Description

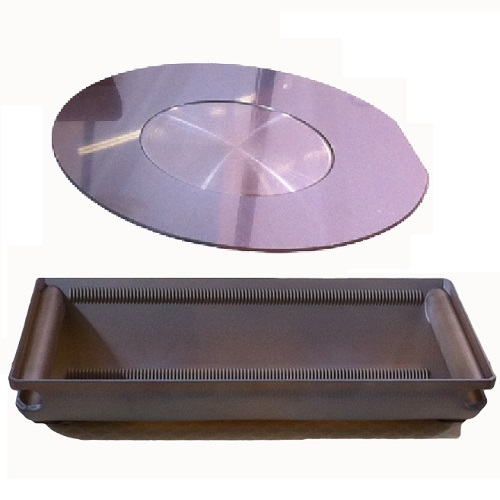

Category: Wafer Carrier/Susceptor – CVD Silicon Carbide

Lead Time: 8 to 10 weeks

Our goal is to exceed your expectations. We will offer you the best solution at the least cost for any CVD Silicon Carbide Wafer Carrier / Wafer Susceptor. Our extensive Knowledge base with our local sales engineers averaging over 25 years experience allow us to assist in developing a custom solution for your unique CVD Silicon Carbide Wafer Carrier / Wafer Susceptor requirements. Please contact us and advise how we can help! We provide custom designs to meet your specific semiconductor CVD Silicon Carbide Wafer Carrier / Wafer Susceptor size and shape requirements.

Forging the critical link between prototyping and production. Specializing in prototype work, we assure you finished CVD Silicon Carbide Wafer Carrier / Wafer Susceptor that meet development specifications.

Through our R&D process, CVD Silicon Carbide Wafer Carrier / Wafer Susceptor are also developed with production manufacturing in mind. By consulting with our engineers during the development process, you acquire the know-how that saves time and money when you need volume production. As production time approaches ,we are your best choice. Capable of handling any size job, we provide the security needed for making decisions that affect your customers.

Further, to keep pace with industry demands, our facilities are designed to grow and we continually add qualified personnel and the latest equipment.We also offer the flexibility of multiple shifts, rush order processing and JIT delivery. Add to this our commitment of providing superior materials and services, and you get the ideal manufacturing partner. Together we’ll get your CVD Silicon Carbide Wafer Carrier / Wafer Susceptor to market quickly and cost effectively.