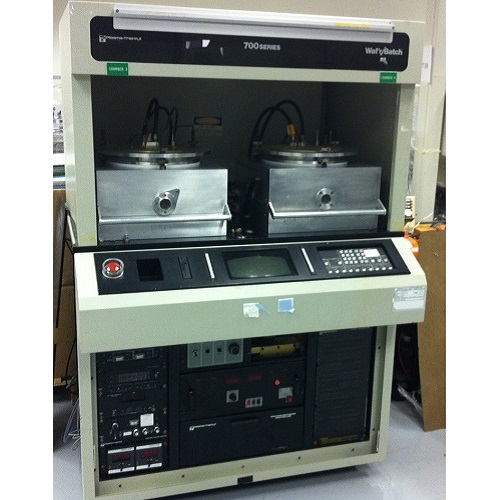

Description

New Plasma Asher Descum Equipment for Compound materials

The New Plasma Asher/Descum equipment represents the industry standard in single-wafer photoresist removal and the mainstay of the highly successful plasma descum system for GaAs, SiC, GaN,InP,GaInP etc. Developed in cooperation with many of the world’s leading compound materials IC producers, the New Plasma Asher/Descum equipment has been designed for optimum performance, non-parts obsolescence, and low cost of ownership.

The New Plasma Asher/Descum equipment is a plasma ash/descum system with an integrated robotic wafer transfer engineered for fragile substrates. It is controlled by advanced Control Software. It is uses RF generated plasma to ash the photoresist.

The wafers to be processed are in a cassette and placed on the cassette station. The operator selects a recipe and starts the process run. The integrated solid robot takes a wafer from the cassette and places it on the centering station. It then places the wafer into the chamber. Once the wafer has been processed, it is returned to the cassette.

Compared with other plasma asher descum systems, the New Plasma Asher/Descum equipment is more robust, more reliable and to modernize many of the key electronic components.

Plasma Asher Descum Systems Applications :

-

Photoresist Stripping

-

High dose implant (As+, B+, P+)

-

Rework

-

Post-polysilicon etch

-

Post-metal etch

-

Post-oxide etch

-

-

Controlled Resist Removal

-

Post-develop descum (pre-etch)

-

Dry/wet process capability

-

Uniformity capability (<5% 1σ)

-

-

GaAs, InP wafer Strip and Descum

-

Thin Film Head Resist Cleaning

-

Opto-Electronic Devices Cleaning

-

MEMS (Micro Systems Technology)

Key Features of the new plasma asher descum equipment:

- Production proven for more than 40 years for compound materials wafer dur to much better performance.

- Designed with III-V Production in mind!

- Downstream chamber structure.

- The integrated solid robotic wafer transfer is much more reliable .

- The control boards were redesigned with modern components and added features.

- The temperature control system for heating the chuck uses the Eurotherm controller. If the software detects the temperature is not within tolerance, it will turn off the current to the chuck heater and abort the process.

- Designed for 2” to 6” circular wafers. 8 inch is also optional.

- A light spectrum monitor (optional) is used to determine the endpoint by monitoring the illuminated intensity of the plasma.

- Wafer centering/cooling station.

- NO OBSOLETE PARTS.

- Industrial grade computer, touch screen GUI, and large hard disk drive.

- Small Footprint

Software Features

- Automated calibration of all subsystems from within the control software. This allows faster, easier calibration, leading to enhanced process results.

- Recipe creation. It features a recipe editor to create and edit recipes to fully automate the processing of wafers inside the chambers.

- Validation of the recipe so improper control sequences will be revealed.

- Storage of multiple recipes, process data and calibration files so that process and calibration results can be maintained and compared over time.

- Passwords provide security for the system, recipe editing, diagnostics, calibration, and setup functions.

- Simple and easy to use menu screens which allow a process cycle to be easily defined and executed.

- Troubleshooting features which allow engineers and service personnel to activate individual subassemblies and functions independently of other subsystems.

- The control software runs on almost any Pentium class PC computer with a parallel (printer) port. The computer interfaces to the system with only 1 cable, the control interface cable. There is also an interface cable to the robot controller. There is also an interface cable for the Eurotherm controller.

- The interface board inside the machine that translates the computer commands to control the machine has a watchdog timer. If this board looses communication with the control software, it will shut down all processes and halt the system until communication is restored.

Safety Features

The system incorporates several features to prevent damage to wafers or injury to personnel.

- There is a watchdog timer on the interface board. This turns off the process parameters if the communication between the computer and the system is interrupted or the software freezes.

- The RF system is interlocked to prevent their inadvertent operation when the chamber door is open.

- Pneumatic: The pneumatics is used to operate the Positive Shut-off valves and the chamber door. If there is no air pressure, the shut-off valves will close. If the power is removed from the system, then the pneumatic gas valves close automatically.

- EMO (Emergency Off): When the EMO is depressed, the power to the entire machine is turned off.

- Water Flow Switch: The water needs to flow at the recommended rate that is specified in the Installation manual. When a process starts, it will check the water flow rate. If the flow rate drops below this, the process will not run and an alarm will be issued.

Please contact us if you are interested in the New Plasma Asher/Descum equipment .Appreciate your time.

ID-220

“>KEYWORDS:Rapid Thermal Process, Modular Process Technology, Rapid Thermal Processing, Rapid Thermal Anneal, Rapid Thermal Annealing, Rapid Thermal Oxidation, Rapid Thermal Nitride, RTA, RTP, RTO, RTN,, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, AG210, AG310, AG 410, AG610, AG 610I, AG Associates, Heatpulse 210, Heatpulse 410, Minipulse 310, Heatpulse 610, Heatpulse 610I, AG Heatpulse 410, AG Heatpulse 610, AG Heatpulse 210, AG Minipulse 310, 4100 , 4100S 4108, 8108 ,8800, 8800i, Atmospheric Rapid Thermal Process, Vacuum Rapid Thermal Process, Furnace, Oven, Thermal Furnace, Thermal Process, Thermal Processing,JIPELEC, ag2146,JetClip,JetStar, AST SHS2000, AST STEAG 2800, ssintegration, Rapid Thermal Oxide,JetFirst ,Mattson, annealsys, heatpulse ,ag 2146,Koyo Thermo Systems,AST STEAG-MATTSON 2800, STEAG-MATTSON 2900, STEAG-MATTSON 3000, heat pulse, Solaris, Eclipse ,modularpro, RLA-1000, AG Heatpulse, rapid thermal processor, Steag AST SHS2000, Solaris 75, Solaris75,STEAG Electronic Systems ,eng-sol, Annealsys, RLA-3000, Engineering Solutions ,Solaris 150, Rapid Thermal Annealer , AS-Master ,modularpro,RTO ,Modular Process Technology, Solaris150,AS-One,AS-Micro, ADDAX, JetFirst, JetLight, JetStar, MPT-600S,MPT-800S, MPT-600XP, MPT-800XP, MPT-3000, Jipelec Jetfirst 150,Jipelec Jetfirst 200, JETFIRST 100,AnnealSys AS-One, RTP-3000, ULVAC, Ulvac Technology MILA 3000 ,Rapid Thermal Annealing, ULVAC RTA-2000,ULVAC RTA-4000,ULVAC RTA-6000,ULVAC RTA-8000,ULVAC RTA-12000, EasyTube® 3000EXT, CVD Equipment Corporation, Dr. Eberl MBE-Komponenten GmbH, AO 600,Rapid Thermal Annealing System,MBE Components,MBE Systems,OCTOPLUS 300,OCTOPLUS 400,OCTOPLUS 500,OCTOPLUS 500 EBV,OCTOPLUS 600,OCTOPLUS 600 EBV,OCTOPLUS-O 400,Thin Film Systems,Organic Deposition System,Rapid Thermal Annealing,MBE Components,Thin Film / CIGS / CZTS / CdTe,ECM, Annealsys AS-Premium, Annealsys Zenith-100, Annealsys AS-One, Annealsys AS-Master, Jipelec JetStar, Annealsys AS-Micro, Jipelec JetLight, Jipelec JetFirst 100, Jipelec JetFirst 200, Jipelec JetFirst 300, CreaTec Fischer & Co. GmbH, Rapid Thermal Anneling System, Mini MBE System,Growth System, Research Linear Transfer System,RTA System,UHV Shuttle System, SemiTEq JSC, Molecular-Beam Epitaxy Systems (MBE),PVD Systems,RTP & RTA Systems,ICP/RIE/PECVD Systems,Components and accessories, STE RTP150, STE RTA100, STE ICP200 , ADVANCE RIKO, Inc., RTP-mini, Atmospheric Thermoelectric Module Evaluation System F-PEM,Mini Lamp Annealer MILA-5050,infrared lamp heating system, ULTECH CO.LTD,Real RTP-100,Real RTP-100,Real RTP-150,Real RTP-Mini,SPUTTER,DRY ETCHER,PECVD,ALD,E beam evaporator,Thermal Evaporator, SJ High Technology ,Tube RTA,R-8160,drawer type RTA, R-401, Dai-ichi Kiden Co.,Ltd., Combustion furnace,High vacuum heating system,Vertical high temperature heating system,Induction heating system(elevating),Ultra high temperature heating system, Koyo Thermo Systems Co.,Ltd., Premtek Technology Co, 技鼎股份有限公司,技鼎股份有限公司,VF-5900 300mm Large Batch,VF-5700 300mm Mini Batch,VF-5300,8 inch,Large Batch,VF-5100,8 inch,Wide-Range Batch,VF-3000,8 inch,Low-Cost Mini Batch,VF-1000,Small Production and R&D,VFS-4000,Large Bore Vertical Furnace,Koyo Thermo Systems Co.,Ltd.,Model 200 Series Horizontal Furnaces for Mass Production and Experiments,Model 206A Horizontal Furnace for PV Production ,Model 206A Horizontal Furnace for PV ,Production,RLA-3100 Lamp Annealing System for Rapid Thermal Processing,RLA-1200 Lamp Annealing System for Rapid Thermal Processing,RLA-1200 Lamp Annealing System for Rapid Thermal Processing,SO2-12-F Heated-air Circulating Type Clean Oven for 300-mm Wafers,CLH Series High-Temperature Clean Ovens,CLH Series High-Temperature Clean Ovens,VFS-4000 Large Bore Vertical Furnace,VF-5300HLP Activation Annealing Furnace,VF-5300H Vertical Furnace for Gate Insulating Film Formation,VF-5300H Vertical Furnace for Gate Insulating Film Formation,RLA-4106-V Lamp Annealing System for Contact Annealing,RLA-4106-V Lamp Annealing System for Contact Annealing,VF-3000HLP Activation Annealing Furnace, VF-3000HLP Activation Annealing Furnace,VF-3000H Vertical Furnace for Gate Insulating Film Formation,VF-3000H Vertical Furnace for Gate Insulating Film Formation,RLA-3100-V Lamp Annealing System for Contact Annealing,RLA-3100-V Lamp Annealing System for Contact Annealing,Rapid temperature rise annealing furnace RTP_Table ,RTP_Table type rapid temperature rise annealing furnace,Rapid temperature rise annealing furnace RTP_SA ,RTP ,semi-automatic rapid temperature rise annealing furnace,Rapid temperature rise annealing furnace ,RTP_Auto ,automatic rapid temperature rise annealing furnace,RTP600V,RTP600Z,RTP500Z,RTP500V,RTP500SV,快速退火炉,北京东之星应用物理研究所,快速升溫退火爐,estarlabs,Glovebox+PVD,2D material CVD,LPCVD & Furnace,Vacuum Sintering Furnace,RTP,Plasma Doping (PDS),ASHER,Wet bench,Crystal Si solarcell. We are a leading manufacturer of Rapid Thermal Processing and Direct Liquid Injection Deposition systems. We are a top supplier for MEMS, sensors, optoelectronics, telecommunication, power and discrete device manufacturing. Labs worldwide use our machines for the development of semiconductor, photovoltaic and nano-technology components. Rapid Thermal Processing or Rapid Thermal Annealing (RTP/RTA) is a semiconductor manufacturing process which provides a way to rapidly heat samples to high temperatures to perform short processes on a timescale of a few minutes maximum. Such rapid heating rates are performed by high intensity lamps (e.g. near-infrared light sources – Tungsten-halogen lamps) controlled by pyrometer and thermocouples that measure the sample temperature. Cooling must also be perfectly controlled to prevent dislocations and sample breakage. Rapid Thermal Processing was originally developed for ion implant anneal but has broadened its application to oxidation, silicide formation, chemical vapor deposition, and advanced applications such as modifying the crystallographic phase of elements, compounds or alloys to enhance properties, lattice interface or stress relaxation. RTP is a flexible technology that provides fast heating and cooling to process temperatures of ~200-1300°C with ramp rates typically 20-200°C/sec, combined with excellent gas ambient control, allowing the creation of sophisticated multistage processes within one processing recipe. We are extensively used in semiconductor device manufacturing for changing electrical or physical properties of a material (conductivity, permittivity, densification, or contamination reduction). Soak, spike, or millisecond anneals and thermal-radical oxidation are applied to different applications. The choice of technology depends on several factors, including the tolerance of the device to withstand a certain temperature/time exposure at a particular point in the manufacturing sequence. Applied’s portfolio of lamp- , laser- and heater-based systems encompasses the full range of anneal technologies, offering extendible solutions to such advanced-node challenges as pattern loading, thermal budget reduction, current leakage, interface quality optimization, and high-productivity treatments.Tokyo Electron Limited Kokusai Electric ASM Naura Thermco Systems CETC48 JTEKT Thermo Systems Corporation Amtech Systems, Inc Ohkura Tystar Sunred

“>快速退火炉,速升溫退火爐,保护气氛快速退火炉,保護氣氛快速退火爐,快速退火爐,红外灯加热,红外灯快速退火,卤素灯加热,高温计,红外高温计,等离子去胶机,等离子刻蚀,深刻蚀,各向同性,各向异性,等离子清洗,溅射台,蒸发台,磁控溅射台,直流电源溅射,高频溅射,自动刻蚀机,自动去胶机,手动去胶机,手动刻蚀机,干法去胶机,湿法去胶机,干法刻蚀机,湿法刻蚀机,半导体设备,半导体旧设备,半导体中古设备,半导体前道工艺设备,半导体后道工艺设备,半导体前道设备,半导体后道设备,半导体量测仪器,半导体量测设备,美国制造,紅外線燈加熱,紅外線燈快速退火,鹵素燈加熱,高溫計,紅外線高溫計,等離子去膠機,等離子蝕刻,深刻蝕,各向同性,各向異性,等離子清洗,濺射台,蒸發台,磁控濺射台,直流電源濺射,高頻濺射,自動蝕刻機,自動去膠機,手動去膠機,手動蝕刻機,乾式去膠機,濕式去膠機,乾法蝕刻機,濕蝕刻機,半導體設備,半導體舊設備,半導體中古設備,半導體前道製程設備,半導體後道製程設備,半導體前道設備,半導體後道設備,半導體量測儀器,半導體量測設備,美國製造,Plasma Asher, Plasma Descum, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Matrix 105, Matrix 205, Matrix 303, Matrix 403,Matrix 106,Matrix 104, Matrix 102,Matrix 101, Matrix 10, System One Stripper, Model 105, System One Etcher, model 303, model 403,Matrix 1107, Plasma Etcher, Plasma Etching, Dry Etching, Dry Clean Plasma Asher, Plasma Descum, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Branson/IPC 2000, Branson/IPC 3000, Branson/IPC 4000, Barrel Asher, Barrel Etch, Barrel Etcher, Plasma Asher, Plasma Descum, Dry Clean, Downstream Asher,Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Gasonics Aura 1000, Gasonics Aura 2000, Gasonics Aura 3000, Gasonics L3510, Gasonics Aura 3010, Plasma Etcher, Plasma Etching, Dry Etching, Dry Clean,Gasonics AE 2001, Gasonics AE 2000LL Plasma Etcher, Plasma Etching, Dry Etching, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Plasma RIE ,Reactive Ion Etch System, Reactive Ion Etch System, Tegal 901e, Tegal 903e, Tegal 901e TTW, Tegal 915,Tegal 701,Tegal 703,Tegal 801,Tegal 803,Tegal 981e,Tegal 903e,Tegal 915, Tegal 965, Tegal 405, Tegal 401 Plasma Etcher, Please Etching, Dry Etching, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Lam AutoEtch 490, Lam AutoEtch 590, Lam AutoEtch 690, Lam AutoEtch 790, Lam Rainbow 4400, Lam Rainbow 4420, Lam Rainbow 4428, Lam Rainbow 4500, Lam Rainbow 4520, Lam Rainbow 4528, Lam Rainbow 4600, Lam Rainbow 4620, Lam Rainbow 4628, Lam Rainbow 4700, Lam Rainbow 4720, Lam Rainbow 4728, Plasma Etcher, Plasma Etching, Dry Etching, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Gasonics AE 2001, Microwave Etcher, Microwave Plasma Etcher, Microwave Etch, Downstream Plasma Etch Enviro,ENVIRO-1XaENVIRO-1Xa ,2CENVIRO-Optima,Luminous NA,NA-8000NA-1300NA-1500 ,Multifilm,NE-550EXaNE-950EX, APIOSNE-5700Deep, Oxide Etching ,NLD-570EXaRISE System,RISE Series,Cluster Systems,SME SeriesuGmni Series,SRH SeriesULDiS Series,SMV-500FRoll-coater,SPW SeriesIn-line Systems,SIV SeriesSDH-4550LR&D,CS-200, 300mm,ENTRON-EXENTRON-EX2,Evaporation Roll Coater,EW SeriesR&D/Pilot Production,Ei-5In-line Systems, Ei-H series,Si Processing,IMX-3500SOPHI-200/260 ,SiC,IH-860,Brazing Furnace,FB SeriesFHHn series ,Vacuum Sintering,FSC SeriesVacuum,Induction Melting,FMI Series,Vacuum Heat Treatment,FHB-60CFHV Series,Single-Substrate,CC Series,CME Series,In-line Systems, ULGLAZE Series,Lyophilizer,DFB Series,Micropowder Dry, UPD-400D,FM Series,DFR Series,Centrifugal Type,CEH-400B,ULVAC Perkin-Elmer 4400, Perkin-Elmer 4410, Perkin-Elmer 4450,Perkin-Elmer 4480, Perkin-Elmer 2400, Perkin Elmer 4400, Perkin Elmer 4410, Perkin Elmer 4450,Perkin Elmer 4480, Perkin Elmer 2400, Sputter, Magnetron Sputter, Diode Sputter, DC Sputter, RF Sputter, DC Magnetron Sputter, RF Magnetron Sputter, Co-sputter, Reactive Sputter, MRC, MRC 603, MRC 903, MRC 602, MRC 902, MRC 604, MRC 904, MRC 924, Plasma Etch, Dry Clean, Bias Function, Cathode, Load lock, Degas, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment,, Thin Film, Metal Thin Film, Thin Film Deposition, PVD, Physical Vapor Deposition Nordson MARCH Plasmatreat Bdtronic Panasonic PVA TePla Diener Electronic Vision Semicon Samco Inc. Tantec SCI Automation PINK GmbH Thermosysteme Plasma Etch Shenzhen OKSUN. Plasma Surface Treating Equipment : Nordson MARCH, bdtronic, Diener electronic, AcXys Technologies, Europlasma, ME.RO, Tantec, Plasmatreat, Plasma Etch, PINK GmbH Thermosysteme, Kalwar Group, Arcotec, Shenzhen OKSUN