Description

Fab Line Equipment and Product Info. for RF/Microwave Si BJT Power Devices & Pallets , RF/Microwave Silicon Diodes , MEMS Devices

Valid Time: Subject to prior sales without notice. Appreciate your time!

Info in detail: download

Video for your reference: Link at WIX

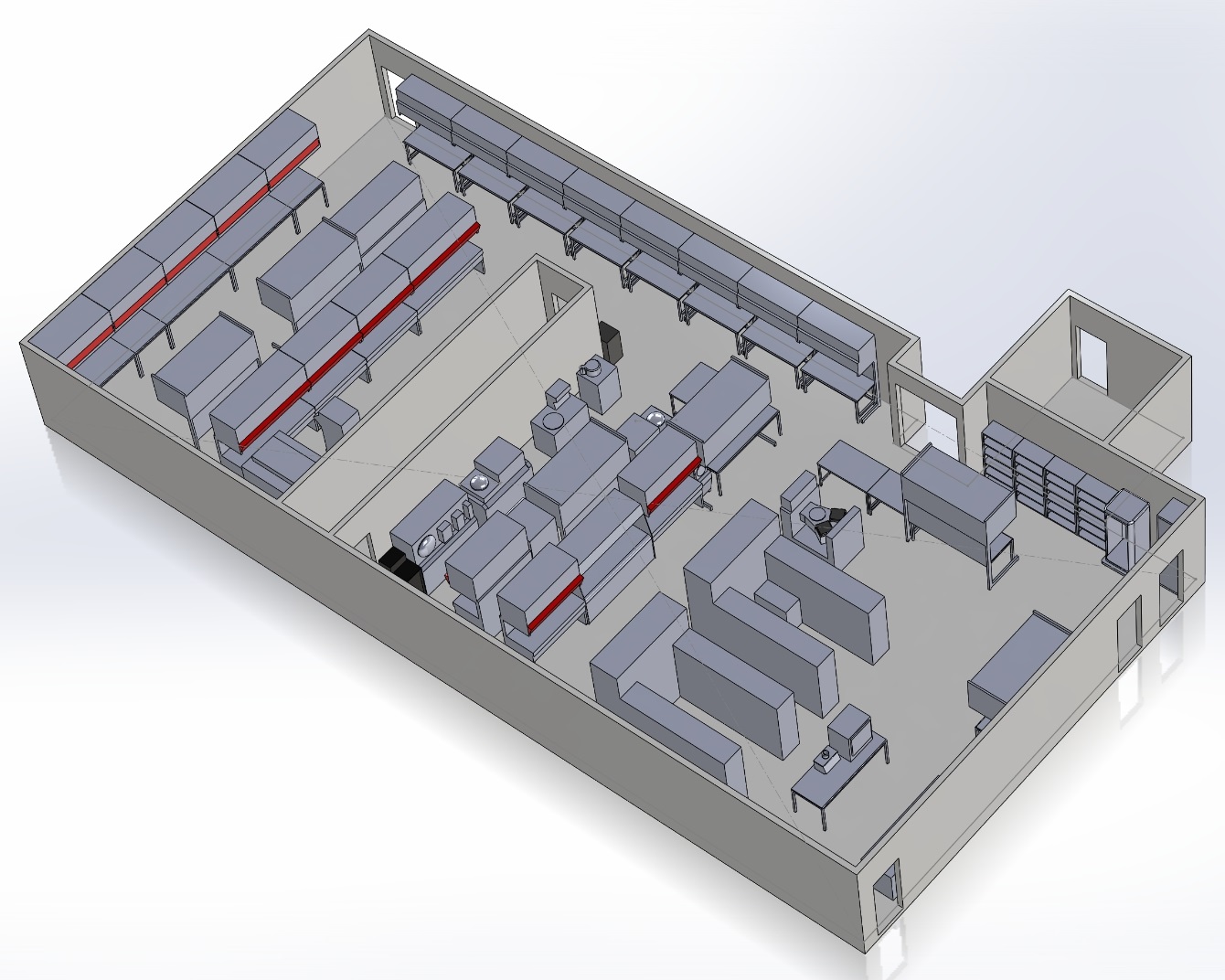

Name: RF Fab Line

Located: Silicon Valley , CA USA.

Status: Fab was shut down in 2021. All equipment were deinstalled and move to the storage at Silicon Valley in December, 2021. Equipment were plastic wrapped, metal banded, strapped and on skids/pallets(Heat treated already).

Info on products: The deal includes products design sheets , run travelers, recipes on the equipment.

Fab History and Capability: There are 5 product families that this fab produced. The site mostly used the 3” and 4” wafers, and they can produce between Qty 1,000 and 10,000 components per 3” wafer depending on the product family. This site only ran a single shift as well and WIP level was about 800-1000 wafers per month. A new owner can ramp up by running 2-3 or more shifts and have been utilization. Also can add more systems to increase throughput.

About 90% of the equipment is capable of 6” and even some is capable of 8” such as the AMAT and MRC’s as an example. This site never ran 8”, but they did run some lower quantities of 5” and 6” over the years. There are 18 tubes of capacity on the furnace stacks. 3 of them are LP (low pressure) and 3 of them are also set up for 6”. The equipment set is older and was well maintained, they exceed their numbers on the production so didn’t ramp up. They did talk about a few times but it never happened officially. This fab made a lot of money just on the 5 product families they produced. With some minor reconfiguration this fab could produce a lot of different by similar products. Or it could be converted and run SiC or GaN, or MEM’s if so desired.

Equipment List:

| # | Type | Vendor | Model # | Purpose |

| 1 | P5000 | AMAT | P5000 | PECVD |

| 2 | Particle Counter | FSM | 8800 | Particle count |

| 3 | Etcher | PlasmaLab | Plasma Etch | |

| 4 | PVD | MRC | 902M | 2 Target PVD |

| 5 | PVD | MRC | 902M | 2 Target PVD |

| 6 | PVD | MRC | 603C | 3 Target PVD |

| 7 | Ellipsometer | Rudolph | Auto-EL | Measurements |

| 8 | CV Junction | MDC | 490 | Epi Reader |

| 9 | Thin Film Meas | Metricon | 2010M | Measurements |

| 10 | Measurements | Nanometrics | 010-0180 | Measure Thin Film |

| 11 | Thin Film Meas | Filmetric | 205-6073 | Measure Thin Film |

| 12 | Surface Profiler | Tencor | Alpha 500 | Thickness Meas |

| 13 | Plasma Etcher | Technics | Planar Etch II | Plasma Etch |

| 14 | Plasma | Technics | 500-II | Asher |

| 15 | Stepper | GCA | ALS 200 | Aligner |

| 16 | Measurements | Micro Metric | Microline 100 | CD Measurements |

| 17 | Microscope | Leitz | Inspection | |

| 18 | Microscope | Zeiss | 4727100000/01 | Inspection |

| 19 | 3″ Scrubber | C&D | custom built | wafer scrubber |

| 20 | Tempress | LPCVD/Diff | 8 Stack | Furance |

| 21 | Tempress | Diffusion | 8 Stack | Furnace |

| 22 | HMDS | YES | LPIII | hmds |

| 23 | HMDS | YES | LPIII | hmds |

| 24 | Probe Station | Baush and Lomb | DC Measurements | |

| 25 | Resist Coater | SVG/C&D | N/A | Coat Resist |

| 26 | 9 Sinks with rinser | rinse and dry wafers | ||

| 27 | 8 wafer dryers | Semitool | Drying wafers | |

| 28 | 18 LFH | Fab | ||

| 29 | 18 Lab Tables | Fab | ||

| 30 | Chemial Storage | Yellow Cabinet | 2 Target Chemial Storage | |

| 31 | 5 Chemical Carts | Wet Bench | ||

| 32 | Particle Monitor | PMS | Fab Counter | |

| 33 | Evaporator | CVC? | Manual load | Metal evaporator |

| 34 | Denton | Sputter | Sputter | |

| 35 | Genesis | Microstar | Vac Oven | Vacuum Oven |

| 36 | HFS | DZF-6020-T | Vac Oven | Vacuum Oven |

| 37 | SEM | Hitachi | 800 | SEM |

| 38 | Wafer Sorter | Nex Gen | 1034XS D45 | |

| 39 | Wafer Sorter | Nex Gen | 1034XS | |

| 40 | Oven | Blue M | 5 | |

| 41 | TGO | Honeywell | CM4 | |

| 42 | Chiller | Infinity | ||

| 43 | Chiller | Infinity | ||

| 44 | Desiccators | Unknown | qty 6-8 |

OEM-Line-3