Atomic layer deposition (ALD) is an important technique for depositing thin films for a variety of applications. ALD provides precise thickness control and conformal deposition for high aspect ra-tio applications, exceeding the level of other deposition methods. The sequential, self-limiting surface reactions in ALD produce a non-statistical deposition as precursor flux randomness is a non-factor. As a result, ALD films are extremely smooth, continuous, and pin-hole free, which result in excellent film properties. In addition, the ALD process can be scaled to large substrates.

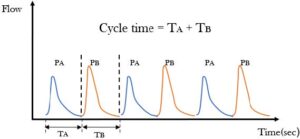

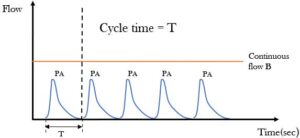

NANO-MASTER’s patented continu-ous flow process allows ALD process times to be cut in half when com-pared to typical PEALD systems. This is achieved by continuously flowing a precursor gas as another is pulsed and is possible due to NANO-MAS-TER’s planar ICP source.

Patent No.: US 10,366,898

| Typical PEALD Process | NANO-MASTER’s Continuous Flow Process |

|

|

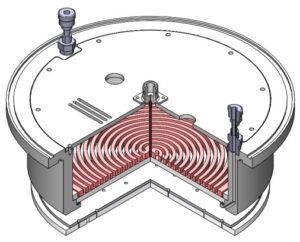

NANO-MASTER’S PLANAR ICP SOURCE: NANO-MASTER’s planar ICP source is a novel four antenna coil design that allows for scalability while maintaining a small footprint. The NANO-MASTER ICP source has a volume of 1.6L, which is up to 10 times smaller than typical cylindrical sources. Due to the source’s smaller volume, less RF power is re-quired to generate the same ion density as typical cylindrical sources. In addition, a downstream ICP source kills plasma in a short distance using a grounded metal and ceramic plate, which minimizes film damage.

NANO-MASTER’S PLANAR ICP SOURCE: NANO-MASTER’s planar ICP source is a novel four antenna coil design that allows for scalability while maintaining a small footprint. The NANO-MASTER ICP source has a volume of 1.6L, which is up to 10 times smaller than typical cylindrical sources. Due to the source’s smaller volume, less RF power is re-quired to generate the same ion density as typical cylindrical sources. In addition, a downstream ICP source kills plasma in a short distance using a grounded metal and ceramic plate, which minimizes film damage.

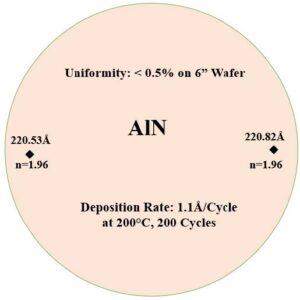

Deposition of ALN, ALD SAMPLE DATA

Parameters

➢Precursors: TMA & N2 plasma

➢Cycle Time: 5s

➢Pulse Time: 20ms

➢RF Power: 200W

➢Pressure: 0.27 Torr

Results

➢Deposition Rate: 1.1Å/Cycle

➢Uniformity: <0.5%