Description

NLE-4000 Cross Section with RF biasing for Shower Head with Planar ICP source

The NANO-MASTER NLE-4000 is a stand-alone hybrid PAALE/PEALD system for performing plasma-enhanced atomic layer deposition (PEALD) as well as plasma-assisted atomic layer etching (PAALE). Both processes can be performed in a single chamber without any mechanical reconfiguration. It is CE and SEMI Standards-compliant. The system is controlled with LabVIEW software and features three-level password-controlled user authorization using a touch-screen monitor. The system is fully automated, safety-interlocked, recipe-driven, with status indicators and graphic and alphanumeric displays. Widely used in na-noscale fabrication, MEMS, quantum devices, and advanced semiconductor technologies, our hy-brid PAALE/PEALD system is able to provide damage-free Plasma Assisted Atomic Layer Etching. Nano-Master ALE systems provide soft Atomic Layer Etching using our unique Planar Inductive Coupling Plasma (ICP) source.

Atomic Layer Etching (ALE) is a precise material removal technique used in semiconductor manu-facturing that operates at the atomic level. This method ensures ultra-thin layer removal with high fidelity, allowing for selective etching of specific materials while minimizing damage to adja-cent areas. ALE enables precise control over surface morphology, making it essential for advanced device architectures. Characterized by low etch rates, it is ideal for applications requiring meticu-lous layer management typically in the order of monolayers. The process involves alternating cy-cles of surface modification and etching, which enhance uniformity and reproducibility. Addition-ally, ALE is compatible with a variety of materials, including silicon, metals, and dielectrics, and it reduces substrate damage, preserving electrical properties.

- Patented Dual capability (PAALE/PEALD) in the same chamber without any mechanical reconfiguration.

- For the ALE process, only radicals from the planar ICP source are generated for adsorption ( Patented)

- Soft Ar etching is performed by applying RF to the shower head to remove the adsorbed radicals for ALE.

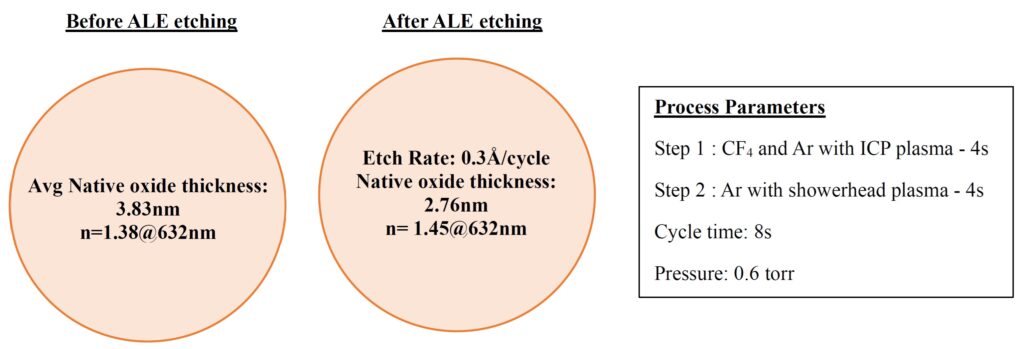

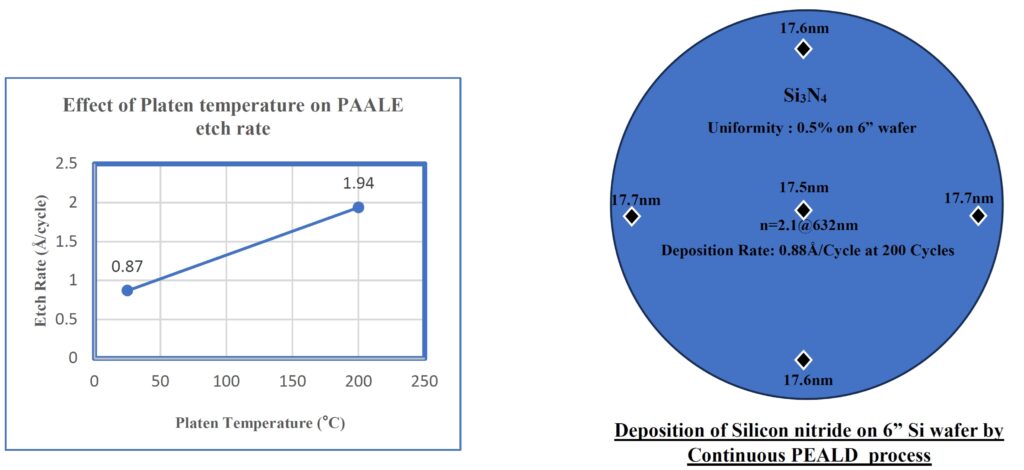

- Precise Atomic layer etching of 0.8Å to 1Å /cycle

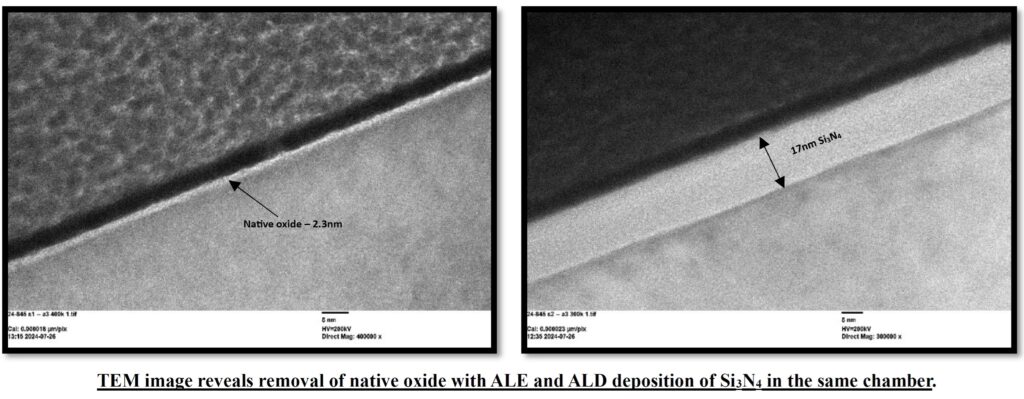

- Removing native oxide with PAALE and depositing the passivating layer Si3N3 with PEALD in the same chamber without exposing it to the atmosphere.

- Minimal chamber volume for fast cycle time and throughput

- Continuous ALD process for depositing passivating layer with less than 1Å uniformity

- Plasma contact with the substrate is eliminated with Nano-Master’s patented ALD process.

- CE and SEMI standard

- 13″ Ni-plated Al chamber w/ heated chamber wall

- 2×10-6 Torr base pressure attained with turbo pumping package

- NM-Planar ICP source with shower head gas distribution.

- High surface ALD filter at the chamber exhaust

- Level precursor distribution

- Up to 8″ substrate, heated upto 400℃ ( Biasble) for ALE process

- RF biasing for shower head – Soft ALE etching

- Onboard precursor glovebox for ALD cylinders

- Separate gas pod for toxic gasses with gas leak sensors for ALE gasses

- Up to seven 50cc precursor cylinders

- 360 l/sec Heated maglev turbomolecular pump

- 2×10-6 torr base pressure

- Fast pulse gas delivery valves

- Large area filter to capture unreacted precursors

- High aspect ratio structure coating

- MFC’s with electropolished gas lines and pneumatic shut-off valves

- Fully automated PC based, recipe driven

- LabVIEW user interface

- EMO protection and Computer-controlled safety interlocks

- 26″ x 44″ footprint with enclosed panels ideal for cleanrooms

Options

- Separate gas pod for reactive/toxic gasses with gas leak sensors

Applications:

- Precise etching of native oxide

- Power Electronics

- Etching 2-D Materials

The trademarks of the equipment and parts contained on this page belong to the Original Equipment Manufacturers.

Nano-Master Main Equipment: Thin Film | Etch | Cleaning | Space Simulation | Hybrid

SS10840