Description

Temescal FC-1800 Load Locked E-Beam Evaporator

Used. It was for 6 inch GaAs before moving to our warehouse in Morgan Hill,CA USA 95037

ID: SS380-000A-ED-20210722

Valid Time: Subject to prior sale.

Condition: We sell it at complete, working, functional test.

Price: Pls contact us.

MSP-165.4

Description of Temescal FC-1800 Loadlock E-Beam Evaporator for your reference.

Production Features

• High throughput due to fast cycling, load-lockdesign

• Better reproducibility and higher yields because of complete programmed sequencing

• Improved step coverage with 2R source-to-substrate spacing

• Single dome for lift-off processes

• Minimized EIB source and substrate heater contamination since lower chamber is isolated

• Clean, convenient operation in laminar flow hood because of low profile construction

• Canted-dome planetary fixturing possible in full capacity chamber

• Manual semiautomatic or fully automatic operation due to modular systems designs

• Multimetal deposition capability with optional sources

The load-lock fast cycle concept

In 1966, Temescal introduced the first practical fast cycle coater designed for production-scale vacuum deposition-the FC-1100 with an 11″-diameter substrate carrier. It was made possible by the development f higher-speed, more efficient pumping systems, more reliable power supplies, and rugged, dependable electron-beam sources with long-life filaments. The objectives were to free industry from dependence on a batch-type operation: to offer consistently superior coatings cycle after cycle, run after run, and to insure reproducibility. The sophisticated capability of the FC-1800 is based on the technology pioneered in development of the FC-1 100. The success of the simple concept of keeping the evaporation chamber under vacuum at all times while loading substrates in and out through an isolated load/unload chamber (or chambers) depended on the efficiency of the electron-beam source and related accessories. Temescal anticipated the demands of evaporation technology and was largely responsible for the configuration of today’s proven electron-beam sources. Many problems were solved in the years between the development of the first FC-11 00 and today’s highly sophisticated FC-1800. Most were mechanical in nature: for example. eliminating shut-downs due to flaking, developing jamb-proof internal wire feeders, replacing O-ring seals with bellows seals, protecting sealing surfaces from scattered evaporant. and creating rotating rod-fed sources for subliming materials such as chrome and silica. The problems had to be solved quickly since industrial evaporation requirements were outgrowing the bell jar. By developing the integrated equipment needed by the electronics industry, Temescal has attained a unique “total systems” responsibility in the vacuum industry. We completely assemble and rigorously test each FC-1800 prior to shipment. “Total system” performance is guaranteed by Temescal. “Total system” maintenance and service are performed by qualified Temescal service engineers. You deal with only one manufacturer – TEMESCAL-and our responsibility is complete and fixed. This, in turn. makes Temescal a one-stop source for all vacuum deposition needs from the finest bell jar systems to high-production load-lock coaters.

The FC-1800

Compact

Although the FC- 1800 occupies the same floor space as and only two-thirds the height of a conventional bell Jar of the same diameter, It produces more than twice the per-shift volume. In addition. the substrates are of a consistently higher quality. For example. it takes only

9 minutes per cycle to evaporate and deposit 10,000 angstroms of aluminum. This includes the substrate heating and cooling cycles.

Capacity

Despite its compact 20″-diameter by 11 “-deep size, the FC-1800 deposition chamber is designed to accommodate the same mechanisms and duplicate all the functions performed in a conventional bell jar. The small volume of this chamber (approximately 60 liters) can be pumped down rapidly before deposition usually in less than two minutes, utilizing the standard 30 cfm mechanical pump. This rapid pump-down is

possible because of a special gate valve. The balance of the system remains under continuous vacuum throughout the run.

Uniformity and Reproducibility

Maximum uniformity of ± 7% is a characteristic of substrates coated in the Temescal canted-dome planetary and angle-of-incidence dome. Step coverage with the canted dome is excellent. Reproducibility is outstanding because the evaporation chamber is kept under vacuum at all times and the possibility of trapped or absorbed gases is minimized. Because of the efficiency of the Temescal electron-beam sources and efficiency of the Temescal electron-beam sources and the integrity of the valve system, the material to be evaporated in this unique load-lock fast-cycle coater always remains outgassed and at its threshold of evaporating temperature. The source is never allowed to cool. and the longer the evaporation chamber remains hot and under vacuum, the cleaner the system becomes. With proper cleaning of the substrates. consistent coating reproducibility is assured.

Options

There is no need to buy more capability than is required. The basic FC-1800 load-lock fast-cycle coater includes automatic valve sequencing during pump-down and venting to atmosphere. All other steps may be conducted manually by activating switches or pushing buttons.

However, modules may be added to fully automate the FC-1800. With total automation, the operator need only load and unload substrates and start the automatic cycle. In addition to automation, options include substrate heaters, a second or multi-crucible electron-beam source for sequential or graded deposition, rate and thickness monitors, shutters, wire feeders, filament evaporation sources, and many others.

Simplicity

Simplicity of operation depends entirely on the number of options ordered. However, even In the basic manual model, a semiskilled technician can operate the FC-1800 with minimum training. In construction. the FC-1800 incorporates the best features of a bell jar. It has the same uncomplicated valve sequencing. All controls are within easy reach. Unlike the conventional bell Jar. there Is no troublesome

hoist or heavy chamber. Loading is at a comfortable height. The spring-loaded hinged lid lifts with a finger-tip touch and remains In any preset position until lowered. And because of its low profile construction. the FC-1800 fits neatly into the economical, clean environment of a freestanding laminar-flow hood.

Vacuum Chambers

The large-capacity but compact load-lock deposition chamber is 20 inches in diameter and 11 inches high. By optimum utilization of space, this chamber duplicates the coating capacity and the flexibility of a conventional bell jar, and, at the same time, can be pumped down in less than two minutes. The lid is dome-shaped and will accept a canted-dome or angle of-incidence planetary fixture. The lid is hinged and spring-loaded. The spring-tensioned hinge can be set to keep the lid open in any position desired. One viewing port is provided in the load-lock deposition chamber. The volume of this “work” chamber is approximately one-third that of a conventional bell jar, so pump down is exceptionally fast. Work may be cooled in this chamber under vacuum or under partial pressure of inert gas. The evaporation chamber, directly below the deposition chamber. is kept under high vacuum continuously. It is large enough to accommodate one or two electron beam

sources associated with wire or rod-fed crucibles, feeders, shutters and monitors. Chambers and associated hardware are made of 304 stainless steel with internal surfaces No. 4 finish, or better to reduce outgassing and to facilitate cleaning. A new, unique and extremely efficient shielding system in this chamber protects all internal components from the evaporant. This one-piece shield is in the form of an open-ended single-stepped stainless steel cylinder which is held in place with spring clips. Cleaning is exceptionally easy and fast, outside the

chamber. The spring clips are released. and the unit drops straight down and out of the system.

Valves

The valve system is very similar to that used in bell jar valve sequencing. It has a simple. direct sequence which automatically controls four valves: (1) Roughing valve. (2) Deposition chamber vent valve. (3) Foreline valve, and (4) High-vacuum gate. The high-vacuum gate also acts as a shutter prior to substrate heating and deposition. It is designed to slide out of the way during evaporation. An isolation valve above the diffusion pump allows maintenance in the evaporation chamber without having to cool and vent the diffusion pump or bring the liquid nitrogen baffle up to ambient temperature.

Pumping Systems

The standard pumping system includes a 6-inch, highspeed diffusion pump module with ultimate pressure In the 1 o-e torr range. The system includes a highvacuum gate valve. a diffusion-pump isolation valve. a liquid-nitrogen trap and a 30 elm mechanical pump. The l1qu1d-nitrogen trap and its offset reservoir are built as one unit. A top diaphragm assures positive antimigrat1on trapping of all pumping fluids. Tests conducted under adverse conditions-without liquid nitrogen-measured an available pumping speed of 900 I/S when utilizing the expanded 6-inch d1ffus1on pump. An alternate pumping system is the Cyro-Torr1 CTI 8 cryopump which can be supplied with either air- or water-cooled compressors. This model has pumping speeds of 400 I/s of water vapor.

Shutters

There is an efficient shutter system to protect against unwanted deposition. First. the high-vacuum gate acts as a shutter. Second, a shuttle ring-shaped shield exchanges place with the high-vacuum gate to protect the valve sealing surface during evaporation. Third. a small shutter covers the source until just before evaporation commences, when it swings clear, and. when evaporation stops, closes.

Planetary Fixturing

The FC-1800 is the first load-lock fast-cycle coater designed to accept planetaries-both canted-dome and flat types. The movement of the canted-dome planetary during deposition assures optimum uniformity of coating and step coverage. Using the TP-8 angle-of- incidence

dome and masking guarantees the user of high uniformity and minimum step coverage. Because of the bellows-sealed rotary drive, no leakage of contaminants into the system can occur, even during extended production runs. The consistent high quality, run-after-run, is uniquely attributable to the continuous vacuum environment in the source chamber. Together, the combination of benefits to industrial producers cannot be duplicated by any other vacuum deposition system on the market.

Substrate Heaters

Optional equipment includes substrate heaters. The design of the high-speed substrate heaters is unique and cannot be duplicated in a conventional bell jar. Because the heaters are below the gate valve. contamination resulting from high-temperature exposure to the atmosphere is minimized. Also, the cooling cycle time is reduced since the residual heat is shielded from the substrates by the closed gate valve. Heating action is extremely fast – 300°C substrate temperature is attained in less than 5 minutes. A water-cooling loop keeps the lower portion of the chamber lid cool and protects the O-ring from outgassing. The substrate heating system can be programmed into an automatic cycle. or controlled manually.

Electron-Beam Sources

One or two single or multiple-crucible Temescal 270-degree deflection electron-beam sources may tie installed for single sequential or graded deposition. They have long filament life because I0n erosion has been eliminated, and the cathode is shielded from falling particles. Each electron-beam source can be provided with a quick-acting shutter and a wire- feed mechanism. A variety of arrangements is available for resistance heated evaporation. Rate and thickness control systems can be tailored to exact requirements and coordinated with sources.

Power Supply

The standard power supply is the Temescal Model CV-8. It is rated for 8 kW at 10 kilovolts continuously, can be adjusted from 1.2 to 10 kilovolts and can be used with one or two electron-beam sources. Optionally. the Model CV-14 Temescal 14 kW. 10 kilovolt power supply is available.

Option:NE-6 Switching Power Supply (10KV, 600mA) instead of the standard power supply Temescal Model CV-8or CV-14

Cabinets and Accessories

Cabinets

A unique feature of the FC-1800 frame construction is the mounting of the roughing pump. This pump rests directly on standard shock mounts on the floor, instead of on long legs. As a result, vibration transmitted to the FC-1800 during roughing is virtually eliminated. When the system is to be moved, a maintenance person simply tightens one nut linking each end of the pump to a bracket on the frame, thus lifting

the pump slightly off the floor and joining it firmly to the sturdy frame. The frame is enclosed by removable painted steel panels. Hinged doors are on the front. Access to the interior from any direction is fast and easy. The counter top is covered with black Formica. Toe space is provided at floor level for the comfort of the operator.

Instrumentation

A compact instrumentation module, which contains all necessary controls and instrumentation for manually operated units, rests on the counter top. With fully automated units, all evaporation sequencing is contained in a 41 “-high rack that may stand on top of the cabinet or in an adjacent freestanding rack. The standard CV-8 electron-beam power supply can fit in the same freestanding rack. An optional electron-beam source power supply is the Temescal CV-14, which is housed in its own rack.

Source Viewing

Since the viewport for the evaporation source is located within the cabinet, Temescal has provided a direct viewing system. With easy-to-reach controls, the technician simply opens the protective shield over the viewing port to view the source. Clear film also protects the viewport from the evaporant. Again, with counter-top controls, the technician simply advances the roll of film to an unexposed section

after it coats up.

Maintenance

All components in the FC-1800 are easily accessible There are two ways to get into the evaporation chamber. For minor maintenance, the diffusion pump isolation valve is closed, the vacuum gate is moved aside, and the operator reaches in from the top of the counter. For cleaning and major maintenance, the entire source tray can be quickly and easily rotated outside the cabinet. Quick utility disconnects are provided. The source tray then is lowered, rotated to the front or side, and raised to counter-top height outside the cabinet.

The instrumentation module contains all necessary controls and instrumentation. It may stand on top of the cabinet or in an adjacent freestanding rack.

Specifications

Cycle Time

10 to 15 minutes for 1 μ of aluminum

Coating Uniformity

± 7% with high-speed planetary substrate fixture

Construction

All internal surfaces are polished 304 stainless steel

Deposition Chamber

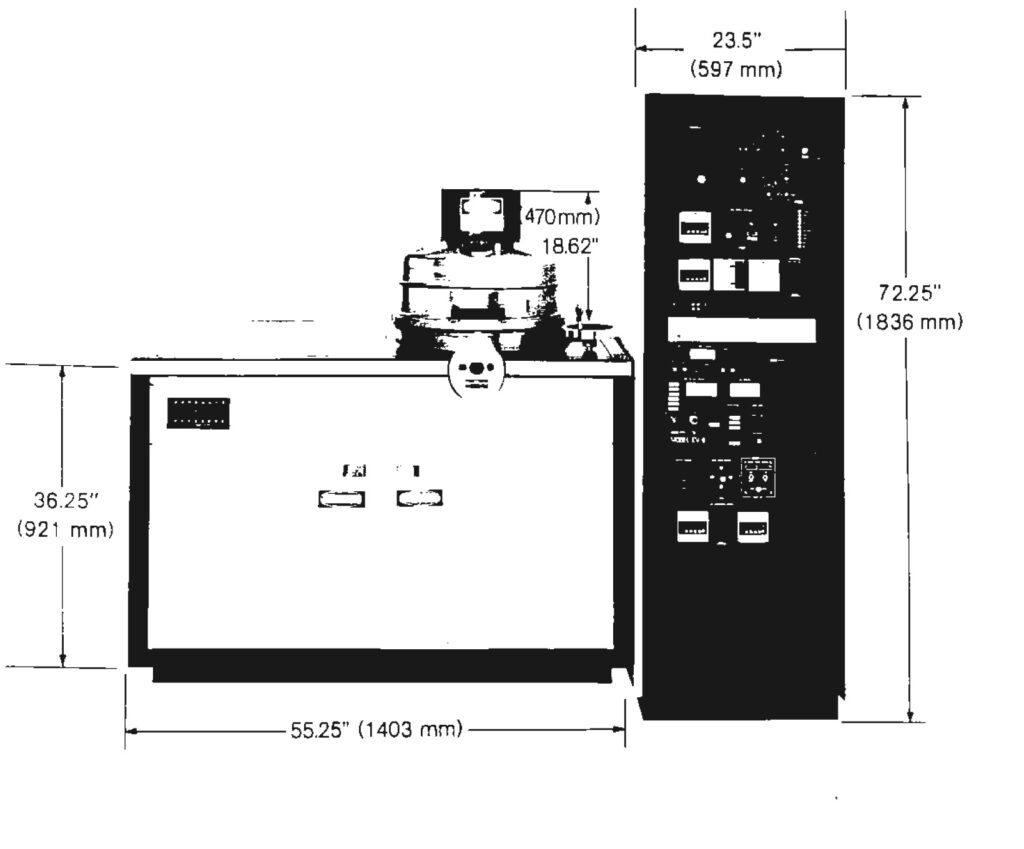

20″-diam. x 11 “-high (508 mm x 280 mm) bell jar.Designed for waist-high, 36.25” (921 mm) substrate loading and unloading. Hinged and counter-balanced cover for ease of operation. Easily raised to preset position.

Source Chamber

18″-diam. (457 mm).Automatically maintained at high vacuum at all times to prevent contamination

Source Tray

19″-diam. (483 mm) blank, flat plate.Manually operated jackscrew mechanism for raising and lowering the source tray. When lowered, the tray swings out 90° for ease of access

Electron Beam Source

A variety of optional electron beam source combinations is available (resistance sources available upon request)

Tray-mounted and fully shielded

Power Supply

A variety of 8 and 14 kW electron beam power supplies and accessories is available

Electronics

All components are conservatively rated and have proven records of performance. Electronic equipment is countertop-mounted in a 40.37″ H x 19″ W ( 1026 mm x 483 mm) relay rack for ease of operation (optional floor-supported cabinet available)

Vacuum System

Direct sequencing with automatic control of all valves. Fully automatic evaporation controller available. Vac-map panel, vacuum gauge controller and interconnecting cables provided with visual display of valving sequence and substrate rotation

Vacuum Valves

Stainless steel, removable high vacuum gate valve. Seals upward to isolate the substrate chamber from the evaporation chamber. High-vacuum valve design eliminates scuffing. Diffusion pump isolation valve for ease of maintenance.Handwheel actuated, ½” (13 mm), brass, angle leak detector valve included

Vacuum Pumps

30 cfm (845 I/m) dual-stage mechanical roughing and backing pump. Mounted on separate base for vibration isolation(remote location)

6″, 2400 I/s oil diffusion pump with isolation valve . Cryogenic pumping systems available

Shielding

Stainless steel cylindrical vapor shield in source chamber. Removable stainless steel source tray debris shield .Easily removable seal-ring vapor shield

Viewing Port

Model VV-400 4″ (102 mm) polarized-window viewing port in source chamber. Teflon® film, film advance, and shutter provided for continuous viewing

Cold Trap

Liquid nitrogen-cooled baffle

Vacuum Gauge Controller

Temescal VersaVac® ionization gauge controller with Bayard Alpert gauge tube. Automatic range-changing provided

Pumpdown Time for Load Lock

Less than 2 minutes

Typical Operating Vacuum

Mid 10-6 to mid 10-7 torr range with standard pumping system

Ultimate Operating Vacuum

1 o-8 torr with standard pumping system

Water System

Stainless steel manifold with four available circuits. Flow meter, flow switch and all necessary interconnects provided

Air System

Pressure regulator, meter and all necessary interconnects provided

Installation Requirements

Water: Filtered 1.25 gpm at 50 psig inlet pressure at <60° to 80°F (4.73I/m, 3.51 kg/cm2 , < 16° to 27°C)

Compressed air: 5 elm at 60 to 125 psig inlet pressure, filtered and dried (2360 cc/sec, 4.22 to 8.75 kg/cm2 )

Power: 208 V, 3 ct,, 70 A, 50/60 Hz, 5-wire with active neutral and equipment ground (optional input voltages available). Tolerable voltage ± 5%

Ambient temperature: 80° ± 10°F (26.8 ± 5.5°C)

Humidity: 50% maximum

Instrument weight: < 1800-lb. (818 kg)

Optional accessory utility requirements not included

Info on Temescal for your reference.

- Temescal Versatile Coating Systems

Temescal, a part of BOC Coating Technology, designs and manufactures ultra-reliable thin-film deposition equipment. Professionals prefer Temescal because, over the decades, the name Temescal has become synonymous for “absolutely, positively reliable coatings”. Temescal systems today offer conveniences such as cassette-to-cassette loading, high throughput cluster evaporation systems to handle substrates up to 1-meter x 1-meter in size. These systems offer state-of the-art control capabilities and flexibility, as well as the same • Temescal reliability. Temescal offers deposition systems to cover you, whatever your application.

• Temescal BJD-1800: Manual load, batch system, Chamber size 10 inch.

• Temescal FC-1800: Manual load, batch system, Chamber size 20 inch.

• Temescal VES-2550: Manual load, batch system, Chamber size 20 inch.

• Temescal FCE 2500: Manual load, batch system, Chamber size 20 inch.

• Temescal FCE-2700: Manual load, batch system, Chamber size 20 inch.

• Temescal FCE-3800: Manual load, batch system, Chamber size 40 inch.

• Temescal AL-3800: Operate Free, Automatic load batch system, Chamber size 40 inch.

• Temescal CE-6150: Operate Free, Automatic load cluster system, Chamber size 40 inch.

• Temescal FCE-4800: Manual load, batch system, Chamber size 50 inch.

• Temescal FCE-7000:Operate Free, Automatic load cluster system, Chamber size 50 inch. - Temescal Components Too

Temescal provides superior components as well. Making ultra-reliable coating systems requires ultra-reliable components. So Temescal makes its own. The performance of Temescal E-beam guns has become a legend in the industry- over 14,000 in operation around the world! The same is true for ultra-precise power supplies. Temescal maintains stock shelf on all the most asked-for components so you can get them faster than ever. Usually shipped within 24 hours!

Temescal designs and manufactures a wide range of deposition systems suited for a variety of semiconductor. flat panel, optical, biomedical, metallurgical and decorative applications. This versatile line includes low-profile bell jar systems, top-loading bell jar systems, fast cycle load-locked designs and cassette-to-cassette for high throughput applications. The systems range in size from a research coater with an 18-inch diameter bell jar to automatic cluster production system to handle substrates up to 1-meter by 1-meter. - Temescal Manual Load Batch Systems

Temescal Batch System

• Low Capital Cost

• High Labor Requirement

• Lowest Throughput

• 18-inch and 25.5-inch Chambers

• Up to 150 mm Substrates

Temescal Load-Lock Batch System

• Law Capital Cost

• High Labor Requirement

• Improved Throughput

• 18-inch, 25-inch, 2 7-inch and 48-inch Chambers

• Up to 300 mm Substrates - Temescal Automatic Load Batch -Systems

•Moderate Capital Cost

• Low Labor Requirement

• Improved Throughput

• Excellent Cost of Ownership

• Cassette-to-Cassette Loading

• AGV/MGV Interface

• 2 7-inch and Larger Chambers

• Up to 300 mm Substrates - Temescal Automatic Load Cluster Systems

• High Capital Cost

• Low Labor Requirement

• Highest Throughput

• Excellent Material Recovery

• Cassette-to-Cassette Loading

• AGV/MGV Interface

• 2 7-inch and Larger Chambers

• Up to I m x I m Substrates - Manual Load Batch Systems Models

Temescal BJD-1800 System

The low-profile bell jar of the BJD-1800 system permits easy access co the chamber for substrate loading. This industry-proven production system is a reliable evaporation unit for optical and electronic coating processes.

• 18-inch (45 7 mm) or 20-inch (508 mm) diameter chamber

• Clean-room compatible

• Cryopump standard; turbopump also available

• Temescal PC/PLC Control System ( optional)

Temescal VES-2550 System

Designed to provide high throughput without a load lock, the VES-2550 is suitable for all evaporation applications.

• 25.5-inch (648mm) diameter, low-profile chamber

• Designed for semiconductor production environments

• Accommodates up to three electron beam sources

• Cryopump standard; diffusion pump and turbopump also available

• Temescal/ PC/PLC Control System (optional)

Temescal FC-1800 System

The load-lock design of the FC-1800 system ensures fast-cycle production in high-throughput evaporation processes. The vacuum-isolated lower chamber reduces pump down time per cycle and minimizes source and substrate heater contamination. The low-profile bell jar design is convenient for substrate loading and for enclosure by a laminar-flow hood .

• 20-inch (508 mm) diameter product chamber

• Multiple material deposition

• Substrate fixturing for /i~-off and other process applications

• Cryopump standard; diffusion pump and turbopump also available

• Ion milling, glow discharge and substrate heat

• Temescal PC/PLC Control System (optional)

Temescal FCE-2500/FCE-2 700/FCE-3800 System

The FCE-2500 system is available either freestanding or in a clean-room-compatible, through-the-wall configuration. To optimize through-the-wall applications. both the load lock and the source tray are accessible from either the clean room or the service area.

• Accommodates multiple electron beam and resistance-heated sources

• Compatible with lift-off and variable angle processes

• Ion milling and substrate heat options available

• Manual or fully automatic operation with the

Temescal PC/PLC Control System - Temescal Automatic Load Batch Systems Models

Temescal AL SERIES

Temescal AL-3800

The AL Series systems combine the capabilities of the FCE-2700 with automatic load and unload systems for higher throughput and improved yields due to Jess handling.

• 38-inch (965 mm) or larger deposition chambers available

• Cassette-to-cassette loading

• AGV/MGV Interface standard

• Ideal for high volume production of Substrates up to 300 mm in diameter

• Throughput up to 50 substrates per hour

• Single or multiple layer deposition

• Cryopump standard; Turbo pump (optional)

• Ideal for processing 150mm GaAs substrates - Temescal Automatic Load Cluster Systems Models

Temescal CE-6 150

This automatic load evaporation system in a cluster configuration provides the highest throughput and improved cost performance available by reducing overhead and improving material recovery.

• Processes substrates up to 300 mm in diameter

• Dual vacuum cassette elevators for maximum throughput

• AGV/MGV interface standard

• Throughput up to 7 5 substrates per hour

• Single or multiple layer deposition in each module

• Total process flexibility

• Ideal for I 50 mm GaAs substrate processing

Temescal FCE-7000

The FCE-7000 evaporation system is configured so each module can deposit a single film or an entire stack, allowing for flexibility in current and future processes.

• Processes panels up to /-meter by /-meter

• High uniformity across the panel and panel-to-panel

• Automatic, sequential multi-layer thin-film deposition

• Rod-fed source ensures highest material utilization possible

• Fully automatic cassette loading and unloading

• AGV/MGV interface standard

• Coating and process flexibility allows for parallel development and production

• Ideal for FED cathode and anode evaporation processing. - Temescal Coating System Components

A wide range of components is available to support Temescal coating systems. Ongoing research and development are integral to this line of components which include:

• Electron beam sources and spare parts. CV-6S

• Electron beam power supplies

• Programmable beam sweep controllers

• Substrate fixturing

• Deposition monitors and controllers

• Feedthroughs

• High performance emitter assemblies - BOC Coating Technology is a unit of The BOC Group, the worldwide vacuum technology, industrial gases and distribution services company. Temescal is global, with agents in over fourteen countries. Call Temescal today to learn how our products can help you meet your application needs. For enabling technology .. .. nothing tops a Temescal.

Pls contact us for the availability of the following items. These are only for end users and are subject to prior sale without notice. Appreciate your time!

| 1 | 2STM-1B Temescal Metallurgical Throttle Valve |

| 2 | 4″-ST-2B Airco Temescal Vacuum Gate Valve, Quick Acting, Special |

| 3 | 4-way Skinner Electric Pneumatic Valve 115v MODEL-V935DX18 Airco Temescal 4″ |

| 4 | Airco / Temescal Model: 8008 Wired Controller. |

| 5 | Airco 1 1/2″ 2010 Brass Bellows Sealed Angle Valve Temescal 2010 Series |

| 6 | Airco 1/2″ 1010 Brass Bellows Sealed Angle Valve 1/2″ FNPT Temescal 1010 Series |

| 7 | Airco 7/8″ 1110 Brass Bellows Sealed Angle Valve Temescal 1110 Series |

| 8 | Airco CL-2A 2KW AC/DC Discharge Power Supply |

| 9 | Airco Ferrotec Temescal Four Pocket Electron Beam Source STIH270-1 E-Beam Gun |

| 10 | Airco Ferrotec Temescal Six 6 Pocket Electron Beam SuperSource E-Beam Gun |

| 11 | Airco High Vacuum Valve 1 1/2 Inch 120 VAC Fig. 2030 UHV Skinner Temescal |

| 12 | Airco Temescal 0101-8261-0 Electron Beam Power Supply CV -14 (Models A/B) Manual |

| 13 | AIRCO TEMESCAL 0918-6793-0 1000 RPM MOTOR |

| 14 | Airco Temescal 1/2″ FNPT Brass Vacuum Pump Bellows Sealed Angle Valve 1000 Serie |

| 15 | Airco Temescal 2 Inch 5010 Aluminum Valve |

| 16 | Airco Temescal 2 Inch 5010 Aluminum Valve H-82 |

| 17 | Airco Temescal 2130 1.5 inch Pneumatic Inline valve control controller 120V NICE |

| 18 | AIRCO TEMESCAL 2F4013D 2F4023 PCB BOARD |

| 19 | AIRCO Temescal 3″ 5130P ASA Vacuum Gate Valve |

| 20 | Airco Temescal 3″ Vacuum Gate Valve model 5710 |

| 21 | Airco Temescal 3” ST-2 High Vacuum Gate Valve |

| 22 | AIRCO TEMESCAL 307-2783 PCB BOARD |

| 23 | AIRCO TEMESCAL 4073983 4074003 CAPACITOR FOCUS BOARD |

| 24 | AIRCO TEMESCAL 4073983 4074003 CAPACITOR FOCUS BOARD |

| 25 | Airco Temescal 407-3983 Capacitor Focus Board Assembly Plug-In Module 407-3993 |

| 26 | Airco Temescal 5/8″ Stainless Steel Vacuum Angle ValvePING |

| 27 | Airco Temescal 5130 4″ Gate Valve Varian VSEA 5860001 Manufacturer |

| 28 | AIRCO TEMESCAL 5730-R 3″ VACUUM GATE VALVE |

| 29 | Airco Temescal 6″ FIG 5030 Gate Valve EXCELLENT |

| 30 | Airco Temescal 6″ Fig. 5530 Vacuum Gate Valve, 8 Bolt Holes, w/ Micro Switch |

| 31 | Airco Temescal 702-4453 1″ Baseplate Three-pass Gas/Liquid Feedthrough |

| 32 | Airco Temescal 7766 2 Inch Aluminum Gate Valve Fig 5010 |

| 33 | AIRCO TEMESCAL 8008 HAND HELD CONTROLLER |

| 34 | Airco Temescal AGC-2000 Laboratory Auxiliary Gauge Control 2U |

| 35 | AIRCO TEMESCAL Auto Pump Down Control |

| 36 | Airco Temescal Auto Sequence Control |

| 37 | AIRCO TEMESCAL AUTO SEQUENCE CONTROLLER |

| 38 | AIRCO TEMESCAL AUTO SEQUENCE CONTROLLER |

| 39 | Airco Temescal BR-IF Bellows-Sealed Rotary Feedthrough |

| 40 | Airco Temescal CV-14 E-Beam Electron Beam Power Supply CV14 |

| 41 | Airco Temescal CV-14 Electron Gun Control D.C. AMPERES |

| 42 | Airco Temescal CV-14 High Voltage Control D.C. AMPERES |

| 43 | AIRCO TEMESCAL CV8 POWER SUPPLY |

| 44 | Airco Temescal CV-8 Power Supply Station CV8-2587 – Missing Tube |

| 45 | AIRCO TEMESCAL CV-8, CV8A-212 E.B.POWER SUPPLY |

| 46 | Airco Temescal CV-8-110 Electron Beam Power Supply |

| 47 | Airco Temescal CV-8-2666 Power Supply For FC-1800 Evaporator ID-D380power-001 |

| 48 | Airco Temescal CV-8A-110 Industrial EB Power Supply Unit 5U Rackmount |

| 49 | Airco Temescal FC-1800 Controller ID-D-EV001-2 |

| 50 | Airco Temescal FC-1800 CV-8 High Voltage Control ID-D-EV001-7 |

| 51 | Airco Temescal FC-1800 CV-8 High Voltage Control ID-D-TRACK-2-001 |

| 52 | Airco Temescal FC-1800 Evaporator |

| 53 | Airco Temescal FC-1800 Gun Control 1 ID-D-EV001-8 |

| 54 | Airco Temescal FC-1800 Gun Control 1 ID-D-TRACK-2-002 |

| 55 | Airco Temescal FC-1800 Inficon IC 6000 ID-D-TRACK-2-003 |

| 56 | Airco Temescal FC-1800 Inficon IC/5 Deposition Controller ID-D-EV001-3 |

| 57 | Airco Temescal FC-1800 Leak Check Sensitivity Varian ID-D-EV001-12 |

| 58 | Airco Temescal FC-1800 Manual Vale Control ID-D-EV001-10 |

| 59 | Airco Temescal FC-1800 MKS HPS Products 937A Gauge Controller ID-D-TRACK-2-007 |

| 60 | Airco Temescal FC-1800 Shutter Control Boc Coating Technology ID-D-EV001-9 |

| 61 | Airco Temescal FC-1800 Substrate Heat ID-D-EV001-11 |

| 62 | Airco Temescal FC-1800 Varian 843 Vacuum Ionization Gauge ID-D-TRACK-2-006 |

| 63 | Airco Temescal FC-1800 Varian Accessory Control ID-D-TRACK-2-005 |

| 64 | Airco Temescal FC-1800 Varian Vacuum Process Control 980-6100 ID-D-TRACK-2-004 |

| 65 | AIRCO TEMESCAL Film Deposition Controller FDC-8000 |

| 66 | AIRCO TEMESCAL HRS 2550 SPUTTERING SYSTEM |

| 67 | Airco Temescal Metallurgic Manual Valve Gate 9″ OD 5.25″ ID – 4″ |

| 68 | Airco Temescal model 8008 hand held controller |

| 69 | Airco Temescal Model CV-8 Power Supply |

| 70 | AIRCO TEMESCAL MODEL MC4 VACUUM CONTROL,MC-4B,A/M VACUUM CONT BJD-1800 |

| 71 | AIRCO TEMESCAL PROPORTIONAL SUBSTRATE HEAT,EUROTHERM 917/PAP |

| 72 | Airco Temescal Right Angle Valve Regulator |

| 73 | AIRCO TEMESCAL SC-8009 0506-7160-0 CRYSTAL SENSOR |

| 74 | AIRCO TEMESCAL SC-8009 0506-7160-0 CRYSTAL SENSOR |

| 75 | Airco Temescal SSC-150 Turbomolecular Vacuum Pump Frequ |

| 76 | Airco Temescal VACUUM Technology. MOD MAIN. ASSY 0504-2330-0 |

| 77 | AIRCO TEMESCAL VACUUM WATERLINE FEEDTHROUGH 1 INCH FOR HIGH VAC EVAPORATOR |

| 78 | AIRCO TEMESCAL VERSA VAC 2 VERSAVAC 2 THERMOCOUPLE IONIZATION GAUGE PARTS |

| 79 | AIRCO TEMESCAL VERSAVAC 2. Key not included.ping. |

| 80 | AIRCO TEMESCAL VERSAVAC 5 |

| 81 | AIRCO TEMESCAL VERSAVAC 511-0323B 511-0343 RELAY OUTPUT MODULE |

| 82 | Airco Temescal XY Sweep BOC Coating Technology Programmable Sweep 0040-1054-2 |

| 83 | AIRCO Temescal XYS-8-1A Sweep Control |

| 84 | AIRCO Temescal XYS-8-1A Sweep Control |

| 85 | AIRCO TEMESCAL XYS-8-2A SWEEP CONTROL |

| 86 | AIRCO VERSAVAC TEMESCAL 511-0313 ELECTROMETER PC BOARD |

| 87 | Arleen C Temescal Fabric Flat Thong Sandals Rhinestone, Size 7 M Gray Shimmer |

| 88 | Black screened 2014 IDM wrestling tourn T shirt 5th annual Temescal Canyon High |

| 89 | BOC Coating Technology 9999-8092-0 Temescal Spare Replacement Contact |

| 90 | BOC Edwards Temescal 0620-9120-0 Cable Assy SS64 Sweep Coil Dr. |

| 91 | BOC EDWARDS TEMESCAL SIMBA 2 Electron Beam Power Supply, |

| 92 | BOC Edwards Temescal SuperSweep64™ Digital E-Beam Sweeper Rack Mounting |

| 93 | BOC TEMESCAL 6042 2508 0 Din Rail Mount Adapter |

| 94 | BUTTERFLY VALVE, ALUMINUM, AIRCO TEMESCAL 2″ ST-1, MANUAL TURN |

| 95 | CHA / Temescal Evaporator Shielding Schematics Manual |

| 96 | CVC Power Supply For Temescal FC-1800 Evaporator DP-4-2 |

| 97 | E-Beam Vacuum Coating, Temescal VES-2550, Semiconductor Lab Equipment |

| 98 | Edwards Temescal 0040-1054-2 EB Scanner 1 Phase Programmable XY Sweep Scanner |

| 99 | Edwards Temescal 0040-1054-2 EB Scanner 1 Phase Programmable XY Sweep Scanner |

| 100 | EDWARDS TEMESCAL EB PWR SPLY SIMBA GUN INTERFACE PART 0040-3620-0 MODEL SIMBA 2 |

| 101 | Edwards/Temescal VES-2550 E-Beam Evaporator 3-Phase 208V CV-6SLX (6024-7110-0) |

| 102 | FC-1800 CTI-CRYOGENICS Cryopump Relief Valve Filter PN 8044112 . ID-DQ-1-1-007 |

| 103 | FC-1800 Evaporator Parts In A Lot . ID-DQ-1-1-006 |

| 104 | FC-1800 Evaporator Shuttle ? Shields? Shielding . ID-DQ-1-1-005 |

| 105 | Ferrotec -Temescal Electron Beam Source, 4 pocket. E-Beam 270-3CKB |

| 106 | Glen Ivy Temescal Valley 1964 Feasibility Study Riverside County History |

| 107 | GP270 Gauge Controller Granville-Phillips Airco Temescal FC-1800. ID-D-EV001-1 |

| 108 | Inficon Airco Temescal 15528 Spectrometer Tube 2130-CT |

| 109 | Liquid Nitrogen LN2 Bottle 531-13 00004986-000 Was For Hitachi CD-SEM ID-DW-6-5 |

| 110 | MBE vapor source UHV vacuum deposition conflat temescal mocvd mdc varian |

| 111 | PELECTRON BEAM EVAPARATOR OWER CONTROL BY AIRCO TEMESCAL MODEL SCR-4 0505-0210 |

| 112 | Pipe Heat WCSH-0120-0000 105.0 0920c37-50144 E43684 HPS 4525-0017 A ID-DQ-2 |

| 113 | Stainless Steel Adaptor ISO-100-CF 4-5/8 PN P103833 ID-DZ-7-004 |

| 114 | Stainless Steel Flange 4”/6” ? ID-DZ-7-005 |

| 115 | Stainless Steel Flange 5.5” /7” ID-DZ-7-002 |

| 116 | Stainless Steel Flange 6” /11”-7” ? ID-DZ-7-003 |

| 117 | Stainless Steel Flange 8”/10” ? ID-DZ-7-001 |

| 118 | Temescal 2″ Vacuum Gate Valve |

| 119 | TEMESCAL “SuperSource” 6 POCKET E-BEAM SOURCE (GUN), VERY CLEAN |

| 120 | Temescal 0040-3563-0 Position Control PCB PLC Card Board |

| 121 | Temescal 0101-8261-3 Electron Beam Power Supply CV-14 Models A & B Manual |

| 122 | Temescal 0101-8572-2 Model FCS-3200 Fast-Cycle Load-Lock Sputter System Manual |

| 123 | Temescal 0101-8572-2 Model FCS-3200 FastCycle Load-Lock Sputtering System Manual |

| 124 | Temescal 0101-8575-7 FC-1800#321 Documentation Service Manual |

| 125 | Temescal 0101-8741-0 HA-2 1KW Substrate Heating Assembly Instruction Manual |

| 126 | Temescal 0101-9009-0 FCE-2500/2700 System Documentation Service Manual |

| 127 | Temescal 0222-9232-0 Wheel Bushing |

| 128 | Temescal 0224-2611-0 2″ 5130 Vacuum Gate Valve *FREE SHIPPING* |

| 129 | Temescal 0317-6871-0 Filament Replacement 7 1/2 Turns Qty 2 NOS |

| 130 | Temescal 040-3543A Position Control PCB PLC Card Board |

| 131 | TEMESCAL 0511-0664-0 ROTATION CONTROLLER |

| 132 | Temescal 0620-7612-0 Cable , EBC Indexer DR For Thin Film Deposition Equipment |

| 133 | Temescal 0629-0364-0 Assembly , TRC Drive, UPG , New, Never Used |

| 134 | TEMESCAL 0715-8173-2 INSERT, NEW *QTY 2* |

| 135 | Temescal 101-0481 BCD-2430 Ion Plater With Rod Fed Source Instruction Manual |

| 136 | Temescal 2″ Vacuum Gate Valve |

| 137 | TEMESCAL 200 LASER CONTROLLER POWER SUPPLY |

| 138 | Temescal 2130 SS 5/8″ Vacuum Valve w/120 VAC Skinner Solenoid Air Valve |

| 139 | TEMESCAL 3497 GATE VALVE 8 3/4″ OUTER DIAMETER CAT NO 4″ 5130P |

| 140 | Temescal 3CK Crucible |

| 141 | Temescal 7cc Premium Poco Graphite Crucible/Liner 9998-9004-0 for Ebeam Gun |

| 142 | Temescal 9-20-97 FCE-2500/2700 System Documentation Operations Manual |

| 143 | Temescal Airco ASC-3200S Control Panel *for parts* |

| 144 | Temescal Airco ASC-3200S Control Panel *sold , for parts* |

| 145 | Temescal Airco ASC-3200S Process Status Control Panel *for parts* |

| 146 | Temescal Airco ASC-3200S Status Control Panel *untested, being sold * |

| 147 | TEMESCAL AIRCO E.B. POWER SUPPY CV-8A-111 |

| 148 | Temescal Airco Motorola M68MM01 Micromodule 1 Computer Module *New Surplus* |

| 149 | Temescal Airco RSC-1000 Rotation Sequence Controller *for parts* |

| 150 | Temescal Airco RSC-1000 Rotation Sequence Controller *sold * |

| 151 | Temescal Airco RSC-1000 Rotation Sequence Controller *sold , for parts* |

| 152 | Temescal Airco SC-3200 Sputtering Controller ***new surplus, 90 day warranty**** |

| 153 | Temescal Airco SC-3200 Sputtering Controller *new surplus, 90 day warranty* |

| 154 | TEMESCAL AUTO SEQUENCE CONTROL |

| 155 | TEMESCAL AUTO SEQUENCE CONTROL |

| 156 | TEMESCAL AUTOMATIC REGENERATION CONTROLLER ARC-2000 |

| 157 | Temescal Auxiliary Control Panel Display A/W 610-7994 FAB 610-8004 ASSY 610-8014 |

| 158 | Temescal BJD 1800 Thermal Evaporator – Co-Deposition – Refurbished – Warranty |

| 159 | Temescal BJD 1800 Vacuum System |

| 160 | Temescal BJD-1800 3-Cathode Sputter System |

| 161 | Temescal BJD-1800 BOX COATER with 8 Thermal Evaporation Sources |

| 162 | Temescal BJD-1800 E Beam Evaporator Instruction Manual |

| 163 | Temescal BJD-1800 E-Beam Vacuum Deposition Evaporator Tag #86 |

| 164 | Temescal BJD-1800 Evaporator |

| 165 | TEMESCAL BJD-1800 REBUILT |

| 166 | TEMESCAL BOC COATING TECHNOLOGY CV-6S ELECTRON BEAM POWER SUPPLY 6KW 6024-6002-0 |

| 167 | Temescal BOC Coating Technology TRC-3460 Pocket Selection |

| 168 | Temescal BOC SuperSweep 64 |

| 169 | Temescal Cable Assembly HV 4′ FPS-SRC, SATIS P/N 0620-8674-0 |

| 170 | Temescal Cables EBC-HVPIOTS 0620-6824-0 |

| 171 | Temescal Canyon Assembly Camp PACIFIC PALISADES Los Angeles Antique Chautauqua |

| 172 | Temescal CV-14 Constant Voltage Power Supply Manual |

| 173 | Temescal CV15 Power Supply With Computer Interface Manual |

| 174 | TEMESCAL CV-6SL / CV6SL (REPAIR EVALUATION ONLY) |

| 175 | Temescal CV6SL 13945 3 Phase, 20 A, 400V, 6000W Electron Beam Power Supply |

| 176 | Temescal Electron Beam Power Supply and Gun Controller |

| 177 | Temescal FC-1800 BOC Coating Technology TRC-3460 Pocket Select ID-EV001-3 |

| 178 | Temescal FC-1800 Component Manuals Manual |

| 179 | Temescal FC1800 E Beam Evaporator |

| 180 | Temescal FC-1800 Electron Beam Evaporator System – TES refurbished and upgra |

| 181 | Temescal FC-1800 Evaporator |

| 182 | Temescal FC-1800 Evaporator |

| 183 | Temescal FC-1800 Evaporator Shielding shield. ID-DQ-1-1-001 |

| 184 | Temescal FC-1800 Evaporator Shielding shield. ID-DQ-1-1-002 |

| 185 | Temescal FC-1800 Evaportation System Instruction Manual |

| 186 | Temescal FCE-1800 Manual Electron Beam Evaporator System Manual |

| 187 | Temescal FCE-2700 Electrical Component Manuals Manual |

| 188 | Temescal FCE-2700 Volume III Spares, Drawings With Parts Lists Manual |

| 189 | Temescal FCS-3200 Electrical Prints & Modifications Manual |

| 190 | Temescal FCS-3200 Evaporation System Instruction Manual |

| 191 | TEMESCAL GATE VALVE 3″ 5130 V-5 |

| 192 | Temescal HV and Gun Control for Simba II Power Supply |

| 193 | Temescal IG-1300 Thermocouple Ion Gauge – |

| 194 | Temescal Ion Gauge Tube 924B |

| 195 | TEMESCAL LEGACIES: NARRATIVES OF CHANGE FROM A NORTH By Jeff Norman |

| 196 | Temescal Magnet Rotary Feedthrough 9999-0014-1 B81427 |

| 197 | Temescal Model BJE2400 Automatic R-F Sputter ETCH System Manual |

| 198 | Temescal Model FDC 8000-1 FDC 8000-2 Film Deposition Controller Manual |

| 199 | Temescal Model: 2030. 1-1/2″ Valve. |

| 200 | Temescal Power Supply 15VDC 5VDC 24VDC 2A 7A 1A |

| 201 | TEMESCAL PROPORTIONAL SUBSTRATE HEAT |

| 202 | Temescal SFIH270-2 Super Source Bar Magnet |

| 203 | Temescal Simba 0611-7344 Gun Interface Electron Beam Sources Power Supply – USA |

| 204 | Temescal Simba 2 Electron Beam Power Supply 0611-7330, Three Phase, 15 kW – USA |

| 205 | Temescal Simba 2 Electron Beam Power Supply, input: 480V |

| 206 | Temescal SIMBA 2 Gun Interface Power Supply 0040-6720-3 |

| 207 | Temescal Simba Gun Interface 0611-7344-2 Electron Beam Power Supply, Made in USA |

| 208 | Temescal Simba Gun Interface STMBA 2 0040-6720-1 |

| 209 | Temescal Simba II Gun Control Driver board |

| 210 | Temescal Sloan Telemark Style Electron-Beam Feedthrough |

| 211 | Temescal STIH-270-2CK/2CKB Super Source 2 Electron Beam Turret Source Manual |

| 212 | Temescal Supersweep64 / Excellent / 4 month warranty / Late Model / Last One |

| 213 | Temescal Technical Engineering Services (T.E.S.) FC-1800 Load Locked E-Beam |

| 214 | TEMESCAL TELEGRAPH NEW CD |

| 215 | TEMESCAL TURRET SOURCE SELECTOR |

| 216 | TEMESCAL VALLEY CA California Short-Sleeve Unisex T-Shirt |

| 217 | TEMESCAL VALLEY CA California Short-Sleeve Unisex T-Shirt |

| 218 | Temescal Versavac-2 Ion gauge control. 2 Units For Sale |

| 219 | Temescal VES 2550 Electron Beam Evaporator with warranty |

| 220 | Temescal VES 2550 Rebuilt Vacuum System |

| 221 | Temescal VWS1090 Sweep / BOC Coating / Ebeam Sweep control / warranty |

| 222 | Temescal, BOC / EB PWR SUPPLY, 0611-7344-0 / SIMBA GUN INTERFACEO |

| 223 | TEMESCAL,1920 s,H.H.Knibbs,DJ |

| 224 | Temescal/Airco FC-1800 E-Beam Thin Film Evaporator w/1 Gun |

| 225 | Vacuum valve 4 in ID Temescal Metallurgical Corp |

SS-OEM-00-20220412