Description

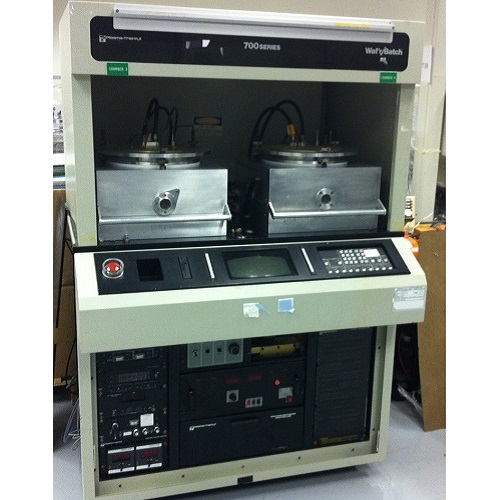

Model: Matrix 303 Plasma Etcher semiconductor process equipment

Photos: Download here

Category: Etcher

Original Equipment Manufacturer: Matrix Integrated Systems, Inc

Condition: AS IS,Where Is (Refurbished by seller is optional with warranty, installation and service if necessary)

Wafer Size: 6 inch configuration.

Valid Time: Subject to prior sale without notice

Lead Time: Ready to go.

Location: Silicon Valley, CA, U.S.A.

Warranty: No.

Refund: No

Matrix 303 plasma etcher (dry etcher) semiconductor process equipment General Description (Reference only)

1.1 Matrix 303 dry etcher General Description

The Matrix 303 is an electro-mechanical production system used to etch materials such as nitride, oxide, polysilicon,etc. from the surface of silicon or other substrates. Each wafer is processed individually by means of a chemical reaction induced by a gas plasma. The system consists of the following major assemblies:

1.1.1 Matrix 303 dry etching Main console

Process Module

Operator Interface Module

Wafer Transport Module

Card Reader Module

Elevator Module

Microprocessor Control Module

1.1.2 Matrix 303 plasma etching Power Supply Console

RF Generator

DC Supply

AC Distribution

Gas Distribution Panel

Temperature/Pressure Control

Module

1.1.3 Matrix 303 plasma etch vacuum Pump (Optional)

Vacuum Hose and Connectors

Ballast Assembly

1.2 Matrix 303 plasma etcher Features

The Matrix 303 offers the following features:

* SINGLE WAFER PROCESSING

* WAFER CAPABILITY: 4 11 (100 mm), 5 11 (125 mm) and 6 11 (150 mm)

* CASSETTE HANDLING

* WAFER HANDLING: Robotic pick and place

* MICROPROCESSOR CONTROLLED

* MONOCHROMATOR FOR ENDPOINT DETECTION (Standard)

* TEMPERATURE CONTROL: Provides temperatures of up to 160°C for process stability

* DOT MATRIX PLASMA DISPLAY SCREEN

* MODULAR DESIGN

* PROGRAMMABLE DIAGNOSTICS

* PHASE MAGNITUDE TUNER

* BUTTERFLY-TYPE PRESSURE CONTROLLER

* PINS UP/DOWN TO HEAT WAFER

* MULTI-STEP PROCESSING

1.3 Matrix 303 semiconductor process equipment Principles of Operation

The system is process driven by user friendly commands or by the insertion of a programmed magnetic card. It functions in the following sequence:

1.3.1 Matrix 303 Loading Transport

One wafer at a time is robotically picked from a cassette, transported to and deposited in the reaction chamber. The chamber door closes and the chamber is automatically sealed from the atmosphere.

1.3.2 Matrix 303 Process

Through a series of microprocessor controlled operating steps, the wafer is processed, i.e., the desired material is etched. The processing steps include the following:

a) The chamber is evacuated to a preset pressure.

b) Gas flow to the chamber is initiated at a predetermined and process-selected controlled rate, and a process selected pressure is maintained.

c) A gas plasma is produced by exposing the appropriate gases to radio frequency energy from a generator operating at a frequency of 13.56 MHz.

d) The gas plasma reacts with the material to be etched to form gaseous byproducts. These byproducts are then removed from the chamber by the vacuum pump.

e) A monochromator is used to monitor the plasma and determine the process endpoint. Either monochromator or timed endpoint can be used.

1.3.3 Matrix 303 Process Deactivation

When the processing of the wafer is completed, the power and gas flow are stopped. Nitrogen is then used to restore the chamber to atmospheric pressure.

1.3.4 Matrix 303 Unloading Transport

The wafer is robotically returned to its original position and orientation in the cassette. Subsequent wafers are similarly selected, transported, processed and returned to the cassette.

1.4 Matrix 303 Physical Specifications

| Main Console | Power Supply Console | overall | |

| WIDTH | 25″ | 25″ | 25″ |

| DEPTH | 28″ | 28″ | 28″ |

| HEIGHT | 22″ | 36″ | 58″ |

| WEIGHT | 100 lbs | 310 lbs | 410 lbs |

All the Matrix 303 Plasma etcher semiconductor process equipment trademarks belongs to Matrix Integrated Systems, Inc, the original equipment manufacturer. All rights reserved.