Description

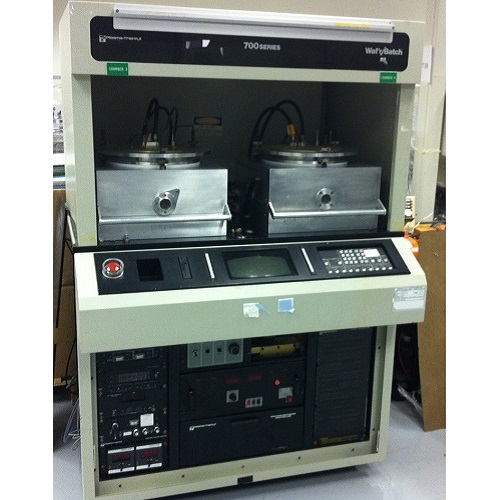

NRE-4000 without loadlock

NANO-MASTER’s NRE-4000 is a stand alone Reactive Ion Etching (RIE) system with showerhead gas distribution and water cooled RF platen. It has a stainless steel cabinet and a 13″ cylindrical aluminum chamber that opens from the top for wafer loading. It can accept up to 8″ (200 mm) wafers. The chamber has two ports, one with a 2″ window the other with a blank off for diagnostic equipment such end point detection. The chamber is extremely clean in design and reaches a base pressure in the 5×10-7Torr range or lower depending on the pumping package. It can be operated in the pressure range of 20mTorr to 8Torr. The standard pumping package has a 250 l/sec corrosive turbomolecular pump, sieve filter, and a 10cfm PFPE prepared backing pump. The RF power is provided by 600W 13.5MHz power supply, and an auto-tuner. The substrate DC bias is continuously monitored and reaches as high as -500V, which is important for anisotropic etching. The system is PC controlled recipe driven giving maximum flexibility to user while maintaining high reproducibility.

NRE-4000 with loadlock

The system is PC controlled which allows for complete automation of the system and recipes. The real time system pressure and DC bias are displayed in graphic format, while the flow and power are displayed in alpha numeric format. Four levels of authorization Auto, Engineering, Process and Maintenance prevents unauthorized use of the system while giving maximum flexibility to user for setting up recipes in Process mode and running in Auto mode with high reproducibility. Auto load and unload is available for single wafers and cassette to cassette. Other options include high temperature platens and a larger chamber to handle 12” (300mm) wafers.

- 13” aluminum hard anodized chamber

- Showerhead gas distribution

- Up to 200mm substrates

- MFC’s with SS gas lines

- DC Bias: up to -500V self bias, up to -1000V external bias

- Automatic pressure control

- 600W RF power supply with auto tuner

- Water cooled or heated (400°C) platen

- 250l/sec corrosive turbomolecular pump with suitable backing pump

- Fully automated PC based, recipe driven

- LabVIEW user interface

- Fully safety interlocked

Options

- NM-ICP downstream high density plasma source for high rate etching

- Plasma source for isotropic etching

- He backside cooling with mechanical clamp for DRIE

- Additional MFC’s

8 or 12 line Gas Box

8 or 12 line Gas Box- Single wafer and cassette to cassette auto load/unload

- Substrate cooling down to -20°C and heating up to 200°C

- Spectroscopic End Point Detector

- Electostatic chuck

- 12″ wafer chamber

- Dry Pump

- Dural chamber systems:

| NRP-4000 Dual PECVD/RIE System with ICP Source and Auto Load/Unload | PECVD/RIE System |

|

|

| RIE/Sputter System | Ion Beam / RIE System |

|

|

Applications:

- Compound Semiconductors

- GaAs sensor

- Photonics

- MEMS device fabrication

- Deep trenches in silicon etching

- Plasma dicing for advanced packaging

- Etching Visa for TSV fabrication

- High precision motion sensors

- Nano Scale etching and microfluidics

- Photo resist stripping

- Etching of dielectric, silicon-based, sputtered metals and DLC films

GENERAL SPECIFICATIONS

- Maximum Substrate Size: 8”

- Substrate Temperature Range: Up to 200°C

- Gas Lines: Heated and Electropolished

- MFCs: Up to 8 MFCs

- System Control: PC Controlled with LabVIEW and Touchscreen User Interface

- Loading and Unloding: Manual or Automatic

FACILITY REQUIREMENTS

- Power Input: 208V/380V/415V, 20A/Phase, 50/60Hz

- Chilled Water: 2gpm @ 50psi, 18°C

- Compressed Air: 1/4” Swagelok, 80-90 PSI

- Processed Gas: 1/4” Swagelok, 20 PSIG

- Nitrogen: 1/4“ Swagelok, 10 PSIG

- Exhaust (System): NW25

DIMENSIONS (Width ,Depth ,Height)

- NRE-4000 : 26” ,44” ,60”

- NRE-3500 : 26” ,26” ,60”

- NRE-3000 : 26” ,26” ,32”

| NRE-4000 | NRE-3500 | NRE-3000 |

|

|

|

The trademarks of the equipment and parts contained on this page belong to the Original Equipment Manufacturers.

Nano-Master Main Equipment: Thin Film | Etch | Cleaning | Space Simulation | Hybrid

SS10840

“>快速退火炉,速升溫退火爐,保护气氛快速退火炉,保護氣氛快速退火爐,快速退火爐,红外灯加热,红外灯快速退火,卤素灯加热,高温计,红外高温计,等离子去胶机,等离子刻蚀,深刻蚀,各向同性,各向异性,等离子清洗,溅射台,蒸发台,磁控溅射台,直流电源溅射,高频溅射,自动刻蚀机,自动去胶机,手动去胶机,手动刻蚀机,干法去胶机,湿法去胶机,干法刻蚀机,湿法刻蚀机,半导体设备,半导体旧设备,半导体中古设备,半导体前道工艺设备,半导体后道工艺设备,半导体前道设备,半导体后道设备,半导体量测仪器,半导体量测设备,美国制造,紅外線燈加熱,紅外線燈快速退火,鹵素燈加熱,高溫計,紅外線高溫計,等離子去膠機,等離子蝕刻,深刻蝕,各向同性,各向異性,等離子清洗,濺射台,蒸發台,磁控濺射台,直流電源濺射,高頻濺射,自動蝕刻機,自動去膠機,手動去膠機,手動蝕刻機,乾式去膠機,濕式去膠機,乾法蝕刻機,濕蝕刻機,半導體設備,半導體舊設備,半導體中古設備,半導體前道製程設備,半導體後道製程設備,半導體前道設備,半導體後道設備,半導體量測儀器,半導體量測設備,美國製造,Plasma Asher, Plasma Descum, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Matrix 105, Matrix 205, Matrix 303, Matrix 403,Matrix 106,Matrix 104, Matrix 102,Matrix 101, Matrix 10, System One Stripper, Model 105, System One Etcher, model 303, model 403,Matrix 1107, Plasma Etcher, Plasma Etching, Dry Etching, Dry Clean Plasma Asher, Plasma Descum, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Branson/IPC 2000, Branson/IPC 3000, Branson/IPC 4000, Barrel Asher, Barrel Etch, Barrel Etcher, Plasma Asher, Plasma Descum, Dry Clean, Downstream Asher,Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Gasonics Aura 1000, Gasonics Aura 2000, Gasonics Aura 3000, Gasonics L3510, Gasonics Aura 3010, Plasma Etcher, Plasma Etching, Dry Etching, Dry Clean,Gasonics AE 2001, Gasonics AE 2000LL Plasma Etcher, Plasma Etching, Dry Etching, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Plasma RIE ,Reactive Ion Etch System, Reactive Ion Etch System, Tegal 901e, Tegal 903e, Tegal 901e TTW, Tegal 915,Tegal 701,Tegal 703,Tegal 801,Tegal 803,Tegal 981e,Tegal 903e,Tegal 915, Tegal 965, Tegal 405, Tegal 401 Plasma Etcher, Please Etching, Dry Etching, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Lam AutoEtch 490, Lam AutoEtch 590, Lam AutoEtch 690, Lam AutoEtch 790, Lam Rainbow 4400, Lam Rainbow 4420, Lam Rainbow 4428, Lam Rainbow 4500, Lam Rainbow 4520, Lam Rainbow 4528, Lam Rainbow 4600, Lam Rainbow 4620, Lam Rainbow 4628, Lam Rainbow 4700, Lam Rainbow 4720, Lam Rainbow 4728, Plasma Etcher, Plasma Etching, Dry Etching, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Gasonics AE 2001, Microwave Etcher, Microwave Plasma Etcher, Microwave Etch, Downstream Plasma Etch Enviro,ENVIRO-1XaENVIRO-1Xa ,2CENVIRO-Optima,Luminous NA,NA-8000NA-1300NA-1500 ,Multifilm,NE-550EXaNE-950EX, APIOSNE-5700Deep, Oxide Etching ,NLD-570EXaRISE System,RISE Series,Cluster Systems,SME SeriesuGmni Series,SRH SeriesULDiS Series,SMV-500FRoll-coater,SPW SeriesIn-line Systems,SIV SeriesSDH-4550LR&D,CS-200, 300mm,ENTRON-EXENTRON-EX2,Evaporation Roll Coater,EW SeriesR&D/Pilot Production,Ei-5In-line Systems, Ei-H series,Si Processing,IMX-3500SOPHI-200/260 ,SiC,IH-860,Brazing Furnace,FB SeriesFHHn series ,Vacuum Sintering,FSC SeriesVacuum,Induction Melting,FMI Series,Vacuum Heat Treatment,FHB-60CFHV Series,Single-Substrate,CC Series,CME Series,In-line Systems, ULGLAZE Series,Lyophilizer,DFB Series,Micropowder Dry, UPD-400D,FM Series,DFR Series,Centrifugal Type,CEH-400B,ULVAC Perkin-Elmer 4400, Perkin-Elmer 4410, Perkin-Elmer 4450,Perkin-Elmer 4480, Perkin-Elmer 2400, Perkin Elmer 4400, Perkin Elmer 4410, Perkin Elmer 4450,Perkin Elmer 4480, Perkin Elmer 2400, Sputter, Magnetron Sputter, Diode Sputter, DC Sputter, RF Sputter, DC Magnetron Sputter, RF Magnetron Sputter, Co-sputter, Reactive Sputter, MRC, MRC 603, MRC 903, MRC 602, MRC 902, MRC 604, MRC 904, MRC 924, Plasma Etch, Dry Clean, Bias Function, Cathode, Load lock, Degas, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment,, Thin Film, Metal Thin Film, Thin Film Deposition, PVD, Physical Vapor Deposition Nordson MARCH Plasmatreat Bdtronic Panasonic PVA TePla Diener Electronic Vision Semicon Samco Inc. Tantec SCI Automation PINK GmbH Thermosysteme Plasma Etch Shenzhen OKSUN. Plasma Surface Treating Equipment : Nordson MARCH, bdtronic, Diener electronic, AcXys Technologies, Europlasma, ME.RO, Tantec, Plasmatreat, Plasma Etch, PINK GmbH Thermosysteme, Kalwar Group, Arcotec, Shenzhen OKSUN. Helium Leak Detector: Mass Spectrometer Leak Detector, INFICON, Agilent, Pfeiffer Vacuum, Leybold, Shimadzu, AnHui Wanyi, Edwards Vacuum, ULVAC, Canon Anelva, VIC Leak Detection

Plasma Cleaners,Semiconductor Automotive Electronics Tabletop Type Large Chamber Type Nordson MARCH Plasmatreat Bdtronic Panasonic PVA TePla Diener Electronic Vision Semicon Samco Inc. Tantec SCI Automation PINK GmbH Thermosysteme Plasma Etch , Semiconductor Mass Flow Controller : HORIBA Fujikin MKS Instruments Sevenstar Hitachi Metals, Ltd Pivotal Systems MKP AZBIL Bronkhorst Lintec Kofloc Brooks Sensirion ACCU Sierra Instruments, Dry Etching Equipment, Lam Research TEL Applied Materials Hitachi High-Technologies Oxford Instruments ULVAC SPTS Technologies GigaLane Plasma-Therm SAMCO AMEC NAURA , Nano-master, Allwin21, SemiStar, Inductively Coupled Plasma (ICP) Etchers, Lam Research TEL Applied Materials Hitachi High-Tech Oxford Instruments SPTS Technologies Plasma-Therm GigaLane SAMCO Corial AMEC NAURA Planar ICP Source, Cylindrical ICP Source, Semiconductors; Dielectrics; Metals; Polymers;Handheld Plasma Cleaner : Allwin21, SemiStar, Innoclean, Techu Scientific, Ja0755, PLAUX, Relyon Plasma GmbH, Plasma Pipette, Plasma Etch, Harrick Plasma, Diener Electronic GmbH, PVA TePla AG, HRL Laboratories. Reactive Ion Etch (RIE) Systems:Oxford Instruments; SAMCO Inc.; Plasma-Therm; NANO-MASTER; Lam Research; Nordson MARCH; AMEC; Trion Technology; SENTECH; Plasma Etch Inc.; Torr International; Korea Vacuum Tech; Beijing Chuangshiweina Technology。