Description

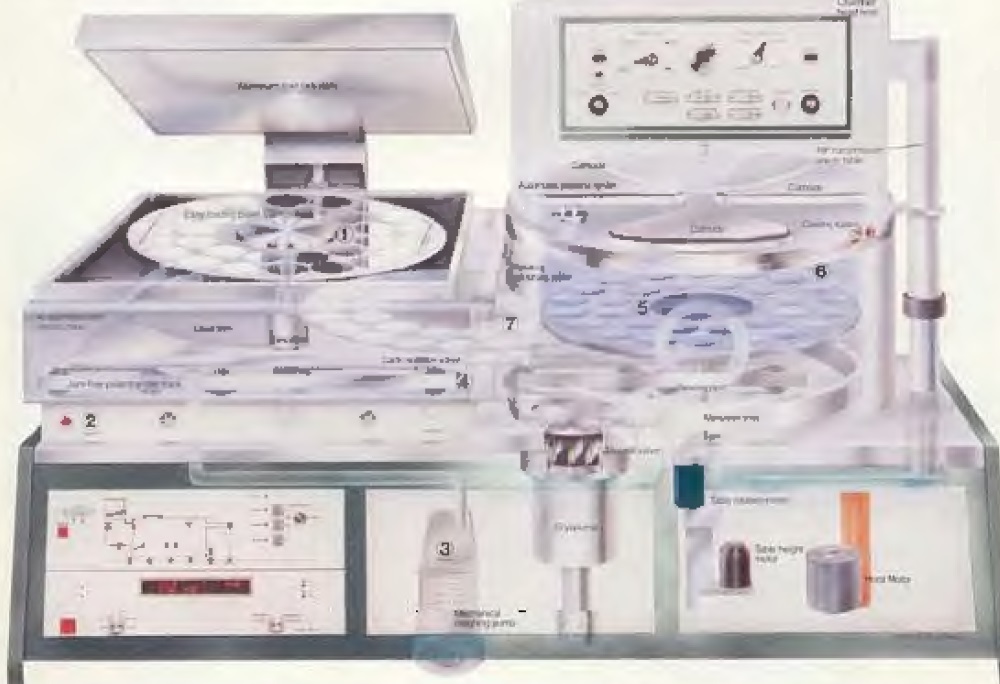

Model: Perkin-Elmer 4400

Category: Sputter

Original Equipment Manufacturer: Perkin-Elmer

Condition: Used. We sell them at complete, working, functional test with OEM specifications and the following customized configuration.

- DC magnetron Sputter, RF Diode Sputter, RF magnetron Sputter

- 1-4 of cathode.

Perkin-Elmer 4400 Sputtering Deposition Equipment Delta Cathode

- small sample to 6 inch wafer

- 1-2 gas lines with MFC

- RF Etch

- Bias function

- Loadlock heating function

- Chamber heating function (Occupy one cathode port).

- Co-Sputter function

- Reactive sputter function

Price: Please contact us

Quantity: 4

Valid Time: Subject to prior sale without notice

Lead Time: TBD

Location: U.S.A.

Warranty: 3 to 9 months.

erkin-Elmer 4400, Perkin-Elmer 4410, Perkin-Elmer 4450,Perkin-Elmer 4480, Perkin-Elmer 2400, Perkin Elmer 4400, Perkin Elmer 4410, Perkin Elmer 4450,Perkin Elmer 4480, Perkin Elmer 2400, Sputter, Magnetron Sputter, Diode Sputter, DC Sputter, RF Sputter, DC Magnetron Sputter, RF Magnetron Sputter, Co-sputter, Reactive Sputter, MRC, MRC 603, MRC 903, MRC 602, MRC 902, MRC 604, MRC 904, MRC 924, Plasma Etch, Dry Clean, Bias Function, Cathode, Load lock, Degas, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment,, Thin Film, Metal Thin Film, Thin Film Deposition, PVD, Physical Vapor Deposition

Perkin-Elmer Sputter System Information for your reference only.

As new commercial and industrial technologies emerged and grew, so did the use of sputtering as a technique for deposition thin films of desired characteristics. The Perkin Elmer 4400 and Perkin Elmer 2400 Series sputtering systems were designed to meet the changes of this changing technical environment, whether in development or production.

With an installed base of more than thousands of systems, Perkin-Elmer was a leading supplier of sputter deposition equipment for high technology application in 1990’s. The Perkin Elmer 2400 Series sputtering systems were used not only in the production of semiconductor devices but also in the development and manufacturing of thin film recording heads, thin film resistors and capacitors, optical coatings, gallium arsenide lasers and fiber optics.

Quality, performance and stability backed by more than two decades of experience in vacuum technology and UHV design were built into every Perkin Elmer sputtering system. The Perkin-Elmer4400 and Perkin-Elmer 2400 Series were designed for flexibility offering a wide range of operating and process modes. The highest quality construction and components assure reliable operation and an ultra clean vacuum environment to yield consistently reproducible results. Every Perkin Elmer sputtering system was supported by years of technological experience and backed by a worldwide sales and service organization dedicated to prompt courteous service.

The Perkin Elmer4400 and Perkin Elmer2400 Series of sputtering systems represent just one part of the Perkin Elmer Semiconductor Equipment Group’s unique “one source” approach to cost-effective VLSI production. From mask making to photolithography, dry etching and sputtering deposition, the Semiconductor Equipment Group provides an integrated line of performance-proven production equipment specially designed to address each critical process. This “one source” solutions designed to meet the semiconductor industry’s demands throughout the 1980’s.

Versatile Systems For Any Sputtering Need

The Perkin Elmer 4400 Series, designed specially for high throughput production environments, features a high capacity load lock and a broad range of operating models to accommodate virtually any thin film coating requirement.

- High Throughput

The Perkin-Elmer4400 Series fast cycle load lock, cryogenic pump, and full flood Meissner trap ensures quick turnaround on batch loads. High throughput are achieved for a full range of substrate sizes and shapes.

- High Yield

A rotating substrate table for multi-pass deposition helps assure high uniformity and run-to-run repeatability. Simplicity of mechanical design with a minimum number of moving parts in the process chamber minimizes the generation of defect-causing. Easy loading pallet designs reduce wafer breakage. Consistently clean vacuum conditions assure reproducible high quality films.

- Optimum Process Control

The Perkin-Elmer4400 Series provides a broad choice of target materials, machine operating models, pressure and gas controls, cathode configurations and power levels. Operating models include DC magnetron, RF magnetron, RF diode, bias sputter, reactive sputter, co-sputter and RF etch.

- Total Control of Critical Film Characteristics

The Perkin-Elmer 4400 Series systems yield excellent films for a wide variety of materials including aluminum alloys, platinum silicide, titanium-tungsten, nichrome-gold, silicon nitride, silicon dioxide, precious metals and permalloy.

Deposition Of Thin Film for VLSI Geometries

Perkin-Elmer 4400 Series System configurations

No single cathode design can effectively meet the varied needs of different users or even the possible multiple needs of one user. Every film requires an optimum combination of target material, size, and shape for its most efficient fabrication. Recognizing these realities, the Perkin Elmer 4400 Series provides two distinct cathode configurations: 8″ circular and delta-shaped.

- Perkin Elmer 4400

A general purpose sputtering system employing up to three 8″ diameter circular cathodes in DC magnetron, RF magnetron, or RF diode configurations. Power options are available up to 2 kw RF and 5 kw DC.

- Perkin Elmer 4410

A delta target sputtering system designed for high rate deposition of metals and metal alloys. The Perkin Elmer4410 is also adaptable to the deposition of dielectrics and employs up to three delta-shaped cathodes in DC magnetron, RF magnetron, or RF diode configuration. Power options are available up to 3 kw RF and 10 KW DC.

- Perkin Elmer 4450

A delta target sputtering system, similar to the Model Perkin Elmer4450 with load lock pumping and heating incorporated as standard features.

- Perkin Elmer 4480

A delta target sputtering system of identical design to Model 4480 but including cassette-to-cassette loading as a standard feature.

As VLSI geometries routinely approach the one to two micron region, new problems arise in thin film deposition technology, dry etched vertical walls, deep vias and multiple level structures must all be uniformly covered with no microcracks or cusping. Film deposition systems must be able to provide uniform conformal coverage of these tightly packed structures to minimize interconnect resistances and maximize yields.

Substrate heating has improved step coverage of LSI structures by increasing the surface mobility of the depositing atoms. Additional techniques are now being used to further enhance coverage of planar-magnetron-sputtered films. Perkin Elmer 4400 and Perkin Elmer 2400 Series sputtering systems utilize “multi-pass” design and RF bias to maximize film coverage of VLSI structures.

As geometrical features get smaller, new materials will be employed. Metallization layers now include the use of diffusion barriers and low resistance gate and interconnect materials such as refractory metal silicides.

Substrate Motion

By utilizing rotating substrate table, Perkin Elmer sputtering systems allow wafers to be coated by multiple passes through the target region. This technique can minimize shadowing effects sometimes encountered in the single pass mode or center-to-edge effects found in static deposition systems, while maximizing target material utilization, step coverage and device yield.

RF Bias

The application of RF bias to the substrate re-sputters deposited material from horizontal surfaces onto the surrounding vertical walls of the wafer. Step coverage of 50% or more can be achieved on vertical steps and deep vias can be uniformity covered with RF bias and multi-pass technologies.

Co-sputtering

The deposition of contamination-free, low-resistance refractory metal silicides request the use of the purest materials. Co-sputtering provides the optimum method for depositing these films from pure elemental targets, wile providing a convenient means to control the stoichiometry of the films. Oxygen and carbon contamination and target-to-target stoichiometric non-uniformities are minimized using dual target sputtering and multi-pass techniques.

High Vacuum Technology for Maximum Process Control

- Fast Cycle Load Lock Operation

The Perkin Elmer 4400 Series high capacity load lock system eliminates the need to break vacuum; thereby reducing both pumpdown time and contamination of targets and internal chamber surfaces. Transfer of a full pallet load of wafers from air to the process chamber and pumpdown to a base pressure of 5X10-7 Torr can be accomplished in less than 3.5 minutes.

- Contamination-free Cryogenic Pump

The process chamber vacuum system incorporates a contamination-free, closed cycle, two-stage helium cryopump (turbomolecular pump optional). Under load conditions, 70oK is maintained in the first stage and less than 15oK in the second stage. This assures efficient, rapid pumping of most atmospheric gases and reduction of partial pressures of most unwanted gas species to acceptable levels. An ultimate vacuum of 10-6 scale can be attained with typical pumping speeds of 1000 l/s for nitrogen, 1100 l/s for hydrogen and 4200 l/s for water vapor.

- The Meissner Trap

A full flood Meissner trap mounted in the process chamber maintains an efficient pumping speed for water vapor of 30,000 l/s during deposition or sputter etching. The Meissner trap pumps water vapor at a maximum rate even with the high vacuum cryopump throttled. This assures good quality films in critical processes such as the deposition of aluminum alloys.

- Substrate Degassing

The Perkin Elmer 4400 Series systems can be equipment with load lock heating and turbomolecular pumping to degas substrates prior to processing and minimize pumpdown for critical processes such as the deposition of aluminum alloys and other oxidizable metals. This further reduces the partial pressure of undesirable gases such as water vapor.

- Vacuum Control

All Perkin-Elmer 4400 Series systems are equipped with ion and thermocouple gauges. A wide-range gauge controller monitors and digitally displays vacuum levels from 10-11 to 200 microns providing continuous monitoring of operating pressure. Additional thermocouples provide inputs to the automatic pumpdown control and automatic lock control.

The Circular Cathode Systems-Model 4400

Model 4400 is designed for use in production environments or process development. Up to three 8-inch circular cathodes and a 350oC quartz lamp heater may be installed in the process chamber to accommodate a variety of processes. An optional RF power sputtering network enables the RF/RF Co-deposition of two different materials. Precise stoichiometries of graded interface may be easily achieved.

The Model 4400 is routinely used for such processes as the deposition of Cr-Co for recording discs, Cr-Cu for backside metallization, TaSi2 for gate metallization and Si3N4 for interlayer dielectric.

Chrome-Cobalt

A precise ratio of chrome to cobalt is readily achieved with co-deposition using the RF power splitting option, ideal film temperature in the range 170 oC-200 oC can be easily obtained for optimum grain growth and orientation.

Chrome-Gold

The films resulting from the sputter deposition of chrome-gold are superior to those obtained from evaporation processes, pre-etching prior to deposition removes native oxide improving film adhesion and RF magnetron deposition results in lower thin film temperature and less gold interdiffusion.

Tantalum Silicide

Tantalum silicide of any desired stoichiometry is easily deposited with co-sputtering using the RF power splitting module. Annealed film resistivity of approximately 2.3 ohms per square can be obtained from a typical 2000 angstrom film of tantalum silicide. Within further advances in process technology, the UHV design of the 4400 will enable it to accommodate the deposition of refractory metal silicide films of even higher resistivities.

Silicon Nitride

With RF bias deposition, silicon nitride films exhibiting low pin-whole count, good step coverage and low stress can be readily deposited in the model 4400.

The RF Power Split Module

The two-way adjustable RF Power Split Module provides precise control of the level and ratio of RF energy from a single RF generator to two 8″ diameter cathodes simultaneously. A total of 2 kw may be applied with power ratio adjustable between 5% and 95%. This module is idea for use with the Model 4400 and 2400-8SA in R&D and in low volume production applications, where precise control of alloying of film properties is desired.

Features

- Efficient 8″ round cathodes

- High throughput operation

- High Uniformity

- DC, RF Etch and Bias operation

- Ultra Clean vacuum system

- Load lock operation

- UHV design

- Flexible for development or production use

- Substrates up to 6″ diameter

- Various pumping and power options

- RF/RF co-sputtering option

- Optional gas controllers

A Wide Range of Process

The following processes have been demonstrated in the Model 4400

| Al+W | Cr/SiO2 | SiC | Ti+Au |

| Al+Ti/W+Ag | InSnO | SiO2 | Ti+Au+Ni |

| Al2O3 | Mo | SiO2+O2 | Ti/W |

| Ag | MoSi2 | Si+N2(Si3N4) | Ti/W+Au |

| Au | Mo2Si5 | Si+N2+B4C | Ti/W+Au+Ta |

| C | Mo5Si3 | Ta | Ti/W+Al/Si |

| Cr | Ni | TaC | Ti/W+Ni/Cr+Au |

| Cr/Co | Ni/Cr | Ta+Au | Ti/W+Pt |

| Cr/Au | Ni+Ni/Cr | TaSi2 | W |

| Cr+Cu | Ni/Fe | Ta+SiO2 | W+Al2O3 |

| Cr/Si | Ni/Fe+Cu+SiO2 | TiO2 | Zn |

| Cr/SiO | Pt | TiO2+Cr | ZnO2 |

| Zr |

Aluminum Alloy Sputtering

The Perkin Elmer Delta cathode systems(Model 4410, 4450, 4480) are ideally suited to aluminum alloy deposition for gate contact and interconnect metalization.

- Utilization and Rate

A Delta cathode system achieves an instantaneous deposition rate for aluminum alloys of 12,000 angstroms/minute. The substrate pallet can be in excess of 200 angstroms/kw minute with sputtered material utilization approaching.

- Uniformity and throughput

Delta cathode systems maximize uniformity of deposition, exhibiting a +/-7% uniformity over a 6″ annular width. Optional high performance Delta cathodes yield a uniformity of +/-5% over a 73/4 inch band, allowing processing of up to 22 100mm wafers per cycle. Standard Delta cathodes process 50-60 100mm wafers per hour while optional high performance Delta cathodes yield throughput in excess of 80 100mm wafers per hour.

A particular advantage of a circular batch sputtering system is its adaptability to different substrate sizes. The Model 4410 and other delta cathode systems can easily handle substrate size up to 8 inches in diameter. Standard wafer size of 3 inch, 100mm, 125mm and 150mm can easily be accommodated.

| TYPICAL CAPACITY-UNIFORMITY DATA | |||

| Wafer Size | Loading Capacity | Deposition Uniformity | |

| Std Delta | High Perf. Delta | ||

| 3inch | 30 | +/-7% | +/-5% |

| 100mm | 22 | N/A | +/-5% |

| 14 | +/-7% | +/-4% | |

| 13 | +/-5% | +/-4% | |

| 125mm | 10 | +/-7% | +/-5% |

| 9 | +/-4% | +/-4% | |

| 150mm | 8 | +/-12% | +/-5% |

| 7 | +/-7% | +/-4% | |

| 8inch | 5 | +/-14% | +/-7% |

The Delta Cathode Systems-4410/4450 And 4480

- Resistivity

Perkin Elmer sputtering systems ensure low film resistivity by minimizing partial pressure of oxygen and nitrogen below 1X10-7 Torr. With total system background pressure of 5X10-7 Torr and an instantaneous deposition rate in excess of 8500 angstroms/minute, near-bulk resistivity for aluminum alloy films can be achieved.

- Film Hardness

By keeping oxygen content below, film hardness for typical 1 micron thick aluminum silicon films can be kept below 100 kg/mm2 after annealing at 500oC, minimizing bonding failures.

- Specularity

High quality aluminum alloy films of 70-90% relative reflectance are routinely produced in high rate DC Delta magnetron systems, yielding wafers easily accommodated in today’s projection mask aligners.

Optional load lock pumping and wafer degassing further minimize water vapor and hydrogen, the principal contaminants that contribute to hillock growth and poor specularity. As metallization films become thicker and specularity degrades, further reduction of unwanted gases can be achieved through the use of supplemental hydrogen getter pumping in the Model 4410 and other Delta cathode systems.

- Step Coverage

The high rate sputtering made possible with Perkin Elmer Delta DC magnetron cathodes produces sufficient heat to maintain film temperature in the ideal range. Heating the substrate in this manner and re-sputtering the deposited material through RF bias improves coverage of vertical surfaces in VLSI structures. It also minimizes cracks and cusping.

- Optional High Performance Delta Cathodes

Provide more uniform deposition over a wider annular region of the pallet. A maximum of twenty two 100mm wafers can be loaded yielding 50% more throughput for a typical metallization process. The HIGH THROUGHPUT option consists of a modified shaping aperture, a high performance Delta cathode and a pallet nested for twenty two 100mm wafers. The region of high uniformity is extended across the total 8″ annular width of the pallet. A uniformity of +/-7% is achieved across a 73/4 inch band suitable for mounting two concentric rows of 100mm wafers. This wide brand of uniformity means that 51/4“, 8″, or 14” recording discs can be accommodated in the system.

- The Delta Cathode Dual Deposit Sputter Module

The Delta Cathode Dual Deposition Sputter Module, operable in either a dual DC mode or DC and RF mode, is designed for higher throughput and larger scale production. Separate power suppliers allow independent application of either DC or RF energy to two delta cathodes simultaneously. The dual deposit sputter module for Models 4410, 4450 and 4480 is the choice for co-sputtering of refractory metal silicides for VLSI circuits. The dual deposit sputter modules and the co-sputtering technique allow the deposition of contamination-free films.

Features:

- High rate Delta DC magnetron

- High throughput operation

- Fully process characterized for aluminum alloys

- High uniformity

- DC, RF, Etch, and Bias operation

- Ultra clean vacuum system

- Load lock operation

- UHV design

- Flexible for development or production use

- Any size substrates up to 8″ diameter

- Various pumping and power options

- Optional system and process controllers

- Cassette to cassette operation(Model 4480)

- Co-sputter option for silicides

- Operation gas controller

| PERFORMANCE FOR TYPICAL METALLIZATION PROCESS-100mm WAFERS | ||

| Standard Delta System | High Throughput Delta Systems | |

| Pallet capacity | 14 | 22 |

| Uniformity | +/-7%(63/4“) band | +/-5%(73/4” band) |

| +/-7%(8″ band) | ||

| Typical Target Life | 3220 wafers | 4070 wafers |

| Typical Deposition Rate | 200 Angstroms/kw-min | 170 Angstroms/kw-min |

| Typical Deposition time | 5 minutes | 5.9 minutes |

| *Runs per hour | 4.0 | 3.8 |

| Throughput | 56 wafers/hour | 83 wafers/hour |

| * Assumes 10 minute pumping, wafer exchange and venting cycle, some processes require pre-heating, extending the loading cycle by as much as 5 minutes. | ||

| Delta Cathode Systems Performance Specifications(Typical) | |||

| Material | Al/1%Si | Al/1%Si/2%Cu | Al/4%Cu |

| DC Power | 10 kw | 10 kw | 10 kw |

| RF Bias | -25V | -25V | -25V |

| Base Pressure | 5X10-7 Torr | 5X10-7 Torr | 5X10-7 Torr |

| Pumpdown Time | 3.5 min. | 3.5 min. | 3.5 min |

| Argon Pressure | 8X10-3 Torr | 8X10-3 Torr | 8X10-3 Torr |

| Table Rotation | 2-5 rpm | 2-5 rpm | 2-5 rpm |

| Deposition Rate | 2000 Å /min | 2000 Å /min | 2000 Å /min |

| Film Temp(max) | 375oC | 375oC | 375oC |

| Film Thickness | 1.0 microns | 1.0 microns | 1.0 microns |

| Step Hight | 1.0 microns | 1.0 microns | 1.0 microns |

| Step Slop/Coverage | 70o/70% | 70o/70% | 70o/70% |

| 80o/60% | 80o/60% | 80o/60% | |

| 90o/50% | 90o/50% | 90o/50% | |

| Specularity | 70-75% | 80-85% | 90-95% |

| Resistivity | 2.85-2.90μΩ-cm | 2.95-3.00μΩ-cm | 2.95-3.00μΩ-cm |

| Grain Size | 1-2μm | 0.3-0.5μm | 0.3-0.5μ |

| Film Hardness | |||

(Annealed)85kg/mm2100kg/mm2120kg/mm2CV Shift0.25V0.15V0.15V*Uniformity+/-7%+/-7%+/-7%* Typical results with Standard Delta Cathodes. Higher uniformity and throughput can be achieved with high performance Delta Cathodes and high throughput option. Throughput is process dependent and may vary depending on etch and pre-heat cycles.

Series 2400

Highest Quality Sputtering-

Superior Performance-

Wide Selection of options-

In a laboratory or low-volume production environment, where the high throughput levels of the 4400 Series are not required, the 2400 Series is the ideal alternative for high quality sputtering in a wide variety of applications.

Model 2400-8SA

The Perkin-Elmer Model 2400-8SA features a large 211/2” rotating, water cooled annular table with a capacity of sixty-four 2″, thirty 3″, or thirteen 4″ wafers.

Used in conjunction with a cathode shaping aperture, the rotating table permits high uniformity. A 4″ wafer vertical range of the table facilitates coating bulk substrates. As an added feature, up to three 8″ round cathodes may be specified allowing sequential deposition from several targets or alternately, static deposition or heating from any target position.

Power Splitting is an optional feature of the 2400-8SA system. With this feature, RF power can be applied to two cathodes simultaneously in any desired ratio from 5 to 95%. Combined with the continuous substrate rotation feature, an infinite number of alloy compositions can be developed simply by varying the power division between target.

Model 2400-8L

The Model 2400-8L load lock system ensures a constant inert gas or vacuum environment allowing rapid pumpdown to base pressure and elimination of target pre-cleaning. High partial pressure of water vapor is no longer a problem, even in areas of high humidity. Additional water vapor pumping is possible with an optional Meissner Trap. By eliminating the need to break vacuum in the process chamber, the 2400-8L load lock reduces both pumpdown time and contamination of targets and internal chamber surfaces. Load lock pumping is provided by a mechanical pump which is shared with the process chamber vacuum system. Load lock pumpdown and pallet transfer are automatically controlled. Sequence and valve position are displayed on front control panels.

A water-cooled 8″ diameter substrate table rotates the pallet 360o and automatically aligns it precisely under any one of the three targets or the etch position. Substrates can be loaded, processed, and unloaded in minutes improving run to run yields. A full pallet of wafers can be transferred from air to a properly maintained process chamber and pumped down to a base pressure of 5X10-7 Torr in less than five minutes.

Series 2400-Capabilities, Features, Options

- High Uniformity

Careful cathode and chamber designs mean high uniformity,. Integral copper channels in the anode tables insure even distribution of cooling water and RF power.

- High Throughput

The 2400-8SA features a 211/2” table which enables processing of large wafer batches. The 2400-8L utilizes a smaller pallet but provides a unique load lock system to dramatically reduce pump-down time. Either approach maximizes efficiency.

- Maximum Process Control

Both 2400 Series systems offer a wide choice of target materials, machine operating models, and gas controls with capability to perform a variety of thin film tasks.

- RF Bias

The Perkin-Elmer 2400 Series RF Bias capability enables high quality films with a variety of materials. The RF bias provides improved step coverage, controllable intrinsic stress for metal or dielectric films, improved alloying materials and stoichiometry, resistivity that approaches bulk values, precisely controlled film densities and impurities and reduced argon content.

- Uniform Deposition

The 2400-8SA and 2400-8L use uniformity shaping apertures to compensate for the geometry of the cathode sputtering pattern. The rotating substrate table further improves uniformity in the 2400-8SA. The 2400-8L utilizes a double-disk dark space shield to eliminate edge sputtering from the cathode plate and provide exceptional plasma confinement.

- Operation Mode Selection

In all 2400 systems, the mode selector switch provides a choice of modes:sputter deposit, bias sputter and sputter etch.

- Standard RF Features

Servo-Match automatic turning maintains proper turning despite variations in target emission, pressure or RF power. A power stabilizer holds RF power constant.

FEATURES

The 2400-8SA Rotating Table Multi-Target System

- Sequential deposition from DC magnetron, RF magnetron and conventional RF cathodes

- Simultaneously sputtering from 2 targets

- High deposition rates for metals and dielectrics

- Low substrate temperature in both RF and DC magnetron deposition modes

- Single pass or multi-pass capability

- Servo-Match automatic turning

- High loading capacity

- Three target capability

The 2400-8L Load Lock Multi-Target System

- Load lock for reduced pump-down time

- Remotely adjustable anode/cathode spacing

- No cross-contamination

- Pallet heated on substrate table with rapid cool-down

- Servo-Match automatic turning

- Fast turnaround through automated operation.

- Three target capability

Series 4400/2400-Options

| Options | 4400 | 4410 | 4450 | 4480 | 2400-8L | 2400-8SA |

| Process Chamber Heater, 350oC | X | X | X | X | X | X |

| RF/RF Power Split, Co-Sputter | X | X | ||||

| Dual DC;RF/DC. Co-Sputter | X | X | X | |||

| Process Chamber Turbo Pump | X | X | X | X | X | X |

| Process Chamber Diffusion Pump | X | X | ||||

| CTI-8 Cryopump | X | X | X | X | X | X |

| Hydrogen Getter Pump | X | X | X | X | ||

| Load Lock Heat, 200oC | X | X | Std | Std | ||

| Load Lock Turbo Pump | X | X | Std | Std | ||

| 5kw DC Power Supply | X | X | X | X | X | X |

| 10kw DC Power Supply | X | X | X | |||

| 1kw RF Generator | X | X | X | X | X | X |

| 2kw RF Generator | X | X | X | X | X | X |

| 3kw RF Generator | X | X | X | |||

| RF Power Stabilizer | X | X | X | X | X | X |

| RF Power/Voltage Stabilizer | X | X | X | X | X | X |

| Gas Controller | X | X | X | X | X | X |

| Digital Clock Timers | X | X | X | X | X | X |

| Process Sequence | X | X | X | |||

| High Throughput Option | X | X | * | |||

| DC Sputter/RF Bias Option | X | X | X | X | ||

| * Useable in Manual Load Mode only | ||||||

Model 4410

DeltaTM Cathode Production Sputtering System

Perkin-Elmer Ultek Division

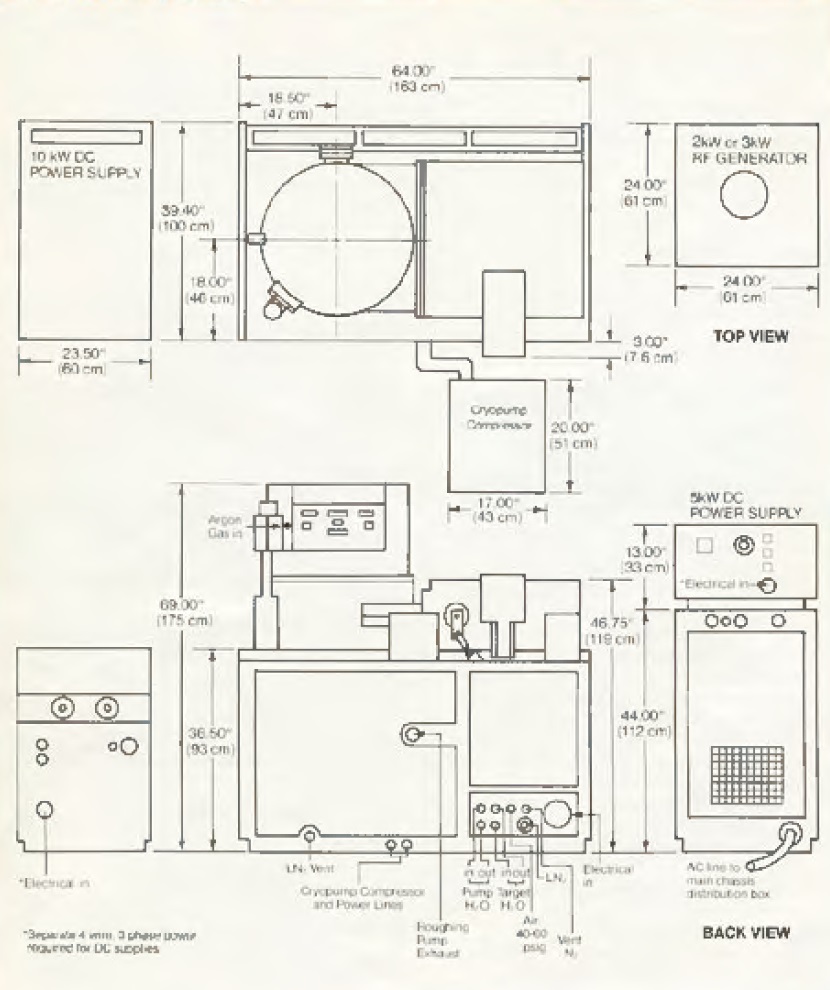

MODEL 4410 SPECIFICATIONS

Typical Process Results

High quality metal films can be routinely achieved:

Material:Al-1%Si

Power:9kw

Table rotation:10 rpm

Argon pressure:8 mTorr

Film thickness:1.04 microns

Deposition time:5.8 minutes

Step height: 1.10 microns

Step slope: 80o

Step coverage: 62% horizontal-to-vertical

Specularity: 65-75%

Resistivity: 2.85μΩ-cm

Grain size:2 microns

Process Chamber

- 28″ diameter X 12″ high stainless steel cylinder with 6″ CF flange viewport and load lock port

- 28″ diameter stainless steel top plate with 3 delta cathode ports

- 28″ diameter stainless steel base plate

- 11/2” air-operated roughing isolation valve

- Solenoid-operated gas inlet valve

- 3/8” solenoid-operated vent valve

- 11/2” blanked-off leak check port

- Removable deposition shields

- 23″ diameter, 3-position water-cooled annular substrate table with adjustable 1-10 rpm SCR motorized table drive

- Full circle shutter with vane shutter

- Chain drive pallet carrier transport

- Automatic plasma igniter

- Heavy duty electric hoist

Load Lock

- 30″ x 28″ x 8″ stainless steel load lock chamber with aluminum cover

- 2″ air-operated roughing isolation valve

- 3/8” solenoid-operated vent valve

- 23″ diameter molybdenum annular substrate pallet

- Pallet carrier and chain drive transport

Vacuum System

Roughing

- 7 cfm mechanical pump for process chamber and load lock roughing

- 2″ diameter roughing lines with electropneumatic valve

- Surface-area Versa-trapTM in roughing line

High vacuum pumping

- 2 stage cryopump with 1000 l/s pumping speed for air, including chevron, water-cooled compressor and lines, automatic regeneration controller and plumbing kit.

- 71/2” O.D. (6″ ASA) aluminum air-operated gate valve

- Air-operated venetian blind throttling valve

Residual gas pumping

- Full flood Meissner trap with 30,000 l/s pumping speed for water vapor

- Insylated LN2 lines

- LN2 sensor, solenoid and relief valve

Control

- Vacuum gauging package including basic digital vacuum gauge control (DGC II), ionization tube and two thermister tubes

- Automatic pump-down controller

- Automatic lock controller

Options

- Diffusion-pump system including 1500 l/s oil diffusion pump, LN2 chevron baffle, water-cooled baffle and water-flow switch.

- Turbomolecular-pumped system including 450 l/s turbo pump, foreline manifold with 11/2” air-operated isolation valve, and water-flow switch(less throttling valve)

- Polycold-compatible quick-purge Meissner trap.

Sputtering Control Module

- 3 kw water-cooled RF matching network

- RF power on/off switch

- RF power level control

- 4 position rotary sputter mode selector

- 3 position rotary target selector

- 2 position shutter position switch

- Manual load and tune controls

- 15-turn vernier 0-10% bias control

- Forward and reflected RF power meters

- Substrate bias meter

- Target bias meter

- Target-to-table spacing meter

- Servo-MatchTM automatic turning (mounted in lower console)

Cathode Options

- Delta DC magnetron cathode assembly with water-cooled backing plate and anode

- Delta-to-8-inch round cathode adaptor

- 8″ diameter RF magnetron cathode assembly

- 8″ diameter RF diode assembly

- 8″ diameter DC magnetron cathode assembly

- Delta blank-off plate

- MagnabondTM 8-inch round target kit for DC cathodes

- Bolt-on Delta target kit

Power Options

- 2 kw RF Generator

- 3 kw RF Generator

- 5 kw programmable DC magnetron power supply including digital clock timer

- 10 kw programmable DC magnetron power supply including digital clock timer

Utilities

- Rear-mounted electrical, water, gas and LN2 inlet panel

- Power distribution box

- Water-flow switch panel and manifold

System Options

- Precision 3 rpm to 5 rpm servo-driven table drive

- Water-cooled process chamber

- Water-cooled top plate

- Dura gas inlet system

- Wide range digital vacuum gauge control

- Continuous viewing vacuum port

Accessories

- Load lock pumping and heating system including 100 l/s turbomolecular pump, 17.7 cfm mechanical pump, 200oC heater and controller

- Microprocessor for machine and process control

- Programmable RF power stabilizer

- DC sputter with RF bias

- Process chamber 350oC heater (mounted in cathode position)

- Digital clock timers

- Annular pallet nested for 64 2-inch,30 3-inch or 13 4-inch wafers

- Polycold refrigeration system for Meissner trap

- Delta target copper backing plate

- Pressure or flow controllers

Microprocessor Operation Option

Ultek’s microprocessor controller option permits automated control of machine functions and process parameters including load lock operation, pump-down venting and all process sequences. Up to five 16-step process sequences can be stored in the system’s memory to facilitate process change.

An interactive CRT facilitates programming. Unconditional looping is available for repetitive processes. Other capabilities include: program listing, hard copy records and interface with other computer systems.

THE DELTA CATHODE SYSTEM:MODEL 4410

Perkin-Elmer’s Model 4410 delta cathode production sputtering system is designed for high yield in production environments demanding maximum throughput for metal deposition. It also provide a high level of flexibility in process control for other materials.

The 4410 uses a delta-shaped cathode that eliminate the need for a large-area uniformity-shaping aperture. This dramatically increases throughput while maintaining high wafer-to-wafer uniformity.

Contrasted with circular cathodes, target utilization is substantially higher. Up to 35% of the target can be sputtered before target change, and some 60% of the sputtered material actually reaches the substrate pallet. This results in a lower cost per wafer and less frequent target changes. Up to three delta or 8-inch round targets may be installed for sequential deposition of three different materials without breaking vacuum.

The 4410 employs a fast cycle load lock, two-stage cryopump and full flood Meissner trap to maintain the process chamber at high vacuum and in a clean condition at all times. The process chamber is fabricated of stainless steel for contamination-free performance. A base pressure better than 5 X 10-7 Torr is achieved within 3.5 minutes from loading substrates into the load lock. Typical cycle time, with optional load lock heating and pumping, is 12 to 15 minutes for the deposition of 1 micron of aluminum.

System Highlights

- High rate delta DC magnetron sputtering: Aluminum and aluminum alloys can be sputter deposited at rates in excess of 1800 Å /min, with loads of thirty 3-inch or thirteen 4-inch wafers.

- High throughput operation: Automated load lock and controller sequences provide for efficient pump-down and pallet transfer to process chamber, maximizing throughput.

- High uniformity: +/-7% deposition uniformity guaranteed with water-cooled rotating annular substrate table;+/-5% achievable.

- The right sputter mode for each application: Sputter deposit, 0-10% RF bias sputter. DC bias sputter, sputter etch to 2 kw, RF magnetron, RF diode, DC delta magnetron.

- Ultra-clean vacuum: Cryopump and Meissner-trapped process chamber ensures contamination-free conditions especially important for critical processes such as the deposition of aluminum and platinum.

- Designed for operator safety: Two-button operation initiates pump-down and load sequence. Safety interlocks on DC and RF suppliers.

- Easy maintenance: Removable deposition shields permits easy system cleaning. Automatic cryopump regeneration minimized downtime and inconvenience.

- Key function clearly displayed: Valve position and system status are continuously displayed by quick-reading LEDs on front panels.

- Easy wafer loading: Tweezer grooves facilitate wafer loading. Nested pallets are optional.

- A fail-safe system: Water flow switches on cathodes, matching network and vacuum system automatically shut the system down in case of cooling system failure.

The Sputtering Process

Sputtering is a momentum transfer process in which atoms from a cathode/target are driven off (or sputtering) by bombarding ions. In this process the momentum of the bombarding particles is more important than the energy. For example , a hydrogen or helium ion accelerated to 3,000 eV will cause very little sputtering compared to an ion of argon (which is chemically inert) with the same 3,000 eV energy, simply because the much higher hydrogen or helium ion has much less momentum.

Sputtered atoms travel until they strike a substrate , where they are deposited to form the desired thin film. As individual atoms, they can be chemically active and form compounds with the ions and atoms of the bombarding gas. For this reason, inert argon typically is used as the bombarding gas. In some applications, however, a reactive gas is intentionally added to the argon to alter the chemical composition of the deposited film (e.g., nitrogen gas in combination with tantalum sputtering to form tantalum nitride, TaN).

When argon atoms strike the target, their electrical charge is neutralized and they return to the process as atoms. If the target is an insulator, the neutralization process results in a positive charge on the target surface. The charge may grow so large that the bombarding ions are repelled and the sputtering process stopped. To allow the process to continue, polarity of the target must be reversed, attracting enough electrons from the discharge to eliminate the surface charge. This periodic reversal of polarity is accomplished automatically by applying RF voltage to the target assembly ( hence the term “RF” sputtering).

Of interest here is the diode rectifier-like behavior of the target and discharge systems. This results from the vast difference in mobility of ions and electrons. Electrons , being so much fast, are attracted in greater numbers to the target during the positive half-period of the RF voltage than are ions during the negative half-period. Thus, the target develops a negative DC bias.

4400-Series Production Sputtering Systems perform a number of sputtering process, each of which is ideal for a different application.

RF Diode Sputter Deposition

When the vacuum set point is reached, sputtering gas (typically argon) is introduced in the process chamber at a pre-selected rate (typically 40 sccm). A plasma, or self-sustaining glow charge , initiated by an automatic plasma igniter, appears when RF power is applied between the target and electrical ground, ionizing the argon gas.

A negative (-) potential applied to the target, as a result of the applied RF power, attracts the ionized argon at a momentum determined by a) the magnitude of applied potential and b) the mass of the ion. The momentum of the incoming ion is transferred to the target material, causing surface atoms or molecules of target material to be ejected (sputtered). These sputtered atoms travel across the gap separating the target (cathode) and substrate table (anode), and are deposited on the substrate (wafers) which are arranged on the substrate pallet.

RF Magnetron Sputter Deposition

RF magnetron and RF diode sputtering are very similar, except that during RF magnetron sputtering a magnetic field deflects the secondary electrons (which are produced during normal sputtering operation) away from the substrates. The sputtering process, which is cooler than RF diode sputtering, permits materials to be sputter deposited on substrate at lower temperatures and greatly reduces the chance of radiation damage to delicate substrates.

Because the impedence of a magnetron is lower, higher power densities are possible at lower potentials, effecting high sputter rates.

DC Magnetron Sputter Deposition

DC magnetron targets enhance the plasma density and increase the sputtering rate, by trapping electrons in an electromagnetic “envelope”. This “envelope” is formed when lines of the magnetic field enter and exit the target face and when the loci of maximum transverse magnetic fields form a closed figure. Because the currents involved are very large, a separate, positively-biased anode (a dark space shield) is used to collect the electrons. A similar dark space shield is used in RF diode and RF magnetron deposition, This dark space shield prevents the sides of the target and target backing plate from sputtering.

RF Sputtering-Etching

Essentially the reverse process of RF diode sputter deposition, in which the substrate table becomes the cathode (negative pole) and the target assembly becomes the anode (positive pole). Under these circumstances, surface material from the substrates is ejected. Surface impurities are ejected along with substrates material, making this process useful for pre-cleaning substrate prior to sputter deposition. In order to prevent ejected material from contaminating the target, s shutter is positioned between target and substrate.

Bias Sputter Deposition

Bias sputtering combines the DC or RF sputtering and the RF etching operations. While DC or RF power is applied to the target, a small amount of RF is also applied to the substrate table. As a result, the substrate and target are both bombarded by ions ( the substrate to a lesser extent than the target ). In many applications this process yields superior quality films than can be attained using DC or RF sputtering with grounded substrates. Bias sputtering influences the crystal structure, and tends to re-sputter trapped argon from the growing film during deposition and rearrange individual atoms of the sputtered material; this improves stoichiometry and step coverage. Bias sputtering can be used to adjust film resistivity and film stress to desired levels.

Reactive Sputtering

Some metals, such as nitrides and oxides, are best deposited by this method: the target is the parent metal and a small amount of nitrogen or oxygen is introduced into the process chamber along with the argon sputtering gas. Because ionized gases are typically highly reactive, a film deposited in a mixture of argon and a reactive gas will often form a compound with the reactive gas (e.g., a nitride or an oxide).

Co-Deposition

Sometimes called co-sputtering or dual deposition, co-deposition is identical in principle and practice to other types of sputter deposition, except that two targets (typically of different materials) are simultaneously activated. Substrates passing sequentially and repeatedly beneath the targets are coated with alternating, very thin films of two materials. Under certain circumstances, the resultant film can be equivalent to or better than one formed using a composite target. During co-deposition, both targets may be RF, both DC, or one RF and one DC.

Perkin-Elmer 4400 Sputtering Deposition Equipment Dimension