 wt% 2″x.250″ |

| 809 | Sputtering Target, AlNi 22.3/77.7 wt% 2″x.200″ |

| 810 | Sputtering Target, AlTi 96.5/3.5 wt% 2″x.125″ |

| 811 | Sputtering Target, Aluminum (Al) 2″x.250″ |

| 812 | sputtering target, BiIn 10/1 at% 2″x.150″ |

| 813 | Sputtering Target, BiIn 4/1 at% 2″x5mm |

| 814 | sputtering target, Chromium (Cr) 2″x.250″ |

| 815 | Sputtering Target, CoAl 1/1 at% 2″x.250″ |

| 816 | Sputtering Target, CoFe 80/20 wt% 2″x.040″ |

| 817 | Sputtering Target, CoFe 90/10 at% 2″x3mm |

| 818 | sputtering target, CoFe 95/5 at% 2″x.145″ |

| 819 | Sputtering Target, CoFe 95/5 at% 2″x.145″ |

| 820 | Sputtering Target, CoFeAl 2/1/1 2″x.125″ |

| 821 | Sputtering Target, CoFeB 21/51/28 at% 2″x.125″ |

| 822 | Sputtering Target, CoGd 95/5 wt% 2″x.175″ |

| 823 | Sputtering Target, CoNi 20/80 at% 2″x.120″ |

| 824 | Sputtering Target, CoNi 20/80 at% 2″x.150″ |

| 825 | Sputtering Target, CoNi 55/45 2″x.240″ |

| 826 | sputtering target, CoTi 1/1 at% 2″x.250″ |

| 827 | sputtering target, CoTi 1/1 at% 2″x.250″ |

| 828 | sputtering target, Cr 2″x.250″ |

| 829 | sputtering target, FeAl 96.5/3.5 2″x.090 |

| 830 | Sputtering Target, FeAl 96.5/3.5 2″x.090″ |

| 831 | Sputtering Target, FeAl 96/4 at% 2″x.090″ |

| 832 | Sputtering Target, FeAl 96/4 at% 2″x.090″ |

| 833 | Sputtering Target, FeAl 97.5/2.5 2″x.090″ |

| 834 | sputtering target, FeB 7/3 at% 2″x.125″ |

| 835 | Sputtering Target, FeCo 65/35 at% 2″x.235″ |

| 836 | Sputtering Target, FeMo 85/15 at% 2″x.120″ |

| 837 | sputtering target, FeTb 30/70 wt% 2″x.120″ |

| 838 | sputtering target, GeTe 1/1 at% 2″x.125″ |

| 839 | sputtering target, MnGa 50/50 at% 2″x.125″ |

| 840 | Sputtering Target, MoCr 85/15 at% 2″x.250″ |

| 841 | Sputtering Target, NbTi 70/30 wt% 2″x.060″ |

| 842 | Sputtering Target, Ni 2″x.125″ |

| 843 | sputtering target, Ni/Ti 10/90 wt% 2″x.250″ |

| 844 | sputtering target, NiFe 50/50 wt% 2″x.228″ |

| 845 | Sputtering Target, NiFe 50/50 wt% 2″x.228″ |

| 846 | Sputtering Target, NiFe 7/3 at% 2″x.125″ |

| 847 | sputtering target, NiFe 79/21 at% 2″x.125″ |

| 848 | Sputtering Target, NiFe 79/21 at% 2″x.125″ |

| 849 | sputtering target, NiSi 2/1 at% 2″x.110″ |

| 850 | sputtering target, NiTi 10/90 wt% 2″x.250 |

| 851 | Sputtering Target, NiTi 10/90 wt% 2″x.250″ |

| 852 | sputtering target, NiTi 25/75 wt% 2″x.250″ |

| 853 | sputtering target, NiTi 25/75 wt% 2″x.250″ |

| 854 | Sputtering target, NiTi 50/50 at% 2″x.170″ |

| 855 | sputtering target, NiTi 50/50 at% 2″x.170″ |

| 856 | Sputtering Target, NiTi 50/50 at% 2″x.170″ |

| 857 | Sputtering target, Yttrium 2″x.063″ |

| 858 | sputtering target, ZnAl 98/2 wt% 2″x.250″ |

| 859 | STD 77218600 BMW M57 D30/25 M51 D25 M21 D25/24 SPUTTER big end con rod bearing |

| 860 | Steag FLT Unijet metalizer lid for sputter metalizer |

| 861 | Steel Connecting Rod GENUINE k1 + Connecting Rod Range 1,8t 20v s3 BAM AMK 144mm… |

| 862 | Steem-Up 3″ Steam Iron Cleaner Cleans Clogged Iron Stop Sputtering Lot 2 |

| 863 | Strontium Ruthenate, SrRuO3 – Sputtering Target |

| 864 | Strontium Ruthenium Titanate – Sputtering Target – 99.9% purity |

| 865 | Sun Surface Technology Sputtering Platform 18 inch 15-293699-00 |

| 866 | Ta2O5 99.9% pure sputter target, 90mm diameter x 12.5mm thick |

| 867 | Tantalum 99.95% sputter target, 60mm diam 5mm thick with step Sputtering target |

| 868 | Tantalum Pentoxide (Ta2O5) 99.9% Pure Sputter Target, 3″ Dia x 0.1875″ Thick |

| 869 | Tantalum pentoxide, Ta2O5 – Sputtering Target – 99.99% purity |

| 870 | Tantalum sputter target, Ta 99.95% pure, 1.5″ diameter x 0.25″ thick |

| 871 | Tantalum sputtering target 2.00″ diameter x 0.25″ thick- 99.95% pure Ta |

| 872 | Tantalum sputtering target 3.00″ diameter x 0.250″ thick- 99.95% pure |

| 873 | Tantalum sputtering target: 2.00″ diameter x 0.125″ thick- Ta 99.95%. ACI ALLOYS |

| 874 | Tantalum, Ta – Sputtering Target |

| 875 | Target Materials, Inc. Silicon Sputtering Target, 1.3″(dia)x0.125″(thick),99.999 |

| 876 | Target Materials, Inc. Tin (Sn) Sputtering Target, 1″(dia)x0.25″(thick),99.999% |

| 877 | Target Sputtering Desiccant Beads |

| 878 | TARGET,TK8859, Gold sputter target-K575X Emitech Products 99.99 |

| 879 | Technics Hummer HUM V Vent System Sputtering System SEM Sputter |

| 880 | Technics Hummer HUMMER Sputtering SEM Sputter PLATE ETCH SWITCH ASSEMBLY |

| 881 | TECHNICS HUMMER III SPUTTERING SYSTEM_AS-PICTURED_GREAT DEAL_FCFS |

| 882 | Technics Hummer Sputtering System High Voltage Process Control Unit |

| 883 | Technics Hummer V Sputtering System Sputter Coater AS-IS |

| 884 | Technics SSEM Sputtering Series 4, coater, Omron E5C4 |

| 885 | TEL / MRC SPUTTER 150 MM DAMPING RING, CLEANED, P/N 500006 |

| 886 | TEL / MRC SPUTTER 150 MM PART P/N 9000036 |

| 887 | TEL Tokyo Electron D125181-150SP Shield CR Wafer Holder Sputter Coated |

| 888 | Tellurium Metal, Sputtering Target Pieces, 99.999% (Trace Metals Basis), 100g |

| 889 | Tellurium Metal, Sputtering Target Pieces, 99.999% (Trace Metals Basis), 10g |

| 890 | Tellurium sputter target, 3″x 1/8″ thick, 99.999%, bonded for Meivac gun |

| 891 | Tellurium sputtering target, 2″x 1/4″ thick, 99.999% |

| 892 | Temescal 0101-8572-2 Model FCS-3200 Fast-Cycle Load-Lock Sputter System Manual |

| 893 | Temescal 0101-8572-2 Model FCS-3200 FastCycle Load-Lock Sputtering System Manual |

| 894 | Temescal Airco SC-3200 Sputtering Controller |

| 895 | Temescal Airco SC-3200 Sputtering Controller |

| 896 | Temescal Model BJE2400 Automatic R-F Sputter ETCH System Manual |

| 897 | Terbium sputtering target: Tb 99.9% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 898 | Testbourne Ltd Nickel Ni Sputter Target 99.99% Pure 3.00″x 0.25″Thick |

| 899 | The item is listed as a Top Rated Plus item Top Rated Plus |

| 900 | The item is listed as a Top Rated Plus item Top Rated Plus |

| 901 | TiAL 33/67 0025487c – Sputtering Target – 99.7% purity 160 x 12 mm |

| 902 | Tin – Sputtering Target – 99.99% purity |

| 903 | Tin Oxide (SnO2)) Sputtering Target, 76.2mm dia x 4.5mm thick |

| 904 | Tin Oxide- Sputtering Target |

| 905 | Tin SEM Sputtering target: Sn 99.99% pure, 57mm diameter x 0.5mm thick |

| 906 | Tin sputtering target Sn 99.995% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 907 | Tin/Aluminum 93.5/6.5 wt% sputter target, 2.92″ dia x 5mm, on Angstrom backer |

| 908 | Tin/Titanium sputter target:1:4 atomic, 99.99%, 3.00″ diameter x 0.25″ thick |

| 909 | Titanium Boride sputter target TiB2 99.5%, 2.0″ diameter x 0.25″ thick |

| 910 | Titanium Nitride High-Purity Sputter target: TiN 99.9%, 3″ dia x 0.125″, bonded |

| 911 | Titanium Oxide- black, TiOx- Sputtering Target – 99.99% purity |

| 912 | Titanium Selenide, TiSe2- Sputtering Target |

| 913 | Titanium SEM Sputtering target: Ti 99.995% pure, 57mm diameter x 0.1mm thick |

| 914 | Titanium SEM Sputtering target: Ti 99.995% pure, 63mm diameter x 0.1mm thick |

| 915 | Titanium sputter target 1″ diam x 0.125″ thick (1.3″ or 1.5″ diam also in stock) |

| 916 | Titanium sputter target 99.995% pure, 3″ diameter x 0.25″ thick |

| 917 | Titanium sputter target: Perkin-Elmer 200mm Delta: Ti 99.995% pure, 0.25″ thick |

| 918 | Titanium sputtering target 99.995% pure, 3.0″ diameter x 0.125″ thick |

| 919 | Titanium Sputtering Target Dia 80mm (3.15″) Width 60mm (2.36″) Purity 99.9% |

| 920 | Titanium sputtering target Grade II 8.00″ dia. x 0.25″ thick w/ copper backplate |

| 921 | Titanium Sputtering Target, 99.995%, 250mm Diameter x 6mm Thickness, by Atomergi |

| 922 | Titanium Target for Sputtering – 2.00″ Diameter, 0.250″ Thick – Kurt J. Lesker |

| 923 | Titanium, 99.995%, 18” x 3.5” x 0.250” Sputtering Target |

| 924 | Titanium-Tungsten, TiW- Sputtering Target – 99.99% purity |

| 925 | Ti-tungsten sputtering target, W/Ti 90/10 wt%, 99.99% 3″ diameter x 0.25″ thick |

| 926 | Ti-tungsten sputtering target, W/Ti 90/10 wt%, 99.99% pure, 2″ dia x1/4″ thick |

| 927 | TMD 8104 7678 / 81047678, ZnO/AL2O3 2wt% sputtering target, planar target |

| 928 | TMI Target Materials Inc Zirconium Zr Sputter Target 2.990″ Dia. x 0.25 Thick |

| 929 | Tokyo Electron Limited / TEL Model: D124680-150 Sputter Shield |

| 930 | TORIBE Scissors Kitchen Sputter Scissors KS-203 Dishwasher OK Japan F/S |

| 931 | Toribe Scissors Kitchen Sputter Scissors Ks-203 Made In Japan |

| 932 | TORR SQM160-S-2-R Thin Film Deposition Monitor 2-Inputs, RS-232, 120/240VAC |

| 933 | Tosoh 3481P-74001-45000V Quantum Sputtering Target 34820-29-027-250 Cu10% Ti10% |

| 934 | TOSOH Sputter Disk – Al-1% Silicon-1% copper |

| 935 | TOSOH Sputtering Conmag Target. Cobalt 99.9%. 0832F-27-000-300 for Varian 3180 |

| 936 | Tosoh Sputtering Target Chromium 6.74″ x 0.375″ — 6661E-24-000-280 |

| 937 | TRUSCO SPUTTERING & ABRASION-RESISTANT SUPPORT HOSE (L0.5m/10×6.5mm) TRH-6505 |

| 938 | TRUSCO SPUTTERING & ABRASION-RESISTANT SUPPORT HOSE (L0.5m/10×6.5mm) TRH-6505 |

| 939 | TRUSCO SPUTTERING & ABRASION-RESISTANT SUPPORT HOSE (L0.5m/12.5×8.5mm) TRH-8505 |

| 940 | TRUSCO SPUTTERING & ABRASION-RESISTANT SUPPORT HOSE (L0.5m/12.5×8.5mm) TRH-8505 |

| 941 | TRUSCO SPUTTERING & ABRASION-RESISTANT SUPPORT HOSE (L1.0m/10×6.5mm) TRH-6510 |

| 942 | TRUSCO SPUTTERING & ABRASION-RESISTANT SUPPORT HOSE (L1.0m/10×6.5mm) TRH-6510 |

| 943 | TRUSCO Torasuko sputtering felt 2.8X1000X1m 28CF-11 28CF11 Regular Inport |

| 944 | Tungsten oxide WO3- Sputtering Target |

| 945 | Tungsten sputtering target W 99.95% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 946 | Tungsten, W – Sputtering Target – 99.95% purity |

| 947 | Turbo Molecular Pump for Inline sputteranlage Leybold OPTICS Coater sputtering |

| 948 | UHV Magnetron Sputtering System for Multilayer Film Deposition on Large Optics |

| 949 | Ultek Varian Sputter Ion Pump 010-402 |

| 950 | Ultra Low Vacuum Pneumatic Actuated Valve Stainless 99B0649 Sputtering MKS |

| 951 | ULVAC PST-030AU Sputter ION PUMp |

| 952 | ULVAC PST-030AU Sputter ION PUMP |

| 953 | Umicore 0483078 Chromium 99.95% Sputtering Target AKQ515HEC Balzers BK209725-T |

| 954 | Umicore 0483428 Copper Cu 99.995% Sputtering Target AKQ515 Balzers BK209725-T |

| 955 | Umicore 0483484 NIFe 45.5 Sputtering Target 16×6 Balzers AKQ515 |

| 956 | Umicore 0483484 NiFe45.5 99.9% Sputtering Target AKQ515 Balzers BK221845-T |

| 957 | Umicore 0483591 NiFe18 99.9% Sputtering Target AKQ515 Balzers BK205602-T |

| 958 | Umicore AKQ515 Planar Magnetron Sputtering Target Kit NiFe45.5 wt% |

| 959 | Umicore BD483075-T TITANIUM 99.9% Sputtering Target AKQ515 Balzers BK205602-T |

| 960 | Umicore Nb 3N5 Target AK525 Sputtering Target CSBP-Cu-AK525 Material 3000101119 |

| 961 | Umicore Sputtering Target Silicone Si 99.9999% ARQ931 0704788 |

| 962 | Umicore Titanium 0483429 Sputtering Target 16×6 Balzers AKQ515 |

| 963 | Unaxis / Balzers ARQ900 Sputter Cathode |

| 964 | Unaxis / BPS Innenmaske 102050247 Sputter Mask |

| 965 | Unaxis ARQ131 silicone sputter target |

| 966 | Unaxis Indigo BD Sputter mask |

| 967 | UV Tech Material 6″ Sputtering Target Aluminum Type M2T5 6″ X 1 1/4″ thick |

| 968 | Vacuum Evaporator System Sputter Deposition Gun RF Plasma Brooks Cryo-Torr |

| 969 | Vanadium SEM Sputter target: V 99.95% pure, 57mm diameter x 0.2mm thick |

| 970 | Vanadium SEM Sputter target: V 99.95% pure, 63mm diameter x 0.2mm thick |

| 971 | Vanadium SEM Sputtering target: V 99.8% pure, 57mm diameter x 0.1mm thick |

| 972 | Vanadium sputtering target V 99.9% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 973 | Vanadium, V – Sputtering Target – 99.9% purity |

| 974 | VARIAN / L6427-301 / SPUTTER ION GAUGE BOARD |

| 975 | VARIAN / L6427-301 / SPUTTER ION GAUGE BOARD |

| 976 | VARIAN / VPW2871C2 / ARC COUNTER-3GUN, SPUTTERING POWER SUPPLY |

| 977 | Varian 00-664166-00 Insulator, Cathode for 3180 Sputtering |

| 978 | Varian 00-674163-00 Anode Cap for 3180 Sputtering |

| 979 | Varian 00-674163-00 Anode Cap for 3180 Sputtering |

| 980 | Varian 00-682216-00 Ceramic Clip Ring, 6″ for Varian Sputtering |

| 981 | Varian 00-684748-00 Shield, Heater, 5″ for Varian Sputtering |

| 982 | Varian 04-715634-01 Sputtering Power Supply Kilowatt Meter, VPW2871B2 |

| 983 | Varian 04-715634-01 Sputtering Power Supply Kilowatt Meter, VPW2871B2 |

| 984 | Varian 04-715634-01 Sputtering Power Supply Kilowatt Meter, VPW2871B2 |

| 985 | Varian Anode Cover 00-664198-01 for 3180 Sputtering |

| 986 | Varian Heator Insulator, 4″ Etch Ring 00-684270-00 for 3180 Sputtering |