Description

Model: Perkin-Elmer 4400

Category: Sputter

Original Equipment Manufacturer: Perkin-Elmer

Condition: Used. We sell them at complete, working, functional test with OEM specifications and the following customized configuration.

- DC magnetron Sputter, RF Diode Sputter, RF magnetron Sputter

- 1-4 of cathode.

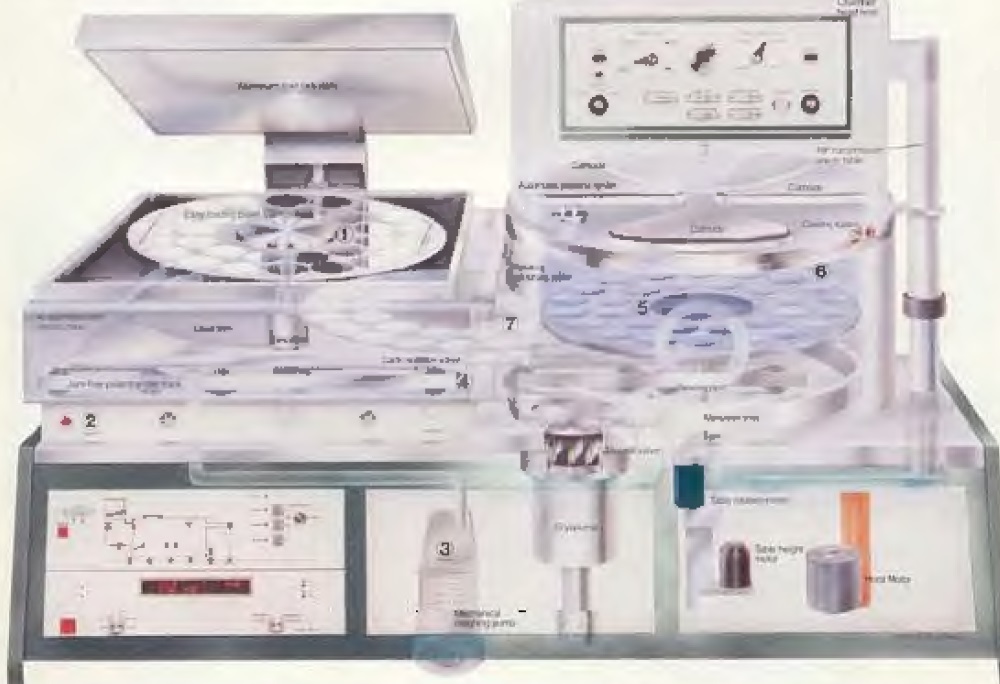

Perkin-Elmer 4400 Sputtering Deposition Equipment Delta Cathode

- small sample to 6 inch wafer

- 1-2 gas lines with MFC

- RF Etch

- Bias function

- Loadlock heating function

- Chamber heating function (Occupy one cathode port).

- Co-Sputter function

- Reactive sputter function

Price: Please contact us

Quantity: 4

Valid Time: Subject to prior sale without notice

Lead Time: TBD

Location: U.S.A.

Warranty: 3 to 9 months.

erkin-Elmer 4400, Perkin-Elmer 4410, Perkin-Elmer 4450,Perkin-Elmer 4480, Perkin-Elmer 2400, Perkin Elmer 4400, Perkin Elmer 4410, Perkin Elmer 4450,Perkin Elmer 4480, Perkin Elmer 2400, Sputter, Magnetron Sputter, Diode Sputter, DC Sputter, RF Sputter, DC Magnetron Sputter, RF Magnetron Sputter, Co-sputter, Reactive Sputter, MRC, MRC 603, MRC 903, MRC 602, MRC 902, MRC 604, MRC 904, MRC 924, Plasma Etch, Dry Clean, Bias Function, Cathode, Load lock, Degas, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment,, Thin Film, Metal Thin Film, Thin Film Deposition, PVD, Physical Vapor Deposition

Perkin-Elmer Sputter System Information for your reference only.

As new commercial and industrial technologies emerged and grew, so did the use of sputtering as a technique for deposition thin films of desired characteristics. The Perkin Elmer 4400 and Perkin Elmer 2400 Series sputtering systems were designed to meet the changes of this changing technical environment, whether in development or production.

With an installed base of more than thousands of systems, Perkin-Elmer was a leading supplier of sputter deposition equipment for high technology application in 1990’s. The Perkin Elmer 2400 Series sputtering systems were used not only in the production of semiconductor devices but also in the development and manufacturing of thin film recording heads, thin film resistors and capacitors, optical coatings, gallium arsenide lasers and fiber optics.

Quality, performance and stability backed by more than two decades of experience in vacuum technology and UHV design were built into every Perkin Elmer sputtering system. The Perkin-Elmer4400 and Perkin-Elmer 2400 Series were designed for flexibility offering a wide range of operating and process modes. The highest quality construction and components assure reliable operation and an ultra clean vacuum environment to yield consistently reproducible results. Every Perkin Elmer sputtering system was supported by years of technological experience and backed by a worldwide sales and service organization dedicated to prompt courteous service.

The Perkin Elmer4400 and Perkin Elmer2400 Series of sputtering systems represent just one part of the Perkin Elmer Semiconductor Equipment Group’s unique “one source” approach to cost-effective VLSI production. From mask making to photolithography, dry etching and sputtering deposition, the Semiconductor Equipment Group provides an integrated line of performance-proven production equipment specially designed to address each critical process. This “one source” solutions designed to meet the semiconductor industry’s demands throughout the 1980’s.

Versatile Systems For Any Sputtering Need

The Perkin Elmer 4400 Series, designed specially for high throughput production environments, features a high capacity load lock and a broad range of operating models to accommodate virtually any thin film coating requirement.

- High Throughput

The Perkin-Elmer4400 Series fast cycle load lock, cryogenic pump, and full flood Meissner trap ensures quick turnaround on batch loads. High throughput are achieved for a full range of substrate sizes and shapes.

- High Yield

A rotating substrate table for multi-pass deposition helps assure high uniformity and run-to-run repeatability. Simplicity of mechanical design with a minimum number of moving parts in the process chamber minimizes the generation of defect-causing. Easy loading pallet designs reduce wafer breakage. Consistently clean vacuum conditions assure reproducible high quality films.

- Optimum Process Control

The Perkin-Elmer4400 Series provides a broad choice of target materials, machine operating models, pressure and gas controls, cathode configurations and power levels. Operating models include DC magnetron, RF magnetron, RF diode, bias sputter, reactive sputter, co-sputter and RF etch.

- Total Control of Critical Film Characteristics

The Perkin-Elmer 4400 Series systems yield excellent films for a wide variety of materials including aluminum alloys, platinum silicide, titanium-tungsten, nichrome-gold, silicon nitride, silicon dioxide, precious metals and permalloy.

Deposition Of Thin Film for VLSI Geometries

Perkin-Elmer 4400 Series System configurations

No single cathode design can effectively meet the varied needs of different users or even the possible multiple needs of one user. Every film requires an optimum combination of target material, size, and shape for its most efficient fabrication. Recognizing these realities, the Perkin Elmer 4400 Series provides two distinct cathode configurations: 8″ circular and delta-shaped.

- Perkin Elmer 4400

A general purpose sputtering system employing up to three 8″ diameter circular cathodes in DC magnetron, RF magnetron, or RF diode configurations. Power options are available up to 2 kw RF and 5 kw DC.

- Perkin Elmer 4410

A delta target sputtering system designed for high rate deposition of metals and metal alloys. The Perkin Elmer4410 is also adaptable to the deposition of dielectrics and employs up to three delta-shaped cathodes in DC magnetron, RF magnetron, or RF diode configuration. Power options are available up to 3 kw RF and 10 KW DC.

- Perkin Elmer 4450

A delta target sputtering system, similar to the Model Perkin Elmer4450 with load lock pumping and heating incorporated as standard features.

- Perkin Elmer 4480

A delta target sputtering system of identical design to Model 4480 but including cassette-to-cassette loading as a standard feature.

As VLSI geometries routinely approach the one to two micron region, new problems arise in thin film deposition technology, dry etched vertical walls, deep vias and multiple level structures must all be uniformly covered with no microcracks or cusping. Film deposition systems must be able to provide uniform conformal coverage of these tightly packed structures to minimize interconnect resistances and maximize yields.

Substrate heating has improved step coverage of LSI structures by increasing the surface mobility of the depositing atoms. Additional techniques are now being used to further enhance coverage of planar-magnetron-sputtered films. Perkin Elmer 4400 and Perkin Elmer 2400 Series sputtering systems utilize “multi-pass” design and RF bias to maximize film coverage of VLSI structures.

As geometrical features get smaller, new materials will be employed. Metallization layers now include the use of diffusion barriers and low resistance gate and interconnect materials such as refractory metal silicides.

Substrate Motion

By utilizing rotating substrate table, Perkin Elmer sputtering systems allow wafers to be coated by multiple passes through the target region. This technique can minimize shadowing effects sometimes encountered in the single pass mode or center-to-edge effects found in static deposition systems, while maximizing target material utilization, step coverage and device yield.

RF Bias

The application of RF bias to the substrate re-sputters deposited material from horizontal surfaces onto the surrounding vertical walls of the wafer. Step coverage of 50% or more can be achieved on vertical steps and deep vias can be uniformity covered with RF bias and multi-pass technologies.

Co-sputtering

The deposition of contamination-free, low-resistance refractory metal silicides request the use of the purest materials. Co-sputtering provides the optimum method for depositing these films from pure elemental targets, wile providing a convenient means to control the stoichiometry of the films. Oxygen and carbon contamination and target-to-target stoichiometric non-uniformities are minimized using dual target sputtering and multi-pass techniques.

High Vacuum Technology for Maximum Process Control

- Fast Cycle Load Lock Operation

The Perkin Elmer 4400 Series high capacity load lock system eliminates the need to break vacuum; thereby reducing both pumpdown time and contamination of targets and internal chamber surfaces. Transfer of a full pallet load of wafers from air to the process chamber and pumpdown to a base pressure of 5X10-7 Torr can be accomplished in less than 3.5 minutes.

- Contamination-free Cryogenic Pump

The process chamber vacuum system incorporates a contamination-free, closed cycle, two-stage helium cryopump (turbomolecular pump optional). Under load conditions, 70oK is maintained in the first stage and less than 15oK in the second stage. This assures efficient, rapid pumping of most atmospheric gases and reduction of partial pressures of most unwanted gas species to acceptable levels. An ultimate vacuum of 10-6 scale can be attained with typical pumping speeds of 1000 l/s for nitrogen, 1100 l/s for hydrogen and 4200 l/s for water vapor.

- The Meissner Trap

A full flood Meissner trap mounted in the process chamber maintains an efficient pumping speed for water vapor of 30,000 l/s during deposition or sputter etching. The Meissner trap pumps water vapor at a maximum rate even with the high vacuum cryopump throttled. This assures good quality films in critical processes such as the deposition of aluminum alloys.

- Substrate Degassing

The Perkin Elmer 4400 Series systems can be equipment with load lock heating and turbomolecular pumping to degas substrates prior to processing and minimize pumpdown for critical processes such as the deposition of aluminum alloys and other oxidizable metals. This further reduces the partial pressure of undesirable gases such as water vapor.

- Vacuum Control

All Perkin-Elmer 4400 Series systems are equipped with ion and thermocouple gauges. A wide-range gauge controller monitors and digitally displays vacuum levels from 10-11 to 200 microns providing continuous monitoring of operating pressure. Additional thermocouples provide inputs to the automatic pumpdown control and automatic lock control.

The Circular Cathode Systems-Model 4400

Model 4400 is designed for use in production environments or process development. Up to three 8-inch circular cathodes and a 350oC quartz lamp heater may be installed in the process chamber to accommodate a variety of processes. An optional RF power sputtering network enables the RF/RF Co-deposition of two different materials. Precise stoichiometries of graded interface may be easily achieved.

The Model 4400 is routinely used for such processes as the deposition of Cr-Co for recording discs, Cr-Cu for backside metallization, TaSi2 for gate metallization and Si3N4 for interlayer dielectric.

Chrome-Cobalt

A precise ratio of chrome to cobalt is readily achieved with co-deposition using the RF power splitting option, ideal film temperature in the range 170 oC-200 oC can be easily obtained for optimum grain growth and orientation.

Chrome-Gold

The films resulting from the sputter deposition of chrome-gold are superior to those obtained from evaporation processes, pre-etching prior to deposition removes native oxide improving film adhesion and RF magnetron deposition results in lower thin film temperature and less gold interdiffusion.

Tantalum Silicide

Tantalum silicide of any desired stoichiometry is easily deposited with co-sputtering using the RF power splitting module. Annealed film resistivity of approximately 2.3 ohms per square can be obtained from a typical 2000 angstrom film of tantalum silicide. Within further advances in process technology, the UHV design of the 4400 will enable it to accommodate the deposition of refractory metal silicide films of even higher resistivities.

Silicon Nitride

With RF bias deposition, silicon nitride films exhibiting low pin-whole count, good step coverage and low stress can be readily deposited in the model 4400.

The RF Power Split Module

The two-way adjustable RF Power Split Module provides precise control of the level and ratio of RF energy from a single RF generator to two 8″ diameter cathodes simultaneously. A total of 2 kw may be applied with power ratio adjustable between 5% and 95%. This module is idea for use with the Model 4400 and 2400-8SA in R&D and in low volume production applications, where precise control of alloying of film properties is desired.

Features

- Efficient 8″ round cathodes

- High throughput operation

- High Uniformity

- DC, RF Etch and Bias operation

- Ultra Clean vacuum system

- Load lock operation

- UHV design

- Flexible for development or production use

- Substrates up to 6″ diameter

- Various pumping and power options

- RF/RF co-sputtering option

- Optional gas controllers

A Wide Range of Process

The following processes have been demonstrated in the Model 4400

| Al+W | Cr/SiO2 | SiC | Ti+Au |

| Al+Ti/W+Ag | InSnO | SiO2 | Ti+Au+Ni |

| Al2O3 | Mo | SiO2+O2 | Ti/W |

| Ag | MoSi2 | Si+N2(Si3N4) | Ti/W+Au |

| Au | Mo2Si5 | Si+N2+B4C | Ti/W+Au+Ta |

| C | Mo5Si3 | Ta | Ti/W+Al/Si |

| Cr | Ni | TaC | Ti/W+Ni/Cr+Au |

| Cr/Co | Ni/Cr | Ta+Au | Ti/W+Pt |

| Cr/Au | Ni+Ni/Cr | TaSi2 | W |

| Cr+Cu | Ni/Fe | Ta+SiO2 | W+Al2O3 |

| Cr/Si | Ni/Fe+Cu+SiO2 | TiO2 | Zn |

| Cr/SiO | Pt | TiO2+Cr | ZnO2 |

| Zr |

Aluminum Alloy Sputtering

The Perkin Elmer Delta cathode systems(Model 4410, 4450, 4480) are ideally suited to aluminum alloy deposition for gate contact and interconnect metalization.

- Utilization and Rate

A Delta cathode system achieves an instantaneous deposition rate for aluminum alloys of 12,000 angstroms/minute. The substrate pallet can be in excess of 200 angstroms/kw minute with sputtered material utilization approaching.

- Uniformity and throughput

Delta cathode systems maximize uniformity of deposition, exhibiting a +/-7% uniformity over a 6″ annular width. Optional high performance Delta cathodes yield a uniformity of +/-5% over a 73/4 inch band, allowing processing of up to 22 100mm wafers per cycle. Standard Delta cathodes process 50-60 100mm wafers per hour while optional high performance Delta cathodes yield throughput in excess of 80 100mm wafers per hour.

A particular advantage of a circular batch sputtering system is its adaptability to different substrate sizes. The Model 4410 and other delta cathode systems can easily handle substrate size up to 8 inches in diameter. Standard wafer size of 3 inch, 100mm, 125mm and 150mm can easily be accommodated.

| TYPICAL CAPACITY-UNIFORMITY DATA | |||

| Wafer Size | Loading Capacity | Deposition Uniformity | |

| Std Delta | High Perf. Delta | ||

| 3inch | 30 | +/-7% | +/-5% |

| 100mm | 22 | N/A | +/-5% |

| 14 | +/-7% | +/-4% | |

| 13 | +/-5% | +/-4% | |

| 125mm | 10 | +/-7% | +/-5% |

| 9 | +/-4% | +/-4% | |

| 150mm | 8 | +/-12% | +/-5% |

| 7 | +/-7% | +/-4% | |

| 8inch | 5 | +/-14% | +/-7% |

The Delta Cathode Systems-4410/4450 And 4480

- Resistivity

Perkin Elmer sputtering systems ensure low film resistivity by minimizing partial pressure of oxygen and nitrogen below 1X10-7 Torr. With total system background pressure of 5X10-7 Torr and an instantaneous deposition rate in excess of 8500 angstroms/minute, near-bulk resistivity for aluminum alloy films can be achieved.

- Film Hardness

By keeping oxygen content below, film hardness for typical 1 micron thick aluminum silicon films can be kept below 100 kg/mm2 after annealing at 500oC, minimizing bonding failures.

- Specularity

High quality aluminum alloy films of 70-90% relative reflectance are routinely produced in high rate DC Delta magnetron systems, yielding wafers easily accommodated in today’s projection mask aligners.

Optional load lock pumping and wafer degassing further minimize water vapor and hydrogen, the principal contaminants that contribute to hillock growth and poor specularity. As metallization films become thicker and specularity degrades, further reduction of unwanted gases can be achieved through the use of supplemental hydrogen getter pumping in the Model 4410 and other Delta cathode systems.

- Step Coverage

The high rate sputtering made possible with Perkin Elmer Delta DC magnetron cathodes produces sufficient heat to maintain film temperature in the ideal range. Heating the substrate in this manner and re-sputtering the deposited material through RF bias improves coverage of vertical surfaces in VLSI structures. It also minimizes cracks and cusping.

- Optional High Performance Delta Cathodes

Provide more uniform deposition over a wider annular region of the pallet. A maximum of twenty two 100mm wafers can be loaded yielding 50% more throughput for a typical metallization process. The HIGH THROUGHPUT option consists of a modified shaping aperture, a high performance Delta cathode and a pallet nested for twenty two 100mm wafers. The region of high uniformity is extended across the total 8″ annular width of the pallet. A uniformity of +/-7% is achieved across a 73/4 inch band suitable for mounting two concentric rows of 100mm wafers. This wide brand of uniformity means that 51/4“, 8″, or 14” recording discs can be accommodated in the system.

- The Delta Cathode Dual Deposit Sputter Module

The Delta Cathode Dual Deposition Sputter Module, operable in either a dual DC mode or DC and RF mode, is designed for higher throughput and larger scale production. Separate power suppliers allow independent application of either DC or RF energy to two delta cathodes simultaneously. The dual deposit sputter module for Models 4410, 4450 and 4480 is the choice for co-sputtering of refractory metal silicides for VLSI circuits. The dual deposit sputter modules and the co-sputtering technique allow the deposition of contamination-free films.

Features:

- High rate Delta DC magnetron

- High throughput operation

- Fully process characterized for aluminum alloys

- High uniformity

- DC, RF, Etch, and Bias operation

- Ultra clean vacuum system

- Load lock operation

- UHV design

- Flexible for development or production use

- Any size substrates up to 8″ diameter

- Various pumping and power options

- Optional system and process controllers

- Cassette to cassette operation(Model 4480)

- Co-sputter option for silicides

- Operation gas controller

| PERFORMANCE FOR TYPICAL METALLIZATION PROCESS-100mm WAFERS | ||

| Standard Delta System | High Throughput Delta Systems | |

| Pallet capacity | 14 | 22 |

| Uniformity | +/-7%(63/4“) band | +/-5%(73/4” band) |

| +/-7%(8″ band) | ||

| Typical Target Life | 3220 wafers | 4070 wafers |

| Typical Deposition Rate | 200 Angstroms/kw-min | 170 Angstroms/kw-min |

| Typical Deposition time | 5 minutes | 5.9 minutes |

| *Runs per hour | 4.0 | 3.8 |

| Throughput | 56 wafers/hour | 83 wafers/hour |

| * Assumes 10 minute pumping, wafer exchange and venting cycle, some processes require pre-heating, extending the loading cycle by as much as 5 minutes. | ||

| Delta Cathode Systems Performance Specifications(Typical) | |||

| Material | Al/1%Si | Al/1%Si/2%Cu | Al/4%Cu |

| DC Power | 10 kw | 10 kw | 10 kw |

| RF Bias | -25V | -25V | -25V |

| Base Pressure | 5X10-7 Torr | 5X10-7 Torr | 5X10-7 Torr |

| Pumpdown Time | 3.5 min. | 3.5 min. | 3.5 min |

| Argon Pressure | 8X10-3 Torr | 8X10-3 Torr | 8X10-3 Torr |

| Table Rotation | 2-5 rpm | 2-5 rpm | 2-5 rpm |

| Deposition Rate | 2000 Å /min | 2000 Å /min | 2000 Å /min |

| Film Temp(max) | 375oC | 375oC | 375oC |

| Film Thickness | 1.0 microns | 1.0 microns | 1.0 microns |

| Step Hight | 1.0 microns | 1.0 microns | 1.0 microns |

| Step Slop/Coverage | 70o/70% | 70o/70% | 70o/70% |

| 80o/60% | 80o/60% | 80o/60% | |

| 90o/50% | 90o/50% | 90o/50% | |

| Specularity | 70-75% | 80-85% | 90-95% |

| Resistivity | 2.85-2.90μΩ-cm | 2.95-3.00μΩ-cm | 2.95-3.00μΩ-cm |

| Grain Size | 1-2μm | 0.3-0.5μm | 0.3-0.5μ |

| Film Hardness | |||

(Annealed)85kg/mm2100kg/mm2120kg/mm2CV Shift0.25V0.15V0.15V*Uniformity+/-7%+/-7%+/-7%* Typical results with Standard Delta Cathodes. Higher uniformity and throughput can be achieved with high performance Delta Cathodes and high throughput option. Throughput is process dependent and may vary depending on etch and pre-heat cycles.

Series 2400

Highest Quality Sputtering-

Superior Performance-

Wide Selection of options-

In a laboratory or low-volume production environment, where the high throughput levels of the 4400 Series are not required, the 2400 Series is the ideal alternative for high quality sputtering in a wide variety of applications.

Model 2400-8SA

The Perkin-Elmer Model 2400-8SA features a large 211/2” rotating, water cooled annular table with a capacity of sixty-four 2″, thirty 3″, or thirteen 4″ wafers.

Used in conjunction with a cathode shaping aperture, the rotating table permits high uniformity. A 4″ wafer vertical range of the table facilitates coating bulk substrates. As an added feature, up to three 8″ round cathodes may be specified allowing sequential deposition from several targets or alternately, static deposition or heating from any target position.

Power Splitting is an optional feature of the 2400-8SA system. With this feature, RF power can be applied to two cathodes simultaneously in any desired ratio from 5 to 95%. Combined with the continuous substrate rotation feature, an infinite number of alloy compositions can be developed simply by varying the power division between target.

Model 2400-8L

The Model 2400-8L load lock system ensures a constant inert gas or vacuum environment allowing rapid pumpdown to base pressure and elimination of target pre-cleaning. High partial pressure of water vapor is no longer a problem, even in areas of high humidity. Additional water vapor pumping is possible with an optional Meissner Trap. By eliminating the need to break vacuum in the process chamber, the 2400-8L load lock reduces both pumpdown time and contamination of targets and internal chamber surfaces. Load lock pumping is provided by a mechanical pump which is shared with the process chamber vacuum system. Load lock pumpdown and pallet transfer are automatically controlled. Sequence and valve position are displayed on front control panels.

A water-cooled 8″ diameter substrate table rotates the pallet 360o and automatically aligns it precisely under any one of the three targets or the etch position. Substrates can be loaded, processed, and unloaded in minutes improving run to run yields. A full pallet of wafers can be transferred from air to a properly maintained process chamber and pumped down to a base pressure of 5X10-7 Torr in less than five minutes.

Series 2400-Capabilities, Features, Options

- High Uniformity

Careful cathode and chamber designs mean high uniformity,. Integral copper channels in the anode tables insure even distribution of cooling water and RF power.

- High Throughput

The 2400-8SA features a 211/2” table which enables processing of large wafer batches. The 2400-8L utilizes a smaller pallet but provides a unique load lock system to dramatically reduce pump-down time. Either approach maximizes efficiency.

- Maximum Process Control

Both 2400 Series systems offer a wide choice of target materials, machine operating models, and gas controls with capability to perform a variety of thin film tasks.

- RF Bias

The Perkin-Elmer 2400 Series RF Bias capability enables high quality films with a variety of materials. The RF bias provides improved step coverage, controllable intrinsic stress for metal or dielectric films, improved alloying materials and stoichiometry, resistivity that approaches bulk values, precisely controlled film densities and impurities and reduced argon content.

- Uniform Deposition

The 2400-8SA and 2400-8L use uniformity shaping apertures to compensate for the geometry of the cathode sputtering pattern. The rotating substrate table further improves uniformity in the 2400-8SA. The 2400-8L utilizes a double-disk dark space shield to eliminate edge sputtering from the cathode plate and provide exceptional plasma confinement.

- Operation Mode Selection

In all 2400 systems, the mode selector switch provides a choice of modes:sputter deposit, bias sputter and sputter etch.

- Standard RF Features

Servo-Match automatic turning maintains proper turning despite variations in target emission, pressure or RF power. A power stabilizer holds RF power constant.

FEATURES

The 2400-8SA Rotating Table Multi-Target System

- Sequential deposition from DC magnetron, RF magnetron and conventional RF cathodes

- Simultaneously sputtering from 2 targets

- High deposition rates for metals and dielectrics

- Low substrate temperature in both RF and DC magnetron deposition modes

- Single pass or multi-pass capability

- Servo-Match automatic turning

- High loading capacity

- Three target capability

The 2400-8L Load Lock Multi-Target System

- Load lock for reduced pump-down time

- Remotely adjustable anode/cathode spacing

- No cross-contamination

- Pallet heated on substrate table with rapid cool-down

- Servo-Match automatic turning

- Fast turnaround through automated operation.

- Three target capability

Series 4400/2400-Options

| Options | 4400 | 4410 | 4450 | 4480 | 2400-8L | 2400-8SA |

| Process Chamber Heater, 350oC | X | X | X | X | X | X |

| RF/RF Power Split, Co-Sputter | X | X | ||||

| Dual DC;RF/DC. Co-Sputter | X | X | X | |||

| Process Chamber Turbo Pump | X | X | X | X | X | X |

| Process Chamber Diffusion Pump | X | X | ||||

| CTI-8 Cryopump | X | X | X | X | X | X |

| Hydrogen Getter Pump | X | X | X | X | ||

| Load Lock Heat, 200oC | X | X | Std | Std | ||

| Load Lock Turbo Pump | X | X | Std | Std | ||

| 5kw DC Power Supply | X | X | X | X | X | X |

| 10kw DC Power Supply | X | X | X | |||

| 1kw RF Generator | X | X | X | X | X | X |

| 2kw RF Generator | X | X | X | X | X | X |

| 3kw RF Generator | X | X | X | |||

| RF Power Stabilizer | X | X | X | X | X | X |

| RF Power/Voltage Stabilizer | X | X | X | X | X | X |

| Gas Controller | X | X | X | X | X | X |

| Digital Clock Timers | X | X | X | X | X | X |

| Process Sequence | X | X | X | |||

| High Throughput Option | X | X | * | |||

| DC Sputter/RF Bias Option | X | X | X | X | ||

| * Useable in Manual Load Mode only | ||||||

Model 4410

DeltaTM Cathode Production Sputtering System

Perkin-Elmer Ultek Division

MODEL 4410 SPECIFICATIONS

Typical Process Results

High quality metal films can be routinely achieved:

Material:Al-1%Si

Power:9kw

Table rotation:10 rpm

Argon pressure:8 mTorr

Film thickness:1.04 microns

Deposition time:5.8 minutes

Step height: 1.10 microns

Step slope: 80o

Step coverage: 62% horizontal-to-vertical

Specularity: 65-75%

Resistivity: 2.85μΩ-cm

Grain size:2 microns

Process Chamber

- 28″ diameter X 12″ high stainless steel cylinder with 6″ CF flange viewport and load lock port

- 28″ diameter stainless steel top plate with 3 delta cathode ports

- 28″ diameter stainless steel base plate

- 11/2” air-operated roughing isolation valve

- Solenoid-operated gas inlet valve

- 3/8” solenoid-operated vent valve

- 11/2” blanked-off leak check port

- Removable deposition shields

- 23″ diameter, 3-position water-cooled annular substrate table with adjustable 1-10 rpm SCR motorized table drive

- Full circle shutter with vane shutter

- Chain drive pallet carrier transport

- Automatic plasma igniter

- Heavy duty electric hoist

Load Lock

- 30″ x 28″ x 8″ stainless steel load lock chamber with aluminum cover

- 2″ air-operated roughing isolation valve

- 3/8” solenoid-operated vent valve

- 23″ diameter molybdenum annular substrate pallet

- Pallet carrier and chain drive transport

Vacuum System

Roughing

- 7 cfm mechanical pump for process chamber and load lock roughing

- 2″ diameter roughing lines with electropneumatic valve

- Surface-area Versa-trapTM in roughing line

High vacuum pumping

- 2 stage cryopump with 1000 l/s pumping speed for air, including chevron, water-cooled compressor and lines, automatic regeneration controller and plumbing kit.

- 71/2” O.D. (6″ ASA) aluminum air-operated gate valve

- Air-operated venetian blind throttling valve

Residual gas pumping

- Full flood Meissner trap with 30,000 l/s pumping speed for water vapor

- Insylated LN2 lines

- LN2 sensor, solenoid and relief valve

Control

- Vacuum gauging package including basic digital vacuum gauge control (DGC II), ionization tube and two thermister tubes

- Automatic pump-down controller

- Automatic lock controller

Options

- Diffusion-pump system including 1500 l/s oil diffusion pump, LN2 chevron baffle, water-cooled baffle and water-flow switch.

- Turbomolecular-pumped system including 450 l/s turbo pump, foreline manifold with 11/2” air-operated isolation valve, and water-flow switch(less throttling valve)

- Polycold-compatible quick-purge Meissner trap.

Sputtering Control Module

- 3 kw water-cooled RF matching network

- RF power on/off switch

- RF power level control

- 4 position rotary sputter mode selector

- 3 position rotary target selector

- 2 position shutter position switch

- Manual load and tune controls

- 15-turn vernier 0-10% bias control

- Forward and reflected RF power meters

- Substrate bias meter

- Target bias meter

- Target-to-table spacing meter

- Servo-MatchTM automatic turning (mounted in lower console)

Cathode Options

- Delta DC magnetron cathode assembly with water-cooled backing plate and anode

- Delta-to-8-inch round cathode adaptor

- 8″ diameter RF magnetron cathode assembly

- 8″ diameter RF diode assembly

- 8″ diameter DC magnetron cathode assembly

- Delta blank-off plate

- MagnabondTM 8-inch round target kit for DC cathodes

- Bolt-on Delta target kit

Power Options

- 2 kw RF Generator

- 3 kw RF Generator

- 5 kw programmable DC magnetron power supply including digital clock timer

- 10 kw programmable DC magnetron power supply including digital clock timer

Utilities

- Rear-mounted electrical, water, gas and LN2 inlet panel

- Power distribution box

- Water-flow switch panel and manifold

System Options

- Precision 3 rpm to 5 rpm servo-driven table drive

- Water-cooled process chamber

- Water-cooled top plate

- Dura gas inlet system

- Wide range digital vacuum gauge control

- Continuous viewing vacuum port

Accessories

- Load lock pumping and heating system including 100 l/s turbomolecular pump, 17.7 cfm mechanical pump, 200oC heater and controller

- Microprocessor for machine and process control

- Programmable RF power stabilizer

- DC sputter with RF bias

- Process chamber 350oC heater (mounted in cathode position)

- Digital clock timers

- Annular pallet nested for 64 2-inch,30 3-inch or 13 4-inch wafers

- Polycold refrigeration system for Meissner trap

- Delta target copper backing plate

- Pressure or flow controllers

Microprocessor Operation Option

Ultek’s microprocessor controller option permits automated control of machine functions and process parameters including load lock operation, pump-down venting and all process sequences. Up to five 16-step process sequences can be stored in the system’s memory to facilitate process change.

An interactive CRT facilitates programming. Unconditional looping is available for repetitive processes. Other capabilities include: program listing, hard copy records and interface with other computer systems.

THE DELTA CATHODE SYSTEM:MODEL 4410

Perkin-Elmer’s Model 4410 delta cathode production sputtering system is designed for high yield in production environments demanding maximum throughput for metal deposition. It also provide a high level of flexibility in process control for other materials.

The 4410 uses a delta-shaped cathode that eliminate the need for a large-area uniformity-shaping aperture. This dramatically increases throughput while maintaining high wafer-to-wafer uniformity.

Contrasted with circular cathodes, target utilization is substantially higher. Up to 35% of the target can be sputtered before target change, and some 60% of the sputtered material actually reaches the substrate pallet. This results in a lower cost per wafer and less frequent target changes. Up to three delta or 8-inch round targets may be installed for sequential deposition of three different materials without breaking vacuum.

The 4410 employs a fast cycle load lock, two-stage cryopump and full flood Meissner trap to maintain the process chamber at high vacuum and in a clean condition at all times. The process chamber is fabricated of stainless steel for contamination-free performance. A base pressure better than 5 X 10-7 Torr is achieved within 3.5 minutes from loading substrates into the load lock. Typical cycle time, with optional load lock heating and pumping, is 12 to 15 minutes for the deposition of 1 micron of aluminum.

System Highlights

- High rate delta DC magnetron sputtering: Aluminum and aluminum alloys can be sputter deposited at rates in excess of 1800 Å /min, with loads of thirty 3-inch or thirteen 4-inch wafers.

- High throughput operation: Automated load lock and controller sequences provide for efficient pump-down and pallet transfer to process chamber, maximizing throughput.

- High uniformity: +/-7% deposition uniformity guaranteed with water-cooled rotating annular substrate table;+/-5% achievable.

- The right sputter mode for each application: Sputter deposit, 0-10% RF bias sputter. DC bias sputter, sputter etch to 2 kw, RF magnetron, RF diode, DC delta magnetron.

- Ultra-clean vacuum: Cryopump and Meissner-trapped process chamber ensures contamination-free conditions especially important for critical processes such as the deposition of aluminum and platinum.

- Designed for operator safety: Two-button operation initiates pump-down and load sequence. Safety interlocks on DC and RF suppliers.

- Easy maintenance: Removable deposition shields permits easy system cleaning. Automatic cryopump regeneration minimized downtime and inconvenience.

- Key function clearly displayed: Valve position and system status are continuously displayed by quick-reading LEDs on front panels.

- Easy wafer loading: Tweezer grooves facilitate wafer loading. Nested pallets are optional.

- A fail-safe system: Water flow switches on cathodes, matching network and vacuum system automatically shut the system down in case of cooling system failure.

The Sputtering Process

Sputtering is a momentum transfer process in which atoms from a cathode/target are driven off (or sputtering) by bombarding ions. In this process the momentum of the bombarding particles is more important than the energy. For example , a hydrogen or helium ion accelerated to 3,000 eV will cause very little sputtering compared to an ion of argon (which is chemically inert) with the same 3,000 eV energy, simply because the much higher hydrogen or helium ion has much less momentum.

Sputtered atoms travel until they strike a substrate , where they are deposited to form the desired thin film. As individual atoms, they can be chemically active and form compounds with the ions and atoms of the bombarding gas. For this reason, inert argon typically is used as the bombarding gas. In some applications, however, a reactive gas is intentionally added to the argon to alter the chemical composition of the deposited film (e.g., nitrogen gas in combination with tantalum sputtering to form tantalum nitride, TaN).

When argon atoms strike the target, their electrical charge is neutralized and they return to the process as atoms. If the target is an insulator, the neutralization process results in a positive charge on the target surface. The charge may grow so large that the bombarding ions are repelled and the sputtering process stopped. To allow the process to continue, polarity of the target must be reversed, attracting enough electrons from the discharge to eliminate the surface charge. This periodic reversal of polarity is accomplished automatically by applying RF voltage to the target assembly ( hence the term “RF” sputtering).

Of interest here is the diode rectifier-like behavior of the target and discharge systems. This results from the vast difference in mobility of ions and electrons. Electrons , being so much fast, are attracted in greater numbers to the target during the positive half-period of the RF voltage than are ions during the negative half-period. Thus, the target develops a negative DC bias.

4400-Series Production Sputtering Systems perform a number of sputtering process, each of which is ideal for a different application.

RF Diode Sputter Deposition

When the vacuum set point is reached, sputtering gas (typically argon) is introduced in the process chamber at a pre-selected rate (typically 40 sccm). A plasma, or self-sustaining glow charge , initiated by an automatic plasma igniter, appears when RF power is applied between the target and electrical ground, ionizing the argon gas.

A negative (-) potential applied to the target, as a result of the applied RF power, attracts the ionized argon at a momentum determined by a) the magnitude of applied potential and b) the mass of the ion. The momentum of the incoming ion is transferred to the target material, causing surface atoms or molecules of target material to be ejected (sputtered). These sputtered atoms travel across the gap separating the target (cathode) and substrate table (anode), and are deposited on the substrate (wafers) which are arranged on the substrate pallet.

RF Magnetron Sputter Deposition

RF magnetron and RF diode sputtering are very similar, except that during RF magnetron sputtering a magnetic field deflects the secondary electrons (which are produced during normal sputtering operation) away from the substrates. The sputtering process, which is cooler than RF diode sputtering, permits materials to be sputter deposited on substrate at lower temperatures and greatly reduces the chance of radiation damage to delicate substrates.

Because the impedence of a magnetron is lower, higher power densities are possible at lower potentials, effecting high sputter rates.

DC Magnetron Sputter Deposition

DC magnetron targets enhance the plasma density and increase the sputtering rate, by trapping electrons in an electromagnetic “envelope”. This “envelope” is formed when lines of the magnetic field enter and exit the target face and when the loci of maximum transverse magnetic fields form a closed figure. Because the currents involved are very large, a separate, positively-biased anode (a dark space shield) is used to collect the electrons. A similar dark space shield is used in RF diode and RF magnetron deposition, This dark space shield prevents the sides of the target and target backing plate from sputtering.

RF Sputtering-Etching

Essentially the reverse process of RF diode sputter deposition, in which the substrate table becomes the cathode (negative pole) and the target assembly becomes the anode (positive pole). Under these circumstances, surface material from the substrates is ejected. Surface impurities are ejected along with substrates material, making this process useful for pre-cleaning substrate prior to sputter deposition. In order to prevent ejected material from contaminating the target, s shutter is positioned between target and substrate.

Bias Sputter Deposition

Bias sputtering combines the DC or RF sputtering and the RF etching operations. While DC or RF power is applied to the target, a small amount of RF is also applied to the substrate table. As a result, the substrate and target are both bombarded by ions ( the substrate to a lesser extent than the target ). In many applications this process yields superior quality films than can be attained using DC or RF sputtering with grounded substrates. Bias sputtering influences the crystal structure, and tends to re-sputter trapped argon from the growing film during deposition and rearrange individual atoms of the sputtered material; this improves stoichiometry and step coverage. Bias sputtering can be used to adjust film resistivity and film stress to desired levels.

Reactive Sputtering

Some metals, such as nitrides and oxides, are best deposited by this method: the target is the parent metal and a small amount of nitrogen or oxygen is introduced into the process chamber along with the argon sputtering gas. Because ionized gases are typically highly reactive, a film deposited in a mixture of argon and a reactive gas will often form a compound with the reactive gas (e.g., a nitride or an oxide).

Co-Deposition

Sometimes called co-sputtering or dual deposition, co-deposition is identical in principle and practice to other types of sputter deposition, except that two targets (typically of different materials) are simultaneously activated. Substrates passing sequentially and repeatedly beneath the targets are coated with alternating, very thin films of two materials. Under certain circumstances, the resultant film can be equivalent to or better than one formed using a composite target. During co-deposition, both targets may be RF, both DC, or one RF and one DC.

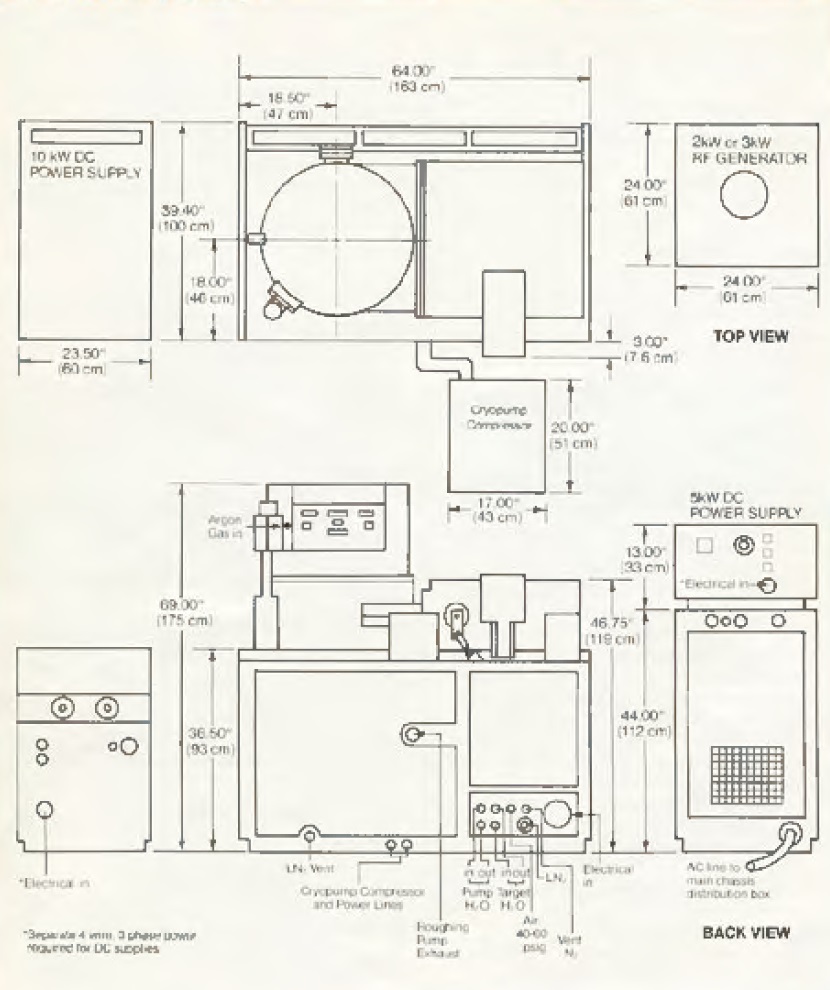

Perkin-Elmer 4400 Sputtering Deposition Equipment Dimension

Pls contact us via email sales@semistarcorp.com if you are interested in the following. These are subject to prior sale. These are only for end user. Appreciate your time.

| 1 | 000-0000// AMAT E5500 HOIST ENDURA 5500 SPUTTER TNAN [ASIS] |

| 2 | 0020-09031, AMAT, INSULATING WASHER – ONLY. Part from P5000 SPUTTER & TR |

| 3 | 0020-09911 / AMP-266-009, CARRIER, SPUTTER / APPLIED MATERIALS AMAT |

| 4 | 0020-09911, AMAT, Applied Materials CARRIER, SPUTTER, From P5000 Sputter kit |

| 5 | 0020-09912 PIN LIFTING SPUTTER, lot of 7 |

| 6 | 0020-09933 / GAS DISTR. PLATE SPUTTER / APPLIED MATERIALS AMAT |

| 7 | 0020-10527, AMAT, Applied Materials, SPUTTER PIPE , Teflon |

| 8 | 0021-11382 / MAGNET ASSEMBLY, ENDURA PVD SPUTTERING / APPLIED MATERIALS AMAT |

| 9 | 00-680909-00 / RAM BELLOWS ASSY,PRESSURE PLATE, ,SPUTTER,00-680909-00 / NOVELLUS |

| 10 | 0200-09086, AMAT, Applied Materials, QUARTZ RING 200MM SPUTTER ETCH |

| 11 | 0200-09090; RING QUARTZ 200MM SPUTTER ETCH BGR, Applied Materials (AMAT) |

| 12 | 0200-09608, AMAT, Applied Materials,SHLD QUARTZ,200MM,SPUTTER ETCH |

| 13 | 04-716797 /MULTI RANGE DC SPUTTERING POWER SUPPLY M2000,M2I / VARIAN VPW2870P5-S |

| 14 | 1,000 pounds of pure silicon sputtering targets polysilicon poly-silicon |

| 15 | 1021-12-151 / WEST COAST QUARTZ RING, 8″ SPUTTER CERAMIC / WEST COAST QUARTZ |

| 16 | 10538 ANATECH SPUTTERING SYSTEM HUMMER 10.2 |

| 17 | 115-0101// HITACHI 03E-0601, E-120 ION SPUTTER |

| 18 | 116-0503// AMAT APPLIED 0200-09087 QTZ RING 150MM SPUTTER |

| 19 | 119-0301// HONEYWELL E5500 11″ DB ENDURA 6″ SPUTTERING TARGET |

| 20 | 21″x 6″ Cadmium Tin Alloy Rotary Sputtering Target 99.9% (Cd)66.5(Sn)33.5 Wt% |

| 21 | 304-200225 Rev A, Sputtering |

| 22 | 324-0202// AMAT APPLIED 0020-39554 HARD STOP, WAFER LIFT, SPUTTER |

| 23 | 342-0101// AMAT APPLIED 0020-09912 LIFTING PIN, SPUTTER |

| 24 | 342-0101// AMAT APPLIED 0020-09912 LIFTING PIN, SPUTTER |

| 25 | 35mm Slide-#467-1961-Sputterer Spring |

| 26 | 3648 Sputtering Materials Inc. 03069440002-A Boundment Backing Plate RND: 4″ |

| 27 | 3744281 – Leybold Heraeus – CONTACT ELEMENT – FOR SPUTTERING 011/110 |

| 28 | 4″ Glass For Viewport UHV Sputtering |

| 29 | 6 inch diameter round sputter gun |

| 30 | 771 gram 27Oz 99.95% Niobium Columbium metal sputtering target element 41 sample |

| 31 | 786 gram 28Oz 99.95% Niobium Columbium metal sputtering target element 41 sample |

| 32 | 8 inch Reflective “Splatter&Adhesive” sputtering Reactive Shooting paper |

| 33 | 9.5″ Spit & Sputter Dying Perch Muskie Topwater Lure Handcrafted 6.5 Oz |

| 34 | 99.99% Aluminum 8.7/8″x 3.3/8″x 0.310″ Sputter Target Approx.103 Grams |

| 35 | 99.995% Titanium Sputtering Target Plate Diameter 57mm 2.24” Thick 5mm |

| 36 | 99.995% Titanium Ti Sputtering Target Disc Plate Diameter 150mm Thick 5mm |

| 37 | 99.995% Titanium Ti Sputtering Target Disc Plate Diameter 85mm Thick 5mm |

| 38 | 99.995% Titanium Ti Sputtering Target Plate Diameter 2” Thick 10mm |

| 39 | 99.995% Titanium Ti Sputtering Target Plate Diameter 70mm Thick 5mm |

| 40 | 99.995% Titanium Ti Sputtering Target Plate Diameter 75mm Thick 3mm |

| 41 | A&N Chain Clamp Sanitary Pipe Ultra Low Vacuum Sputtering Deposition Chamber |

| 42 | Advanced Energy 10kW Magnetron Drive Power Supply Sputtering MDX 2226-000-F |

| 43 | ADVANCED ENERGY 3152283-000A CONTROLS BOARD FOR MDX TYPE DC SPUTTER POWER SUPPLY |

| 44 | Advanced Energy 3157600-003 PEII Reactive Sputtering PSU 1100V 10kW 40KHz 208VAC |

| 45 | Advanced Energy 3157600-004 PEII Reactive Sputtering PSU 10kW 208VAC |

| 46 | Advanced Energy 3157600-004 PEII Reactive Sputtering PSU 1100V 10kW 40KHz 208VAC |

| 47 | Advanced Energy AE Ascent 40KW DC Sputtering Power Supply |

| 48 | ADVANCED ENERGY AE MAGNETRON CATHODE SPUTTERING T HEAD 6″ WAFER 3151701-010 |

| 49 | advanced energy AE MDX 2.5 2500w dc sputtering power supply single phase amat |

| 50 | Advanced Energy MDX 1K Magnetron Power Supply 1Kw, 115VAC, Single-Phase, 16A |

| 51 | Advanced Energy MDX 1K Magnetron Sputter Power Supply 1Kw, 115VAC, 1-Ph, 16A |

| 52 | Advanced Energy MDX 2.5K 3152224-031A DC Sputter Power Supply 200-208V, 220-240V |

| 53 | Advanced Energy MDX 5K Magnetron Drive 5 kW Sputter Power Supply 2011-000, USA |

| 54 | Advanced Energy MDX 5K Magnetron Drive 5kW Sputter Power Supply 2011-000-E USA |

| 55 | Advanced Energy MDX II 3152256-005F DC Sputter Power Supply 18KW 400V3-phase 32A |

| 56 | Advanced Energy MDX II 3152256-209C DC Sputter Power Supply |

| 57 | Advanced Energy MDX-1K, 2105 Dc Sputter Power Supply |

| 58 | Advanced Energy MDX-2.5K DC Sputtering Power Supply 2224-006-B Output 500-1800V |

| 59 | Advanced Energy MDX-500 DC Sputtering Power Supply – 6 month wrty. |

| 60 | Advanced Energy Pinnacle 3152352-123B Pulsed DC Sputter Power Supply, 8 KW |

| 61 | Advanced Strategies In Thin Film Engineering By Magnetron Sputtering |

| 62 | Advanced Strategies in Thin Film Engineering by Magnetron Sputtering by Alberto |

| 63 | ADVANCED STRATEGIES IN THIN FILM ENGINEERING BY MAGNETRON SPUTTERING GU MDPI AG |

| 64 | AE ADVANCED ENERGY MDX 1.5K MAGNETRON SPUTTERING DC POWER SUPPLY. 500V 3A |

| 65 | AE Advanced Energy MDX 1.5K Sputtering DC Power Supply |

| 66 | AE Pulsed Plasma PEP-2500 bipolar dc rf sputter power |

| 67 | AJA INTERNATIONAL ST20 RF/DC sputtering source for 2″ x 0.25″ target |

| 68 | AJA INTERNATIONAL ST30-MM , RF/DC HV Sputter Source 3 Inch |

| 69 | AJA Intl Sputtering Target – Iron – 2″ Dia – 1/8″ Thick – 99.95% Pure |

| 70 | Al-Sc 87.5/12.5 wt% Alloy Sputtering Target |

| 71 | Aluminum Al Sputtering Targets – 2.00″ Diameter, 0.250″ Thick – Kurt J. Lesker |

| 72 | Aluminum MRC Chi Inset Sputter Target: Al 99.9+ With Materials certification |

| 73 | Aluminum nitride, AlN – Sputtering Target |

| 74 | Aluminum SEM Sputtering target: Al 99.999% pure, 54mm diameter x 1mm thick |

| 75 | Aluminum SEM Sputtering target: Al 99.999% pure, 57mm diameter x 1mm thick |

| 76 | Aluminum sputter target, Al 99.999% pure 2″ diameter x 0.125″ thick |

| 77 | Aluminum sputter target, Al 99.999% pure 2″ diameter x 0.25″ thick |

| 78 | Aluminum sputter target, Al 99.999% pure 50mm diameter x 3mm thick |

| 79 | Aluminum Sputtering target: Al 99.999% pure, 63mm diameter x 1mm thick |

| 80 | Aluminum Target for Nobler NT 1500 sputter coater |

| 81 | Aluminum, Al – Sputtering Target |

| 82 | Aluminum/Indium sputter target Al/In 1:1 at%, 99.99% pure 3″ dia x 1/4″ thk |

| 83 | Aluminum/Manganese sputter target Al/Mn 99.8/0.2 wt% 3″ diam x 0.25″ thk |

| 84 | Aluminum/Nickel sputter target 50/50 Al/Ni at% 99.99% rod 4.2″ long x 0.5″ diam |

| 85 | Aluminum/Silicon MRC Chi Sputter target: Al/Si 99/1 wt% |

| 86 | Aluminum-doped Zinc Oxide Sputtering Target AZO |

| 87 | AMAT 0010-01994 Rev.001, Magnet Assembly, PVD, Endura, Sputter Chamber |

| 88 | AMAT 0010-09425, Grounding Strap, Assy, Sputter Etch |

| 89 | AMAT 0010-20818 ENDORA 5500, MAGNET, SPUTTER, PVD source |

| 90 | AMAT 0020-00663, Insulator, Source, 11 inch, Ceramic, PVD, Sputter |

| 91 | AMAT 0020-07701 Shield Upper Ti TiN Al Flame Spray Endura sputter Chamber |

| 92 | AMAT 0020-09911 MXP Sputter, Etch Carrier, Wafer lift with 4 Pin |

| 93 | AMAT 0020-09911 SPUTTER CARRIER with 0020-09912 |

| 94 | AMAT 0020-10050 Pedestal, Flat Sputter |

| 95 | AMAT 0020-10050 Pedestal, Flat Sputter |

| 96 | AMAT 0020-10051 Ring, Top Sputter |

| 97 | AMAT 0020-10051, Ring, Top Sputter |

| 98 | AMAT 0020-10527 sputtering pipe, etch chamber, teflon insulator, MXP |

| 99 | AMAT 0020-21467 Adapter Source, PVD Chamber, Sputter, Endura Tool |

| 100 | AMAT 0020-21707 8 Inch wafer hoop, Lifter Endure, PVD sputter |

| 101 | AMAT 0020-21707 8 Inch wafer hoop, Lifter Endure, PVD sputter, CDSL-D-280 |

| 102 | AMAT 0020-21707 8 Inch wafer hoop, Lifter Endure, PVD sputter, CDSL-D-299 |

| 103 | AMAT 0020-24640, 6JMF, Tin clampring, PVD Sputter chamber |

| 104 | AMAT 0020-29719 Pre clean Endura sputter Pedestal quartz chuck |

| 105 | AMAT 0020-29719-PA, Endura, PVD, Chuck, Pedestal, Sputter Chamber |

| 106 | AMAT 0020-29719-PA, Endura, PVD, Chuck, Pedestal, Sputter Chamber |

| 107 | AMAT 0020-62669 SHIELD, APERATURE, B/S SPUTTER |

| 108 | AMAT 0021-11075-001, Endura, PVD, Chuck, Pedestal, Sputter Chamber |

| 109 | AMAT 0021-11382 Magnet Assembly, Endura PVD sputtering |

| 110 | AMAT 0021-76516 Chamber Liner, PVD Sputter, Endura Tool |

| 111 | AMAT 0040-01761 Endura Pre-clean Chamber Body, Sputter, PVD |

| 112 | AMAT 0040-20561 Belljar, Preclean II, Endura, Sputtering Plate |

| 113 | AMAT 0040-20561 Belljar, Preclean II, Endura, Sputtering Plate |

| 114 | AMAT 0040-20561 Belljar, Preclean II, Endura, Sputtering Plate |

| 115 | AMAT 0200-09084 Shield, 125mm, Sputter Etch |

| 116 | AMAT 0200-09088-B Quartz Ring 125MM Sputter Etch |

| 117 | AMAT 0200-09091 Graphite Ring For P5000 Sputter Etch (FCVD02C) |

| 118 | AMAT 0200-09608, Shield Quartz 200mm, Sputter |

| 119 | AMAT 0200-09608-C, Shield Quartz 200mm, Sputter |

| 120 | AMAT 0200-20059 PVD Sputter Liner Clamp, 6″, Aluminum, SMF, STR |

| 121 | AMAT 0200-20061 Insulator, Quartz, 6″, PVD Sputter chamber PCII |

| 122 | AMAT 233-2889-25 AMAT PVD endura clamp ring Sputter chamber |

| 123 | AMAT 6″ ENDURA HEATER ASSEMBLY, PVD SPUTTER CHAMBER |

| 124 | AMAT Applied Materials 0020-09933 Gas Distribution Sputter Plate |

| 125 | AMAT Applied Materials 0020-09933 Gas Distribution Sputter Plate |

| 126 | AMAT APPLIED MATERIALS 0100-20255 RF Sputtering |

| 127 | AMAT Applied Materials 0140-16349 Harness Assembly Sputter Chamber Right |

| 128 | AMAT Applied Materials 0140-16350 Harness Assembly Sputter Chamber Rear |

| 129 | AMAT Applied Materials 0140-16351 Harness Assembly Sputter Chamber Bottom |

| 130 | AMAT Applied Materials 0200-09088-B Quartz Ring 125MM Sputter Etch |

| 131 | AMAT Applied Materials 0200-09088-C Quartz Ring 125MM Sputter Etch |

| 132 | AMAT Applied Materials 0225-34794 Gas Distribution Sputter Plate |

| 133 | AMAT APPLIED MATERIALS QTZ RING, 200mm SPUTTER ETCH, AMAT P/N 0200-09086 |

| 134 | AMAT Endura Sputter Chamber Source Magnet Holder, Lock |

| 135 | AMAT Magnet Assembly, PVD, Sputter, 329947 |

| 136 | AMAT PVD Chamber Lift Assembly, Endura Sputter Chamber, SMC NCDQ2WB63-01-0193US |

| 137 | AMAT PVD Endura sputtering chamber clamp ring |

| 138 | Anatec Limited HUMMER VI Sputtering System |

| 139 | Anatech Gold Sputtering Coating Machine with Vacuum Pump Hummer VII |

| 140 | Anatech Hummer 6.2 Sputtering System |

| 141 | ANATECH HUMMER VI-A SPUTTERING SYSTEM |

| 142 | Anatech HUMMER X Sputter System |

| 143 | Anatech HUMMER X Sputter System |

| 144 | ANATECH HUMMER X SPUTTER SYSTEM |

| 145 | Anelva 32 Point PCB Relay Board For 1015/1013 Sputtering System ILC 1013 |

| 146 | ANELVA 9005-41429 SPUTTER TARGET, PVD, COML, BONDING D164 T4, 5N AI-PURE |

| 147 | ANELVA 9005-41429 SPUTTER TARGET, PVD, COML, BONDING D164 T4, 5N AI-PURE |

| 148 | Anelva Sputtering system ICL-1015 Semiconductor Processing Assembly |

| 149 | Angstrom Sciences 99.999% Copper 8.0″ x 0.25″ Sputtering Target |

| 150 | ANGSTROM SCIENCES NICKEL SPUTTERING TARGET (NI) 99.995% BONDED 8”X.250” |

| 151 | Angstrom Sciences Onyx Intevac Sputtering RM PVD Magnet Assembly |

| 152 | Angstrom Sciences PLux Control – Touchscreen – Magnetron Sputtering |

| 153 | Angstrom Sciences RF / DC PLANAR MAGNETRON SPUTTER GUN, 2″ TARGET |

| 154 | Angstrom Sciences Sputtering Cathode with Aluminum Target, 8″ x 3″ |

| 155 | Anode layer ion source plasma sputtering thin film 2.75″ conflat SHV baseplate |

| 156 | Anode layer ion source plasma sputtering thin film deposition |

| 157 | Antimony, Sb – Sputtering Target |

| 158 | Antimony/Telluride sputter target – Sb2Te3 99.99% pure, 1.00″ diam x 4mm thk |

| 159 | Applied Materials (AMAT) 0020-03597 Spider Sputter etch |

| 160 | Applied Materials (AMAT) 0020-09911 CARRIER, SPUTTER |

| 161 | Applied Materials (AMAT) 0020-10527 Sputter pipe |

| 162 | Applied Materials (AMAT) 0020-10527 SPUTTER PIPE |

| 163 | Applied Materials (AMAT) 0020-10527 SPUTTER PIPE TEFLON |

| 164 | Applied Materials (AMAT) 0020-21707 8″ wafer hoop, Lifter Endure, PVD sputter |

| 165 | Applied Materials (AMAT) 0020-30178 SPUTTER ETCH CARRIER SEMICONDUCTOR PART |

| 166 | Applied Materials (AMAT) 0200-09062 WEST COAST QUARTZ RING COVER 150MM SPUTTER |

| 167 | Applied Materials (AMAT) 0200-09083 SHIELD 150MM SPUTTER ETCH |

| 168 | Applied Materials (AMAT) 0200-09088 WEST COAST QUARTZ RING 125MM SPUTTER ETCH |

| 169 | Applied Materials (AMAT) 0200-09089 RING QUARTZ 100MM SPUTTER12NC:790050202513 |

| 170 | Applied Materials (AMAT) 0200-09090 RING GRAPHITE 200MM SPUTTER ETCH |

| 171 | Applied Materials (AMAT) 0200-09608 SHLD QUARTZ,200MM,SPUTTER ETCH |

| 172 | Applied Materials (AMAT) 0220-10629 KIT, SPUTTER ETCH LIFT ASSY MOD |

| 173 | Applied Materials (AMAT) 0225-34794 GAS DISTRIBUTION PLATE, SPUTTER |

| 174 | Applied Materials (AMAT) 0226-97903 CATHODE KIT TUNGSTEN ETCHBACK/ST SPUTTER |

| 175 | Applied Materials 0010-76306 Bearing, Assy. Sputter AMAT Etch |

| 176 | Applied Materials 0020-09911 Carrier,Sputter |

| 177 | APPLIED MATERIALS 0021-61445 300MM RING, DEPOSITION, CU SPUTTER, BCP (Cu) AMAT |

| 178 | Applied Materials AMAT 0200-09063 RING COVERING SPUTTER 4 |

| 179 | Applied Materials AMAT Heater Loop Sputter CPL 102136614 2600W 400V |

| 180 | Applied Materials Heater Loop Sputter, 102136616, 2600W, 400V CPL |

| 181 | Applied Materials Model:0020-10527 Sputter Pipe for FCVD02C |

| 182 | APPLIED MATERIALS PEDESTAL THICK 200MM GRAPH/QUARTZ SPUTTER ETCH 0020-10518 |

| 183 | APPLIED MATERIALS RING GRAPHITE 200MM SPUTTER ETCH, 91-00331A 0200-09090 |

| 184 | Arbogast Hawaiian Sputter Fuss Fish Lure |

| 185 | Arbogast Hawaiian Wiggler #2 1/2 Sputter Fuss 251 F Frog Skirt Box Pamphlet EUC |

| 186 | Assorted Matzuo Lure lot (3) Prism Shad Spit & Sputter, Zen Double Play Crank |

| 187 | Aurion B-MBT-48 Matchbox Prodik 30kW T300 for RF Sputtering Disposition Chamber |

| 188 | Aviza Technology 188850 150mm Back Sputter Shield Trikon |

| 189 | AZO- Sputtering Target |

| 190 | BALL BEARING, SPUTTERING COMPONENTS, P/N: 100195 |

| 191 | Balzers 150mm Wafer Carousel Assembly LLS 801 Sputtering System |

| 192 | Balzers 200mm Wafer Carousel Assembly LLS 801 Sputtering System |

| 193 | BALZERS 5×10″ Sputtering Target 99.999 Pure 95%Al Aluminum+1%Si+4%Cu BD 483790-T |

| 194 | Balzers 90/92 Coating Materials Sputtering Targets Evaporation Sources Catalog. |

| 195 | Balzers 90-88749 LLS 801 Sputtering System Manual |

| 196 | Balzers BAK 642 Sputtering System |

| 197 | Balzers Coating Materials Sputtering Targets Evaporation Sources 84/86 Catalog. |

| 198 | Balzers D12/45216951 Remote Control for Wafer Sputtering System |

| 199 | Balzers LLS 801 Sputtering System Operating Manual |

| 200 | Balzers Manual Set Unaxis LLS 502 Load Block Metal Film PVD Sputtering System |

| 201 | Balzers MC 515 BK221410-T Magnetron For LLS 502 Sputtering System |

| 202 | Balzers Unaxis Sputter Target AITi Ring ARQ 131 M00-1074/1 01-342081 |

| 203 | Barium sputter target Ba 99.9% purity 2″ diameter x 0.25″ thick |

| 204 | Bayville chemical carbon sputtering target (99.99%) 2″ diameter 0.125″Thk AA-17 |

| 205 | Big End Bearings KOLBENSCHMIDT Sputtering BMW 2.5d 3.0d 24V M57D30 M51D25 E71 X6 |

| 206 | Big End Bearings KOLBENSCHMIDT Sputtering VW T5 Transporter Bus 2,5l Tdi Axe Axd |

| 207 | BIG END BEARINGS Sputtering KS VW Audi Seat Skoda 1, 9L TDI PD AJM AUY ATD atj |

| 208 | Big End Bearings without Cleats Sputtering Glyco 71-3904 0,25mm Oversized 1,2 |

| 209 | Bio-Rad Polaron E6700 Turbo vacuum coating ?sputter evaporation bell jar coater |

| 210 | BioRad Polaron E7000 Freeze Fracture Sputter Coater Vacuum Chamber Bell Jar |

| 211 | Bismuth Selenide , Bi2Se3 – Sputtering Target |

| 212 | Bismuth sputter target, 99.999% pure Bi, 2.00″ diam x 0.25″ thk |

| 213 | Bismuth Sputtering Target, 3.00″ D x 0.25″ thick, 99.999% pure |

| 214 | Bismuth Telluride, Bi2Te3 – Sputtering Target |

| 215 | Black Wheel Cap for 2021 2022 KIA Sorento for 20-inch Sputtering Wheel Rim |

| 216 | Bohemia Jihlava JS14071, 10-Inch Crystal Vase with Platinum Gold Sputtering |

| 217 | Bohemia Jihlava JS16914, 10-Inch Crystal Vase with Blue/Gold Sputtering |

| 218 | Bonfire Sheet Sputtering Sheet Bonfire Board Seat Heat Welding Authentic |

| 219 | Bonfire Sheet Sputtering Sheet Bonfire Board Seat Heat Welding Authentic |

| 220 | Boron sputtering target B 99.5% purity, 2″ diameter x 0.125″ thick |

| 221 | Boron, B – Sputtering Target |

| 222 | Brian CHAPMAN / Glow Discharge Processes Sputtering and Plasma Etching |

| 223 | BUHLER SPUTTERING TARGET 6333032265 LOPH-14120-001 Target 320x100x8 |

| 224 | Bumper Sticker “Our ’38 Ford Is Sputtering” 1938 Classic Collector 14″ |

| 225 | Burbank Sportscards – World’s Largest Selection |

| 226 | BZ-1730-21-A – Leybold Heraeus – CONTACT ELEMENT – FOR SPUTTERING 011/110 |

| 227 | Cadmium SEM Sputtering target: Cd 99.99% pure, 57mm diameter x 0.25mm thick |

| 228 | Cadmium sputtering target Cd 99.99% pure 2″ diam x 0.25″ thk |

| 229 | Cadmium Sulfide, CdS – Sputtering Target |

| 230 | Calcium (reactive) sputter target Ca 99.9% 2″ diam x 1/4″ thk |

| 231 | Calcium Fluoride, CaF2 – Sputtering Target |

| 232 | Calcium Manganate, CaMnO3 – Sputtering Target |

| 233 | Calcium Ruthenate, CaRuO3 – Sputtering Target |

| 234 | Calcium Ruthenium-Titanate, Ca(Ru0.5Ti0.5)O3 – Sputtering Target |

| 235 | Calcium Titanate, CaTiO3 – Sputtering Target |

| 236 | Canon / Anelva 912-7060 Sputter Ion/Noble Ultra High Vacuum Pump 400 L/sec |

| 237 | CANON / ANELVA C-7300,PVD, SPUTTERING SYSTEMS “2010 vintage” , wafer size 12″ |

| 238 | Canon Anelva 1015i Sputtering System – 6″ |

| 239 | CANON ANELVA Sputtering Equipment C-7530 HF |

| 240 | Canon/Anelva C7100 PVD, SPUTTERING SYSTEMS *SJ3 |

| 241 | Carbon SEM Sputtering target: C 99.999% pure, 54mm diameter x 1mm thick |

| 242 | Carbon sputtering target C 99.999% 2″ diameter x 0.25″ thick ACI ALLOYS |

| 243 | CdS, 99.99%, 18” x 3.5” x 0.250” Sputtering Target, Bonded Cu BP/I |

| 244 | Cerac Aluminum Al Sputtering Target 5″ x .25″ |

| 245 | Cerac Chromium Silicide, CrSi2 Sputtering Target 5.94″ x .253″ |

| 246 | Cerac Indium-Tin Oxide 5 ” high Purity Sputtering Target |

| 247 | Cerac Specialty Inorganics Titanium Oxide TiO2 Sputtering Target |

| 248 | Cerac Titanium Sputter Target 99.999% Pure |

| 249 | Ceramic Back Sputter Shield |

| 250 | CHIYODA GREEN SPUTTER RESISTANT TUBING PN# TE-10AFG-20 |

| 251 | CHROMA ET535/50M SPUTTER/HARD COATED |

| 252 | Chrome sputtering target Chromium 5 inch round Varian MDP |

| 253 | Chromium Cr Sputtering Targets – 2.00″ Diameter, 0.250″ Thick – Kurt J. Lesker |

| 254 | Chromium sputter target, Cr 99.95% pure, 2″ diameter x 0.125″ thick |

| 255 | Chromium sputter target, Cr 99.95% pure, 2″ diameter x 0.25″ thick |

| 256 | CIGS – Sputtering Target – for solar cells |

| 257 | Cisco Kid Topper Top Water Buzz Sputter Bait Muskie Pike Bass Black Gold |

| 258 | Clunk & Sputter by Muerte Pan Alley (CD, 2014) |

| 259 | Co/Fe Sputtering Target: 90/10 At% 3N5 2” x 3mm Thick |

| 260 | Cobalt Chrome sputter target Co/Cr 83/17 at%, 99.95% pure, 3.0″ dia x 6mm thk |

| 261 | Cobalt Co Sputtering Targets – 2.00″ Diameter, 0.250″ Thick – Kurt J. Lesker |

| 262 | Cobalt Iron Aluminum sputter targe Co2/Fe/Al 99.95% 2″ diameter x 0.125″ thick |

| 263 | Cobalt Iron Boron sputter target (Co/Fe/B 6:2:2 at%, 99.9%) 1.50″ diam 2mm thick |

| 264 | Cobalt Iron Boron sputter target, Co/Fe/B 99.9% pure, 2″ diam x 3mm thk |

| 265 | Cobalt Iron Zirconium sputter target Co/Fe/Zr 60/25/15 at% 1.0″ diam x 0.1″ thk |

| 266 | Cobalt Manganese Silicon sputter target, Co2MnSi heusler alloy, 2″ dia x 3mm thk |

| 267 | Cobalt sputter target, 99.98% pure, 2″ diameter x 0.125″ thick |

| 268 | Cobalt sputter target, Co 99.95% pure, 1.00″ diameter x 0.045″ thick. |

| 269 | Cobalt Titanium sputter target Co/Ti 1:1 At% 99.95% 2“ diam x 1/4” thk |

| 270 | Cobalt with Iron, Boron & Silicon mixture- Sputtering Targets |

| 271 | Cobalt, Co – Sputtering Target |

| 272 | Cobalt/Iron sputter target, Co/Fe 50/50 weight% 99.95%, 2.00″ diam x 0.125″ thk |

| 273 | Cobalt/Iron/Boron sputter target Co/Fe/B 60/20/20 4″ diam x 0.079″ thick |

| 274 | Cobalt-Iron sputter target: Co/Fe 50/50 At% 3” x 0.08” Thick |

| 275 | Colored Sputtering Paint Shower Curtain Abstract Graffiti Bathroom Accessory Set |

| 276 | COMPUTATIONAL EXPLORATIONS IN MAGNETRON SPUTTERING By E. J. Mcinerney |

| 277 | Connecting Rod Bearing Kit Rotary VW Audi TDI 1,9l 1z AAZ AFN ASV AHF AVG 71-384… |

| 278 | Connecting Rod Bearing kolbenschmidt magnetrons BMW 2.5d 3.0d 24v m57d30 m51d25 … |

| 279 | Connecting Rod Bearing kolbenschmidt magnetrons VW t5 TRANSPORTER VAN 2,5l TDI A… |

| 280 | Connecting Rod Bearing magnetrons Audi VW 1,9l 2,0l 2,5l TDI ARL AVF ASZ Bottle … |

| 281 | Connecting Rod Bearing magnetrons Audi VW 1,9l 2,0l TDI BOTTLE BKD BLB BMM BL… |

| 282 | Connecting Rod Bearing magnetrons BMW e36 e39 e46 e60 525 530 TDS 6zyl. Diesel m… |

| 283 | Connecting Rod Bearing magnetrons GLYCO Mercedes Diesel C-Class E-Class |

| 284 | Connecting Rod Bearing magnetrons GLYCO Racing VW Audi Seat 1,8l 2,0l 16v Turbo … |

| 285 | Connecting Rod Bearing magnetrons GLYCO VW AUDI SEAT SKODA 1,2 1,4 1,9 TDI |

| 286 | Connecting Rod Bearing magnetrons kolbenschmidt VAG VW AUDI SEAT SKODA 1,9 2,0 T… |

| 287 | Connecting Rod Bearing magnetrons KS 0,25mm VW Audi Seat 1,8l 2,0l 16v Turbo 16v… |

| 288 | Connecting Rod Bearing magnetrons KS Racing Audi 5zyl. 2,2l s2 rs2 s4 s6 3b ABY … |

| 289 | Connecting Rod Bearing Set Sputtering VW Audi Tdi 1,9l 1Z Aaz AFN Asv Ahf AVG |

| 290 | Connecting Rod Bearing Sputtering GLYCO Mercedes Diesel C-Class |

| 291 | Connecting Rod Sputtering Audi VW 1,9l 2,0l 2,5l Tdi Arl Avf Asz Bkd Bmm 71-3930 |

| 292 | Connecting Rod Sputtering Audi VW 1,9l 2,0l Tdi Azv Bkd Blb Bmm Blt Axc Aws |

| 293 | Connecting Rod Sputtering KOLBENSCHMIDT BMW 4Zyl. Diesel M47D20 318d 320d E39 |

| 294 | Connecting Rod Sputtering KOLBENSCHMIDT VAG VW Audi Seat Skoda 1,9 2,0 Tdi |

| 295 | Connecting Rod Sputtering Ks Racing Audi 5Zyl. 2,2l S2 RS2 S4 S6 3B Aby Adu Aan |

| 296 | Connecting Rod Without Cam Sputtering VW Audi 1,2 1,4 1,9 Pd GLYCO 71-3904 Pair |

| 297 | Connecting Rod Without Cam Sputtering VW Audi 1,2 1,4 1,9 Pd GLYCO 71-3904 Set |

| 298 | CONROD BIGENG BEARINGS +0.5MM FOR MERCEDES BENZ M 276 DE35 SPUTTER REPLACEMENT |

| 299 | Copper Magnesium sputter target: Cu/Mg 98/2 wt%, 99.9% pure, 3″ dia x 6mm thk |

| 300 | Copper Nickel sputter target Cu/Ni 55/45 at% 99.99%, 1.00″ dia x 0.125″ thick |

| 301 | Copper Oxide Sputtering Target CuO 99.995″ Pure 2″ x .1875″ thick +Backing Plate |

| 302 | Copper Oxide, Cu2O – Sputtering Target |

| 303 | Copper SEM Sputter target: Cu 99.995% pure, 57mm diameter x 0.25mm thick |

| 304 | Copper sputter target Cu 99.997% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 305 | Copper, Cu – Sputtering Target |

| 306 | Copper/Gallium/Indium sputter target Cu/Ga/In (32.9/11.3/55.8 wt%) 1.5″ x 0.15″ |

| 307 | Copper/Manganese sputter target Cu/Mn 86.5/13.5 at% 1.5″ dia x 0.125″ thk |

| 308 | Copper/Nickel sputter target Cu/Ni 95/5 at% 99.99% 1 inch diam x 1/8 inch thk |

| 309 | Cover Food Splash Guard Microwave Anti-Sputtering with Steam Vents Magnetic |

| 310 | Cover Microwave Oven Food Cover Anti-Sputtering Heat Resistant Lid Household |

| 311 | CPI CPW2870B10-47 Power Supply 27-158946-00 36kW Sputtering 460V Input PARTS |

| 312 | Crystal Goose 7 Oz Wine Glasses on a Long Stem with Gold and Platinum Sputtering |

| 313 | Crystal Goose 7.1 Oz. Wine Glasses on a Long Stem with Gold Sputtering |

| 314 | Crystal Goose 7.1 Oz. Wine Glasses on a Long Stem with Gold Sputtering |

| 315 | Crystal Goose 8 Oz. Wine Glasses on a Long Stem with Gold Sputtering |

| 316 | Crystal Goose 8.11 Oz. Wine Glasses on a Long Stem with Gold Sputtering |

| 317 | Crystal Goose Two Glass Salad Bowls with Golden Sputtering |

| 318 | CTI-Cryogenics 8113008 On-Board FastRegen Control Sputtering Module |

| 319 | CTI-CYROGENICS ON-BD FAST REGEN CONTROL SPUTTERING 8129948G001 T13-D6 |

| 320 | CuGa – Sputtering Target – 99.99% purity |

| 321 | CUSTOM SPUTTERING SYSTEM W/ 5 SPUTTERING SOURCE & 1 EVAPORATION SOURCE |

| 322 | CVC Products 2800 Load Lock Dual Process Chamber Sputtering System with Handler |

| 323 | CVC Products Inc 2800 Sputter Shields Shutter Segments Cathode Stations Cleaned |

| 324 | CVC Products Vacuum Sputter Deposition System ENI RF Generators ACG 10 |

| 325 | CZTS & CZTS-Se- Copper-Zinc-Tin-Sulfur-Selenium Sputtering Targets |

| 326 | DC/RF Dual-Head High Vacuum 2″ Magnetron Plasma Sputtering Coater |

| 327 | Delta sputter target: Aluminum Al 99.999%,vacuum sealed, 200mm x 0.25″ |

| 328 | Denton Explorer 14 Sputter 2 Target, RF Generator, Matching Network, Turbo Pump |

| 329 | Denton vacuum desk carbon rod accessory 120volt |

| 330 | DENTON VACUUM DESK II Sputter Coater SEM Thin Film Deposition |

| 331 | Denton Vacuum Desk II Sputter Coater SEM Thin film Deposition *Parts/Repair* |

| 332 | Denton Vacuum DESK II Sputter Coater w/ Carbon Coater and Accessories |

| 333 | Denton Vacuum Desk-1 Cold Sputter Etch Unit |

| 334 | Denton Vacuum Desk-1 Cold Sputter Etch Unit Sputter coater and DCP-1 module |

| 335 | Denton Vacuum DV-502A High Vacuum sputtering parts transformer power supply |

| 336 | Denton Vacuum DV-502A High Vacuum sputtering parts valves |

| 337 | Denton Vacuum II Sputter / Sample Coater SEM Sample Prep |

| 338 | Desktop Magnetron sputtering PVD coating machine for fuel cell electrode sputter |

| 339 | DEUBLIN ROTARY UNION FOR SPUTTER ASSY, AMAT 0190-40352 SP0326 |

| 340 | Disney Pixar Cars Dan Haulin’ dinoco 400 #92 Sputter Stop cab |

| 341 | Disney Pixar Cars Lot Mack Hauler Truck 1:55 Diecast Model Car Toys Loose |

| 342 | Disney Pixar Cars McQueen 1:55 Diecast Movie Collect Car Toys Gift Boy Loose |

| 343 | Disney Pixar Cars McQueen 1:55 Diecast Movie Collect Car Toys Gift Boy Loose |

| 344 | Disney Pixar Cars Sputter Stop Kmart Exclusive Collector Days 1 Racer #92 |

| 345 | DISNEY PIXARCARS/PISTON CUP SPUTTER STOP NO.92 DIECAST VEHICLE ON CARD |

| 346 | Duniway Stockroom Corp. IPC-0062 Varian Sputter Ion Pump Control Unit PARTS |

| 347 | Duniway Stockroom GIP/25-TAP-M Sputter Ion Pump 10-4 torr – 10-11 torr vacuu |

| 348 | Dysprosium sputtering target Dy 99.9% 2″ diameter x 0.125″ thick: ACI ALLOYS |

| 349 | Early Arbogast Hawaiian Sputter Fuss Spinner Spoon Fishing Lure |

| 350 | Edwards S150B Sputter Coater T8840 Au/Pd 60mm *1 w/ Outlet Mist Filter MF20 |

| 351 | Edwards S150B Sputter Coater Works |

| 352 | EDWARDSS150B SPUTTER COATER WITH EDWARDS #2 VACUUM PUMP |

| 353 | Electromagnet for Nordiko Sputtering System |

| 354 | ENI 791521 DCG100 sputter module |

| 355 | ENI DCG-100A 10kW DC Sputtering Plasma Power Supply/Generator DCG2D-A031100021I |

| 356 | ENI OEM-50N-11601 13.56 MHz RF Plasma Generator Solid State for Sputter Chamber |

| 357 | Eratron PPS 8210 2KV RS MF 10kW DC Sputtering Plasma Power Supply with Castors |

| 358 | Eratron PPS 8210 RS MF 10KW DC Sputtering Plasma Power Supply |

| 359 | Eratron PPS 8210 RS MF High Power Sputtering Plasma Power Supply Output: 10KW DC |

| 360 | Erbium sputter target: Er 99.9% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 361 | Ernest F Fullam Vintage Sputter Coater 5 Torr Vacuum Gage |

| 362 | ESPI Metals Monel KND2240 Sputter Target |

| 363 | ESPI Metals Tin Zn AI Sputtering Target .375″x4.75″x14.875″ Purity 5N |

| 364 | ESPI Metals Tin Zn Sputtering Target .375″x4.75″x14.875″ Purity 5N |

| 365 | Europium sputter target Eu 99.9% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 366 | EVAC Chain Clamp Sanitary Pipe Ultra Low Vacuum Sputtering Deposition Chamber |

| 367 | FEI DUNIWAY Sputter Ion Pump Module 4022 198 24924 |

| 368 | FERROFLUIDICS ROTARY FEED THROUGH STAINLESS STEEL 52-110007 Sputtering Vacuum |

| 369 | FERROFLUIDICS ROTARY FEED THROUGH STAINLESS STEEL 7467 52-10007M Sputtering |

| 370 | FIL-TECH G71PT .709″ PYREX TWIN TUNGSTEN FILAMENTS MRC STYLE SPUTTERING G-71-PT |

| 371 | FIL-TECH G71PT .709″ PYREX, TWIN TUNGSTEN FILAMENTS, MRC STYLE, SPUTTERING – NIB |

| 372 | Fire Force Enen no Shouboutai Flare & Sputter T-shirt Japan Limited Cosplay |

| 373 | Fireball Beach Disney Pixar Cars #92 Sputter Stop Sheldon Shifter 1:55 Diecast |

| 374 | FISHING LURE ARBOGAST SPUTTER FUSS |

| 375 | FISHING LURE FRED ARBOGAST 3″ SPUTTER BUG RED HEAD |

| 376 | Fison Ins Polaron SC7640 Auto/Manual High Resolution Sputter Coater – Made in UK |

| 377 | Fisons Instruments Polaron SC7610 Sputter Coater w/ Vacuum Chamber |

| 378 | Fred Abrogast Hawaiian Wiggler lure lot (5) Sputter Fuss 3/8 oz 1/2 oz |

| 379 | Fred Arbogast Hawaiian Fishing Lure – Sputter Fuss |

| 380 | Fred Arbogast Sputter Fuss Hawaiian Fishing Lure |

| 381 | Fred Arbogast Sputter Fuss Hawaiian Fishing Lure |

| 382 | Ga2TeO3 – Sputtering Target – 99.99% purity |

| 383 | GAS DISTR. PLATE SPUTTER, AMAT 0020-09933 |

| 384 | Ga-ZnO – Sputtering Target – 99.99% purity |

| 385 | GENERIC SQT-0054 SPUTTER TABLE CHUCK OSR24544 SQT0054 |

| 386 | Generic Water Cooled Jacket for Sputtering / Vacuum Bell Jar Chambers |

| 387 | Germanium sputter target Ge 99.999% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 388 | Germanium Telluride (GeTe) Sputtering Target, 3″ D x 0.125″ thick 99.999% pure |

| 389 | Germanium-antimony-tellurium sputter target Ge2Sb2Te5 99.999% 1″ diam x 5mm thk |

| 390 | Glass For Viewport UHV Sputtering |

| 391 | Glow Discharge Processes : Sputtering and Plasma Etching, Hardcover by Chapma… |

| 392 | Glow Discharge Processes : Sputtering and Plasma Etching, Hardcover by Chapma… |

| 393 | GLOW DISCHARGE PROCESSES: SPUTTERING AND PLASMA ETCHING By Brian Chapman |

| 394 | Glow Discharge Processes: Sputtering and Plasma Etching by Brian Chapman |

| 395 | Glow Discharge Processes: Sputtering and Plasma Etching, Chapman, CHAPMA-, |

| 396 | GLYCO Connecting Rod Sputtering Volvo C70 S40 S60 S70 S80 V40 V60 V70 XC40 XC60 |

| 397 | Glyco Main Bearing Connecting Rod Sputtering Thrust Washers VW Audi 1,8T 20V S3 |

| 398 | GLYCO Main Bearings Rod Bearing magnetrons Thrust Washers VW Audi 1,8t 20v s3 ba… |

| 399 | Gold SEM Sputter target: Au 99.99% pure, 54mm diameter x 0.1mm thick |

| 400 | Gold SEM Sputter target: Au 99.99% pure, 57mm diameter x 0.1mm thick |

| 401 | Gold Target for MNT-JS1600 Plasma Sputtering Coater 50mm dia x 0.1mm (99.999%) |

| 402 | GREAT CONDITION-Mattel Disney Pixar Cars *SPUTTER STOP*-Never Opened-RARE |

| 403 | Great Prices and Quality from DeCluttr. 3m+ Feedbacks |

| 404 | Growth of High Permittivity Dielectrics by High Pressure Sputtering |

| 405 | GUND – SPUTTER THE BEAVER – #1553 – 9″ |

| 406 | Gund 1992 SPUTTER BEAVER w Bouquet & Tags 1553 |

| 407 | Gund 1992 Sputter Beaver White Pink Bouquet Stuffed Animal Plush Rare |

| 408 | H shaft connecting rod g60 steel connecting PG 1h + Connecting Rod Bearing magne… |

| 409 | Hafnium , Hf – Sputtering Target – 99.95% purity |

| 410 | Hafnium Oxide, HfO2 – Sputtering Target – 99.95% purity |

| 411 | Hafnium sputter target 99.99% pure Hf (<0.2% Zr) 2.00″ diam x 0.25″ thk |

| 412 | Hafnium sputter target, 99.9+% pure, 1.50″ diameter x 0.125″ thick |

| 413 | Hafnium/Silicon Hf/Si 1:1 at%, sputter target 4″ diam x 7mm thk, 99.9% pure |

| 414 | Handbook of Sputter Deposition and Technology HCDJ Wasa Hayakawa |

| 415 | Handbook of Sputter Deposition Technology : Fundamentals and Applications for… |

| 416 | Handbook of Sputter Deposition Technology : Fundamentals and Applications for… |

| 417 | Handbook of Sputter Deposition Technology: Fun.. 9781437734836 by Wasa, Kiyotaka |

| 418 | Handbook of Sputter Deposition Technology: Fund, Wasa.= |

| 419 | Handbook of Sputter Deposition Technology: Fundamentals and Applications for |

| 420 | HANDBOOK OF SPUTTER DEPOSITION TECHNOLOGY: PRINCIPLES, By Kiyotaka Wasa VG |

| 421 | Handbook of Sputter Deposition Technology: Principles, Technology and… |

| 422 | Hawaiian Sputter Fuss 2 1/2″ Long 5/8 0z. Yellow with multi color skirt |

| 423 | High Power Impulse Magnetron Sputtering : Fundamentals, Technologies, Challen… |

| 424 | High Power Impulse Magnetron Sputtering : Fundamentals, Technologies, Challen… |

| 425 | High Power Impulse Magnetron Sputtering: Fundam, Lundin, Daniel,, |

| 426 | High Purity 99.999% 5N Al Aluminum Sputtering Target Diameter 2” Thick 5mm |

| 427 | High Purity 99.999% 5N Al Aluminum Sputtering Target Diameter 70mm Thick 5mm |

| 428 | High Purity 99.999% 5N Al Aluminum Sputtering Target Diameter 70mm Thick 5mm |

| 429 | High Vacuum Deposition “Sputtering” Coating Machine |

| 430 | High Vacuum Heated Sensor Viewport / RGA Sputtering Analysis |

| 431 | Holmium sputter target Ho 99.9% 2″ diameter x 0.25″ thick: ACI ALLOYS |

| 432 | Honeywell 0190-20139/D 300mm Sputtering Target AMAT Applied Materials |

| 433 | Honeywell 037-0173-25 Sputtering Target 300mm |

| 434 | HONEYWELL 080796 Sputtering Target 5N5 TI 0437x11625x12555 BPM |

| 435 | HONEYWELL 084795 Sputtering Target 5N Al5Cu 7830x11640x13050 |

| 436 | Honeywell 090113 SPUTTERING TARGET 5N5 Al1Si.5Cu 12.555X11.625X1.600IN |

| 437 | Honeywell Sputtering Products 5N Ti Titanium) Target 20.625X17.478X1.000X0.500IN |

| 438 | Honeywell Sputtering Vectra Coil TSVCTISET-07935 OPENED READ |

| 439 | Honeywell target, M2000 sputtering, 59 Ti, .500X4.460X13.050 inches, PI000-04462 |

| 440 | Honeywell target, M2000 sputtering, 59.5Ti/.5CU, 4.460X11.64X13.050, PI000-05076 |

| 441 | Honeywell target, sputtering, M2000 49.5 Ti,.500X4.460X13.050inches, PI000-04462 |

| 442 | HONEYWELL TSENAL-MOX-06514 Sputtering Target 595AL5Cu 1910x11300x14495 |

| 443 | Honeywell TSQUALWDX-07821 Sputtering Target 59Al/1Cu 7.830×11.640×13.050″ |